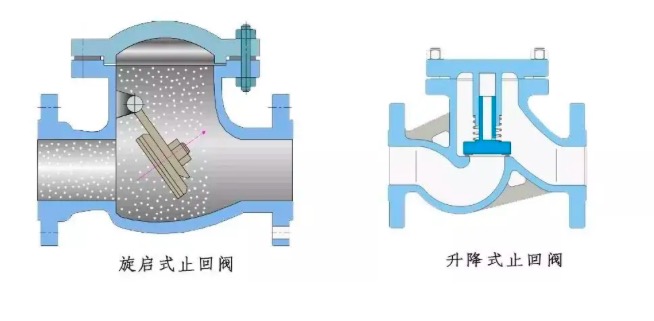

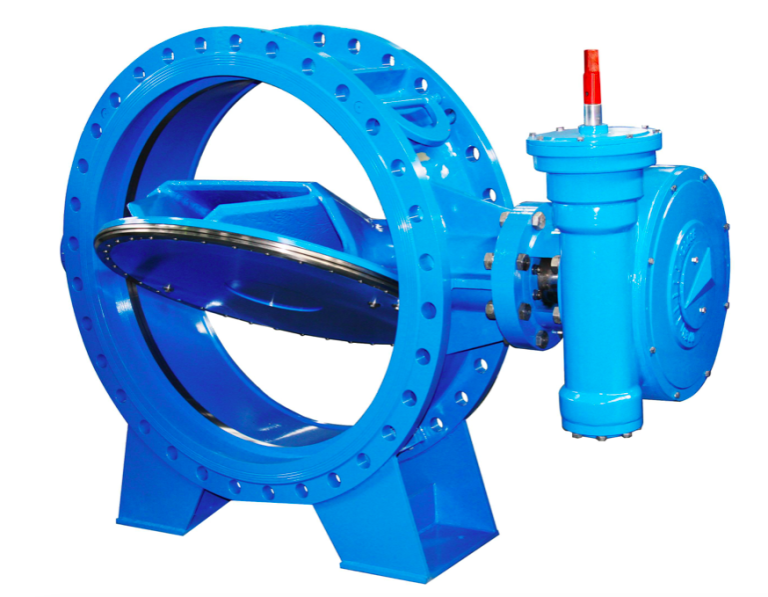

The swing type check valve opens and closes automatically by the action of fluid pressure and the weight of the disc. the valve disc of the swing check valve rotates around the rocker shaft in the body cavity instead of lifting up and down. The swing type check valve can also play a role in preventing the back flow of the mediums.

Swing type check valve can be divided into three types: single disc swing check valve(single plate swing check valve), double disc swing check valve(dual disc swing check valve, or dual plate swing check valve), and multi disc swing check valve.

Installation for swing check valve:

1. swing check valve is usually installed in horizontal pipe lines, and is often in a full opening state when the swing check valve is working.

2. Swing type check valve should be preferentially installed on horizontal pipelines, and swing check valve can be also installed on vertical pipe lines where the medium in the pipe flows from bottom to top;

3. The following work should be done before installation:

3.1. remove the stuffy cover and foam board at the both ends of the valve channel, clean the inner cavity, and remove the grease;

3.2. peel off the oil paper on the surface of the valve disc of the swing check valve, and remove the grease on the surface of the valve disc of the swing check valve;

4. The flow direction of the medium must be restricted during installation of swing check valve;

5. The medium passing through the pipeline should not contain hard particles, so as not to damage the sealing surface of the swing check valve;

6. Before leaving the factory, the swing check valve has been inspected and tested one by one, and has been qualified, so the customer can directly do the pressure test or install the swing check valve directly;

Swing check valve can be divided into three types: single disc swing check valve, dual disc swing check valve(double disc swing check valve), multi disc swing check valve.