Butterfly valve, also called flap valve, is one kind of industrial regulating valve with simple structure. The butterfly valve that can be used for on-off control of low pressure pipeline medium refers to a valve whose closing part is a disc(or called butterfly plate), which rotates around the valve shaft to achieve opening and closing of the butterfly valve.

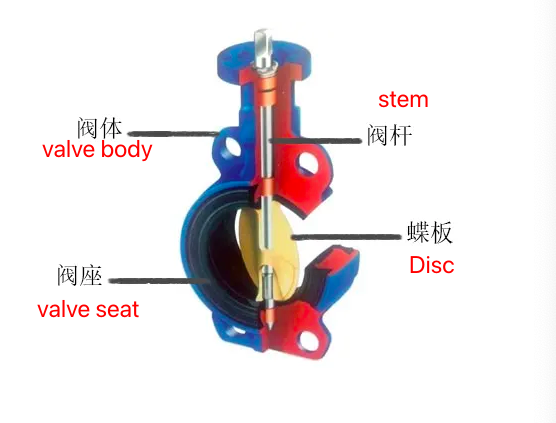

What components butterfly valve has:

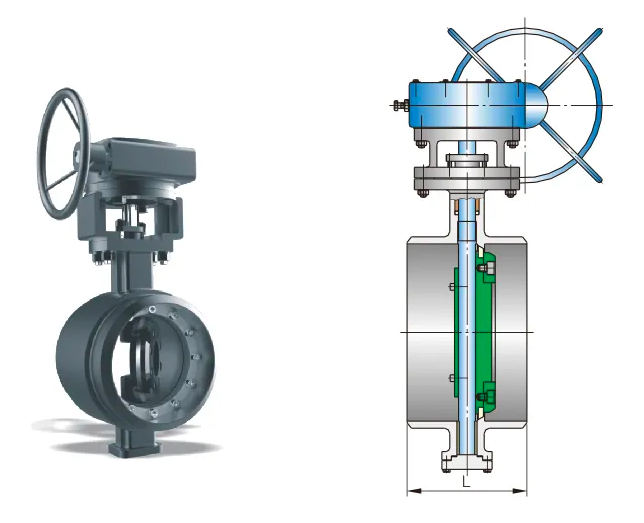

The structure of a butterfly valve is simple, which mainly consists of valve body, valve disc, valve seat, valve stem, and the operating device(like manual lever, worm gear box, electric actuator, pneumatic actuator).

What types butterfly valve has:

With different structure, butterfly valve has concentric butterfly valve and eccentric butterfly valve;

According to body material, we have stainless steel butterfly valve, ductile cast iron butterfly valve, WCB butterfly valve, gray iron butterfly valve;

According to end connect, butterfly valve is divided into wafer type butterfly valve and flange type butterfly valve;

With different sealing material used, there are soft sealing butterfly valve and metal hard sealing butterfly valve;

Applications of butterfly valve:

Butterfly valve can be used to control the flow of various types of fluids such as air, water, steam, various corrosive mediums, mud, oil, liquid metal and radioactive medium. Butterfly valve mainly plays the role of cutting and throttling on the pipeline;

The opening and closing part of butterfly valve is a disc-shaped butterfly plate, which rotates around its own axis in the valve body to achieve the purpose of opening and closing or adjustment.

How butterfly valve connects with the pipeline?

Whether the selection of the connection method between the butterfly valve and the pipeline or equipment is correct or not will directly affect the probability of dripping, leaking of butterfly valve in the pipeline;

The common butterfly valve connection methods include: flange connection, wafer connection, butt welding connection, and grooved connection(or called clamp connection);

1. flange connect butterfly valve

Flange connection is that the butterfly valve has flanges at both ends, corresponding to the flanges on the pipeline, and is installed in the pipeline by bolting the flanges. Flange connection is the most commonly used connection form in butterfly valves. Flanges are divided into raised-face flange(RF), flat face flange(FF), male and female flange(MF);

2. wafer connection butterfly valve

The wafer type butterfly valve is installed in the middle of the two flanges. There are usually positioning holes on the wafer butterfly valve to facilitate installation and positioning. The connection form of the wafer butterfly valve and the two pipes at both ends is directly clamped together with bolts.

3. Butt welding connection butterfly valve

The two ends of the butt welding butterfly valve are processed into a butt welding groove according to the butt welding requirements, which corresponds to the welding groove of the pipeline, and is fixed on the pipeline by welding;

4. grooved connection butterfly valve (or called clamp connection butterfly valve):

The grooved connection butterfly valve is a quick connect valve that requires only two bolts; grooved connection is suitable for low pressure valves that are frequently disassembled. Such as fire fighting valves(like we have grooved fire fighting gate valves, grooved fire fighting butterfly valves, grooved fire fighting signal butterfly valves, grooved fire fighting signal gate valves, grooved fire fighting check valve, grooved fire fighting silencing check valve, grooved controlling valves;

For more information about butterfly valves or ball valves, please contact us :