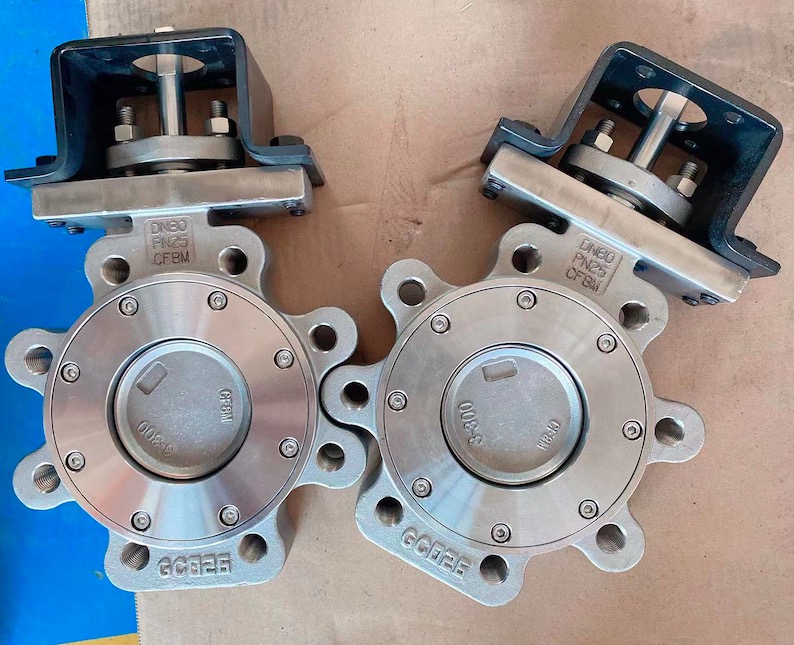

Belo Valve is supplying wafer, lug type high performance butterfly valves, whose body material can be WCB, stainless steel, or bronze.

A high-performance butterfly valve is a valve designed with special features to provide maximum flow control for a variety of applications. These valves are available in different types and sizes, but they all provide superior performance and reliability compared to standard butterfly valves. In this product description, we will discuss the characteristics, types, applications, and advantages of high-performance butterfly valves.

Definition of high performance butterfly valve:

A butterfly valve is a type of valve that uses a disc-shaped valve closure to regulate fluid flow. It features a rotating disc or plate that is mounted on an axis in the middle of the valve, which rotates to control the flow of the fluid. A high-performance butterfly valve is an advanced variant of this basic design, which is engineered to deliver superior performance in terms of accuracy, durability, and long-term reliability.

Types of high performance butterfly valve:

There are different types of high-performance butterfly valves available in the market, each with its unique features and benefits. Some of these include:

1. Triple Offset Butterfly Valve: This type of valve features a metal-to-metal seat and three offsets in the disc design to prevent seat wear, reduce torque, and improve sealing performance.

2. High-Pressure Butterfly Valve: This type is designed to handle high-pressure applications, typically up to 1500 PSI, making it ideal for oil and gas, chemical, and power generation industries.

3. Bi-Directional Butterfly Valve: This type is suitable for applications where flow can occur in both directions, such as in water distribution systems or HVAC systems.

4. Pneumatic Butterfly Valve: This type is actuated by air pressure and is used in applications where precise control and fast response time are required.

5. Electric Butterfly Valve: This type is operated by an electric motor and is suitable for applications that require remote operation and automation.

Characteristics of high performance butterfly valve:

High-performance butterfly valves are engineered with advanced features and designs to deliver superior performance and reliability. Some of the key characteristics of these valves include:

1. Excellent Flow Control: High-performance butterfly valves offer a superior flow rate compared to standard valves, ensuring precise and rapid control of the flow.

2. Low Torque: These valves require less torque to operate, reducing the effort required to open and close the valve.

3. Durable Materials: High-performance butterfly valves are made of high-quality materials that offer high resistance to wear, abrasion, and corrosion, ensuring long-term reliability.

4. Tight Shut-Off: These valves offer a tight shut-off, minimizing leakage and pressure drop.

Applications of high performance butterfly valve:

High-performance butterfly valves are used in a wide range of applications across various industries. Some of the common applications of these valves include:

1. Oil and Gas Industry: High-performance butterfly valves are used for a range of applications in the oil and gas industry, including compressor stations, pipelines, and storage tanks.

2. Chemical Industry: These valves are used in the chemical industry for processes such as transfer of chemicals and for applications involving corrosive or harsh fluids.

3. Power Generation: High-performance butterfly valves are commonly used in power generation plants for applications such as steam isolation, turbine bypass, and cooling water control.

4. Water Treatment: They are used in water treatment plants for water distribution, treatment, and purification applications.

Advantages of high performance butterfly valve:

High-performance butterfly valves offer several advantages over standard butterfly valves, including:

1. Superior Performance: These valves offer excellent flow control, low torque, tight shut-off, and enhanced durability, providing superior performance and reliability.

2. Lower Maintenance: The design of high-performance butterfly valves reduces the need for frequent maintenance and replacement, saving time and money.

3. Cost-Effective: High-performance butterfly valves offer a cost-effective alternative to other valve types as they are generally less expensive.

4. Easy to Install: These valves are easy to install and can be configured to meet specific application requirements.

In conclusion, high-performance butterfly valves are a reliable and cost-effective solution for a variety of flow control applications. There are different types of high-performance butterfly valves available, each with its unique features and benefits. These valves offer superior performance, lower maintenance, and cost-effective solutions for various industries, making them an excellent choice for flow control applications.