Check valve is one automatic industrial valve, also known as one way valve, back pressure valve, non return valve, cut off valve. According to different working environments, check valve can be divided into several types: the more commonly used ones are: slow close check valve, stainless steel check valve, forge steel check valve, flue check valve,etc.

What is the difference between slow closing check valve and other check valves, like rubber disc check valve, or stainless steel check valve?

The function of the check valve is to prevent the back flow of the medium in the pipeline. It is suitable for various pipelines with nominal pressure PN1.0MPa~42.0MPa、Class150-2500;nominal diameter DN15~1200mm, NPS1/2~48;working temperature -196~540℃, to prevent the back flow of the medium. By choosing different materials, check valve can be applied to various mediums, such as water, steam, oils, nitric acid, acetic acid, strong oxidizing medium and urea.

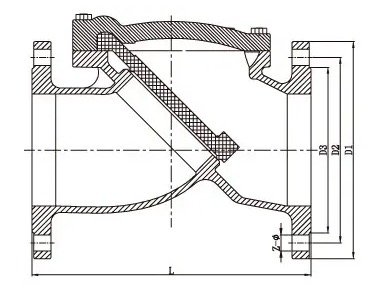

Introduction of rubber disc check valve:

The plate of H44X series of rubber disc check valve is made of steel plate, steel rod and reinforced nylon cloth as the backing, and the outer layer is covered with rubber. The valve flap can open and close for more than 1 million times. The rubber disc check valve is using full flow area design, which has small head loss, is not easy to accumulate debris, and is easy and convenient to maintain. The rubber disc check valve is mainly used horizontal installation of water supply and drainage system, and can be stalled at the water outlet of the pump to prevent back flow of medium and water hammer from damaging the water pump; Rubber disc check valve can also be installed on the bypass pipe of the water inlet and outlet pipes of the reservoir to prevent the back flow of the pool water from flowing back into the water supplying system;

Brief introduction of stainless steel check valve:

Stainless steel check valve can be also used on lines supplying auxiliary systems where the pressure may rise above the main system pressure. Stainless steel check valve can be applied to pipelines of various mediums according to different materials used.

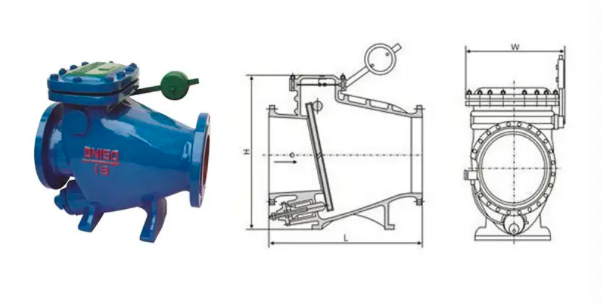

Brief introduction of slow close check valve:

Slow closing check valve is one of check valves, is mainly composed of valve body, valve cover, valve plate, balance weight, piston and regulating valve. Slow closing check valve is used for water supply and drainage pipelines, and is installed at the water pump outlet to prevent the back flow of the mediums, and destructive water hammering.

The nominal pressure for slow close check valve is 1.0~2.5MPa. The nominal diameter of slow closing check valve is 40~800mm. Its applicable mediums are water, weak corrosive liquid, sea water and waste water. The working temperature for slow closing check valve is 0~80℃, if necessary, its working temperature can go up to 200℃. the flange standard for slow closing check valve is GB/T 17241.6 GB/T9113. its testing standard is GB/T 13927 AP1598.

The slow closing check valve has the advantages of light valve disc, large opening degree, significant power saving effect, small fluid resistance, reasonable water hammer elimination structure, reliable sealing performance, wear resistance, long service life, stable operation, no vibration and no noise.