When it comes to maintaining optimal fluid flow control in plumbing systems, the choice of gate valves is crucial. Ductile iron EPDM lined DIN F5 resilient seated rising stem flanged gate valves have quickly gained popularity as an efficient solution. This article aims to delve into the features and benefits of these gate valves, highlighting their significance in ensuring seamless operations within plumbing networks.

Belo Valve can supply DIN F5 rising stem flange gate valves, and DIN F5 non rising stem flange gate valves, with ductile iron as body material and EPDM+ductile iron as the plate and seat sealing material, the diameter range of those DIN F5 resilient seated rising stem gate valves and DIN F5 resilient seated non rising stem gate valves can be DN50-DN300, and its pressure rate can be PN10 and PN16. if you are looking for DIN F5 gate valves supplier, or you want to know the DIN F5 gate valve prices, you can contact Belo Valve direct.

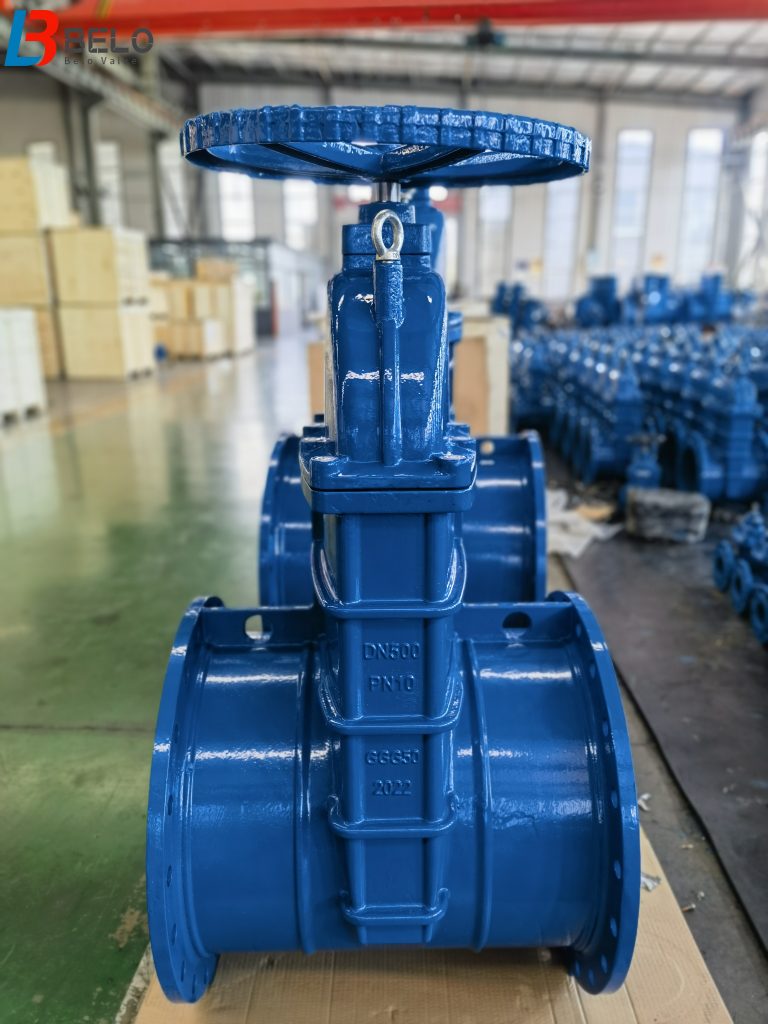

How DIN F5 resilient seated rising stem flanged gate valve looks like:

Main advantages of ductile iron DIN F5 resilient seated rising stem flanged gate valves:

1. Strong and Durable Construction:

Ductile iron is renowned for its robustness and durability, making it an ideal material for gate valves. These ductile iron DIN F5 rising stem flanged gate valves are designed to withstand high-pressure conditions and heavy-duty applications commonly found in industrial and commercial plumbing systems. With excellent tensile strength and resistance to corrosion, the ductile iron construction ensures long-term reliability and reduces the need for frequent maintenance.

2. Reliable Sealing Mechanism:

Equipped with an EPDM lining, these DIN F5 resilient seated rising stem flanged gate valves feature a resilient seated design that ensures a tight seal even under varying pressure conditions, can realize zero leaking effect. This superior sealing mechanism minimizes the risk of leakage, providing optimal flow control throughout the plumbing system. The EPDM liner also offers excellent resistance against chemicals, weathering, and abrasion, prolonging the valve’s lifespan.

3. Rising Stem for Easy Visual Inspection:

Unlike non-rising stem designs, ductile iron EPDM lined resilient seated rising stem flanged gate valves allow for easy visual inspection of the gate valve’s position. The valve stem rises and lowers as the gate valve opens and closes, providing an accurate indication of the valve’s operational status. This feature simplifies troubleshooting and maintenance activities, saving time and effort.

Appearance difference between DIN F5 rising stem flanged gate valve and DIN non rising stem flanged gate valve:

4. Flanged Connection for Quick Installation:

The flanged ends of these ductile iron DIN F5 resilient seated rising stem flanged gate valves provide a secure and leak-proof connection with the piping system. The flanged design allows those DIN F5 gate valves for easy and efficient installation, reducing downtime during system setup or maintenance. The ability to quickly bolt the valve to the piping system ensures a seamless integration that contributes to overall plumbing efficiency.

5. Precise Flow Control and Backflow Prevention:

Ductile iron DIN F5 EPDM lined resilient seated rising stem flanged gate valves offer precise flow control capabilities, allowing users to regulate fluid movement effectively. Additionally, the valve’s design provides inherent backflow prevention, preventing the reverse flow of fluids and maintaining the integrity of the plumbing system. This feature ensures safety and prevents cross-contamination.

where is ductile iron DIN F5 EPDM lined resilient seated rising stem flanged gate valve commonly used?

Ductile iron DIN F5 EPDM lined resilient seated rising stem flanged gate valves are commonly used in various industries and applications where reliable flow control and longevity are critical. Here are some common applications where these gate valves find frequent usage:

Water Treatment Plants: These DIN F5 resilient seated rising stem flanged gate valves are widely employed in water treatment facilities for controlling the flow and isolation of water in pipelines. Their durability, corrosion resistance, and precise flow control make them suitable for handling large volumes of water in both municipal and industrial water treatment processes.

Irrigation Systems: In agricultural irrigation systems, ductile iron EPDM lined resilient seated rising stem flanged gate valves play a significant role in regulating water flow to different sections of the fields. They assist in optimum water distribution, ensuring proper hydration for crops and preventing water wastage.

Power Generation: DIN F5 flanged Gate valves are essential components in power plants for controlling the flow of steam, condensate, and other fluids. The ductile iron construction with EPDM lining and rising stem design makes them highly suitable for withstanding high temperatures and pressure conditions commonly found in steam power generation facilities.

HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize those DIN F5 resilient seated flanged gate valves ductile iron body to regulate the flow of liquids or gases throughout various sections of the system. These gate valves facilitate efficient heat transfer, optimize energy consumption, and provide precise control in HVAC applications.

Chemical and Petrochemical Industries: Ductile iron DIN F5 EPDM lined resilient seated rising stem flanged gate valves are commonly employed in chemical and petrochemical processing plants. They offer excellent resistance to corrosive chemicals and can withstand harsh operating conditions, making them suitable for handling various types of corrosive fluids.

Oil and Gas Pipelines: ductile iron DIN F5 EPDM lined flanged Gate valves are crucial components in oil and gas transmission pipelines for isolation and flow control. The ductile iron construction ensures robustness and longevity, making them ideal for handling the demanding conditions of the oil and gas industry.

It is important to note that the specific usage of ductile iron DIN F5 EPDM lined resilient seated rising stem flanged gate valves may vary based on the requirements and regulations of each industry and application.

There are various industrial valves apart from gate valves, like butterfly valves, check valves, ball valves, globe valves, even for the gate valves, there are various kinds of gate valves, like for different body materials, there are cast iron gate valves, ductile iron gate valves, WCB gate valves, stainless steel gate valves, for different design standard, there are GB gate valves, ANSI/API gate valves, DIN F4 gate valves, DIN F5 gate valves, BS5163 gate valves, AWWA water gate valves, JIS gate valves, KS gate valves, etc… so if you have no idea which kind of gate valves you should select, please contact our sales: