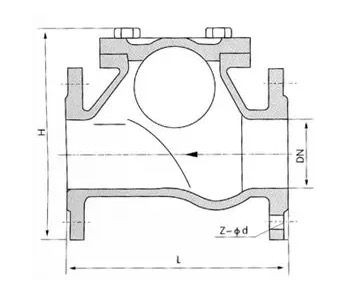

Ball type check valve, also known as ball type one way valve, ball type non return valve, ball check valve, floating ball type check valve, floating rubber ball type check valve, rubber ball check valve, is the combination of ball valve and check valve. The ball type check valve consists of a valve cover, a rubber covered steel ball, a cone and other parts. The ball check valve is to use the rubber ball to roll in a short stroke in the ball cover to realize the opening and closing of the check valve, thereby, which can realize the anti-reverse flow effect of the ball type check valve.

the structural advantages of floating ball type check valve:

- the surface of the valve disc is lined with rubber, and the dimensional accuracy and surface roughness of the ball can be controlled by a rubber lined mold. The processing accuracy requirements of the ball body is reduced, and it can be reused, thereby reducing the cost of the valve disc.

- The surface rubber of the steel ball can be elastically deformed, which can absorb and reduce vibration and play a certain buffering role.

- The ball body of the floating ball type check valve adopts a hollow structure, which is light in weight and can reduce the impact force of the valve disc on the valve seat when the ball check valve is closed;

- The inner diameter of the ball track is designed to be larger than the pipe diameter of the corresponding flange, which increases the flow section, reduces the medium resistance and reduces the pressure;