Industrial valves are widely used in various pipeline systems to connect and cut off the mediums, with different materials used like stainless steel, WCB, ductile cast iron, forged steel,brass, etc, the industrial valve can be used for different mediums. Today we are going to compare the difference between cast steel valves and forged steel valves:

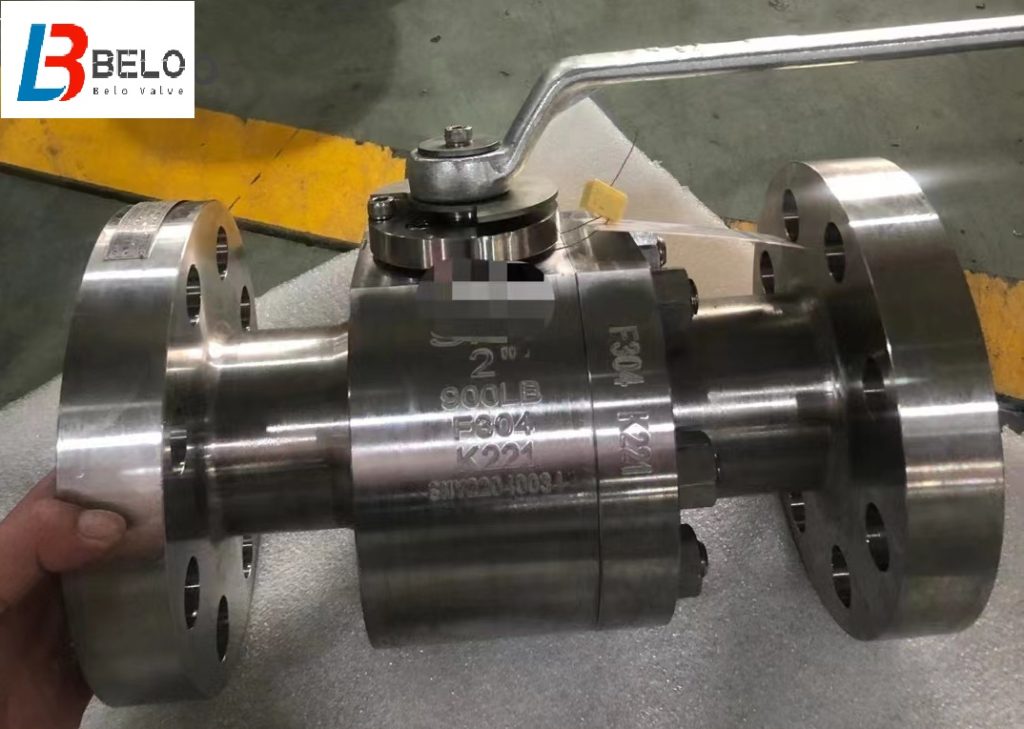

1. First of all, one of the differences between cast steel valves and forged steel valves is the difference in material(mainly in the density of the steel of the valve body, the density of forged steel is greater than that of cast steel), forged steel valves and cast steel valves are mainly made of steel, but they are having different processes and different processing forms; cast steel valves are formed by liquid pouring molds, while forged steel valve is a plastic deformation process. Forged work-pieces can improved the strength of the internal structure of the organization, with uniform grains and good mechanical properties. In general, important stressed work-pieces are forged, casting can cause tissue segregation and tissue defects in work-pieces. Of course, cast steel valves have their advantages, which can form complex work-pieces, but high forging technology and high economic costs make it difficult to open molds. In this case, we,Belo Valve,as a more than 15 years of valve manufacturer, advice customers to choose cast steel valves.

2. Definitely, forged steel valve is better than cast steel valve. Forged steel valve can withstand large impact forces. The forged steel valve’s physical properties of plasticity, toughness, and pressure strength are also much higher than those of cast steel valves. But the nominal diameter of forged steel valves is relatively small, generally under DN50, the reason is that the technical requirements for forging equipment used in forging steel is much higher than that of casting steel equipment. And the gap between economic and technical aspects is large. The nominal pressure level of cast steel valve is relatively low, the commonly used nominal pressure are PN16,PN25,PN40, 150LB-900LB. Common pressure for forged steel valves are: PN100, PN160, PN320, 1500LB-3500LB,etc. The casting steel process is mainly used to manufacture some valve work pieces with complex shapes that are difficult to forge or cut; the forged steel process is mainly used for work pieces that require high strength and plasticity.