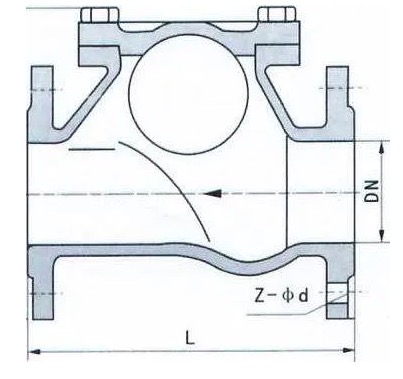

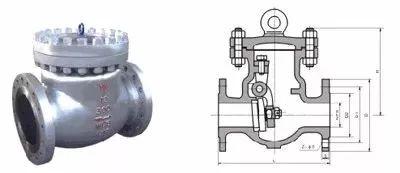

The check valve is one kind of accessory widely installed in various industrial pipeline systems. Check valve can be divided into wafer type check valve, lift type check valve, wafer butterfly type check valve, line check valve, compression check valve.

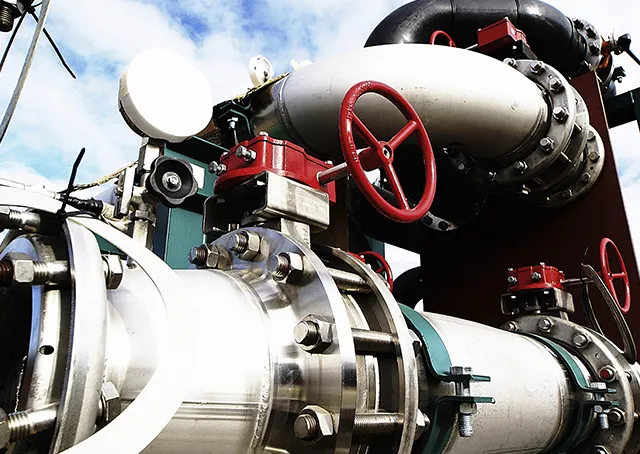

It has three main functions, preventing the back-flow of the medium, preventing the reverse rotation of the water pump and the driving motor, and discharging the container medium.Check valves can be used in pipeline systems in petroleum, chemical, metallurgical and other industrial sectors.

Advantages of check valves:

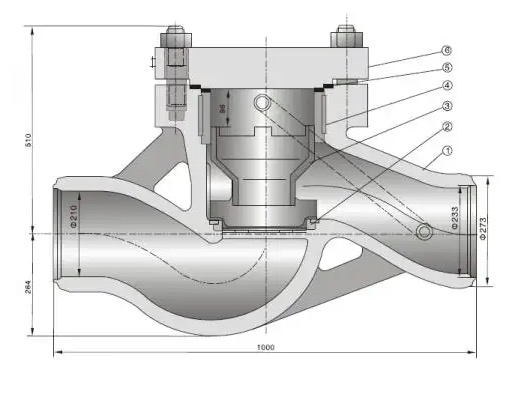

The main advantage of the check valves is its function, which can prevent the back-flow of the internal medium and prevent the back-flow of medium from contaminating other mediums, for example, the check valve installed in water supplying pipe line system can prevent the tap water from being contaminated, and also prevent the running water from flowing out of the pipes.

Disadvantages of check valves:

The disadvantage of check valves is that due to the large fluid resistance, the medium channel in the valve body is relatively tortuous, which is likely to cause a certain energy loss, which may affect the water pressure and flow rate of the internal medium.