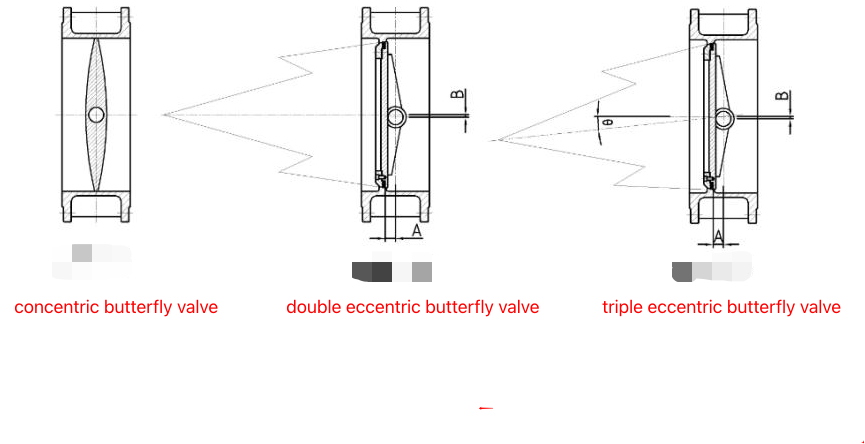

Double eccentric butterfly valve is one improved design on the basis of the single eccentric butterfly valve, which is most widely used at present. The structural feature of double eccentric butterfly valve is that the axis center of the valve stem deviates not only from the center of the disc plate, also from the center of the valve body. The design of double eccentric enables the disc plate to leave the valve seat quickly after the valve is opened, which greatly eliminates unnecessary excessive extrusion and scratching between the disc plate and the valve seat, reduces the opening resistance, wear and improves the service life of the valve seat. The greatly reducing of the scraping phenomenon enables the double eccentric butterfly valve to use metal seat as the sealing material, which improves the applications of butterfly valves in the high temperature field. However, because its sealing principle is a position sealing structure, that is, the sealing surface of the disc and the valve seat is in lineal contact, the elastic deformation caused by the disc pressing the valve seat produces a sealing effect, so it has a high requirement for the closing position(especially for metal valve seat), its pressure bearing capacity is low, which is why traditionally people think that butterfly valves are not resistant to high pressure and have large leaking problem.

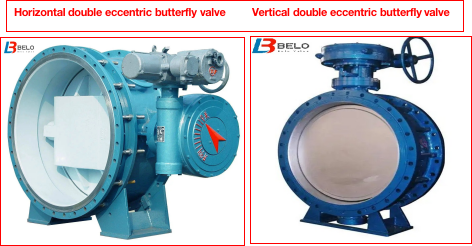

Types of double eccentric butterfly valve:

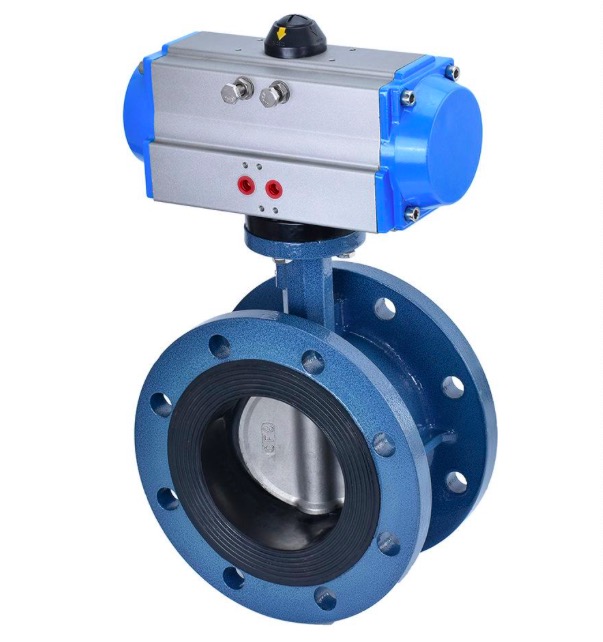

Double eccentric butterfly valve is one kind of high performance butterfly valve. With different operating device, there are manual double eccentric butterfly valve, worm gear box operated double eccentric butterfly valve, pneumatic operated double eccentric butterfly valve, electric actuated double eccentric butterfly valve.

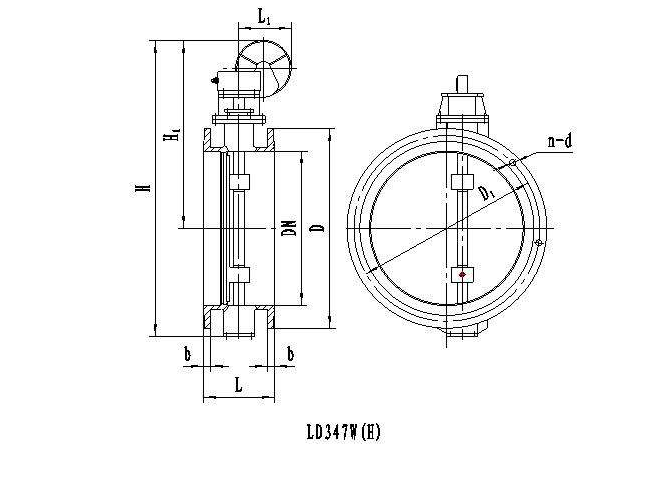

For different end connect, there are wafer type double eccentric butterfly valve and flange type double eccentric butterfly valve;

For sealing materials types, there are soft sealing double eccentric butterfly valve and metal hard sealing double eccentric butterfly valve;

For different body material used, there are ductile iron double eccentric butterfly valve, cast steel double eccentric butterfly valve, stainless steel double eccentric butterfly valve;

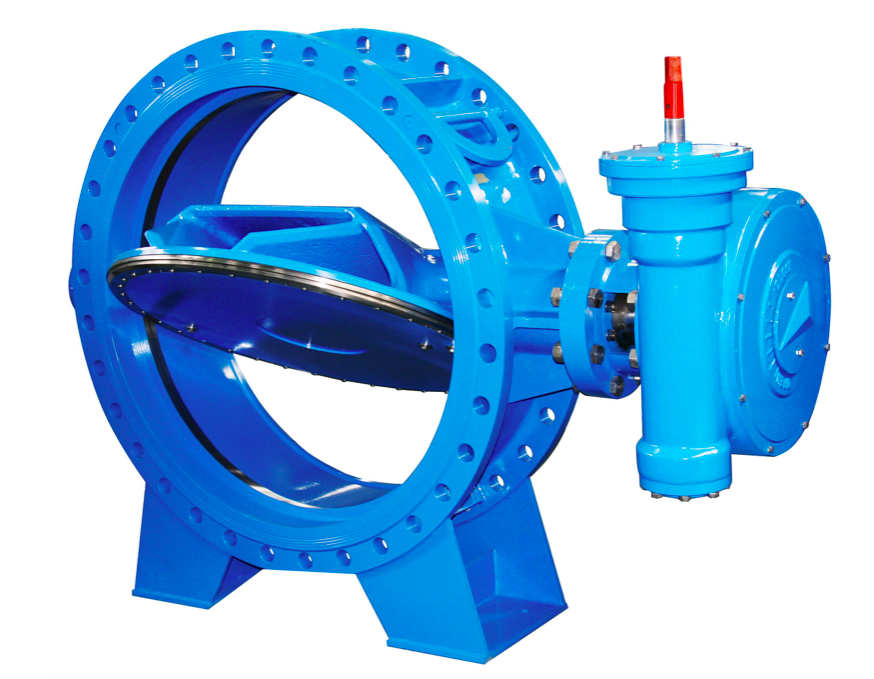

The nominal diameter range of double eccentric butterfly valve is DN50-DN3600MM, its nominal pressure range is PN0.1-PN10Mpa.

Belo Valve is a professional design, manufacturing and marketing company for double eccentric butterfly valves, the double eccentric butterfly valves developed and manufactured by Belo Valve have compact structure, reliable sealing performance, long service life,are easy and convenient to operate, have been widely used in water plants, power plants, steel plants, paper making, chemical industry, food industry, and other pipeline systems for water supply and drainage, as a adjusting and cutting off device.

Advantages of double eccentric butterfly valve:

① Double eccentric butterfly valve adopts the special double eccentric design, which becomes tighter and tighter when the valve is closing and has reliable sealing performance;

② the sealing material of double eccentric butterfly valve is made of stainless steel, nitrile oil-resistant rubber, and EPDM sanitary grade rubber, which has a long service life.

③ the sealing rubber ring of double eccentric butterfly valve can be placed on the valve body or on the valve plate, which makes the double eccentric butterfly valve to be suitable for different mediums.

④ the double eccentric butterfly valve has high strength, large flow area and small flow resistance;

⑤ the whole body of the double eccentric butterfly valve is coated with epoxy paint, which can effectively prevent corrosion and is non toxic and harmless. As long as the sealing material of the valve seat is replaced, the double eccentric butterfly valve can be used for different mediums;

⑥ the double eccentric butterfly valve has bidirectional sealing effect. It is not limited by the flow direction during installation, nor is it affected by the spatial position, and it can be installed in any direction.

Applications of double eccentric butterfly valve:

Double eccentric butterfly valve(double offset butterfly valve) is one kind of high performance butterfly valve, is mainly used for drainage of water plants, power plants, steel plant smelting, chemical industry, water treatment engineering, environmental facilities construction,etc, especially for water pipelines as a adjusting and shutting off device. Compared with concentric butterfly valve, double eccentric butterfly valve is more resistant to high temperature and high pressure, has longer service life, and better stability.

for more informations about double eccentric butterfly valves, technical parameters or price, do not hesitate to contact us: