Forged stainless steel ball valve butt weld PN 63 is one type of industrial ball valve which is commonly used in industrial applications, particularly in pipelines and systems that handle corrosive or high-pressure fluids. These forged stainless steel ball valves butt welded PN63 are made from forged stainless steel, which offers excellent resistance to corrosion and high temperatures.

The term “butt welded” refers to the method of joining that forged ball valve PN63 to the pipeline or system. In this case, the forged stainless steel ball valve PN63 is welded directly to the pipe or fitting using a butt weld connection. This type of connection provides a strong and leak-proof joint, making it suitable for demanding applications.

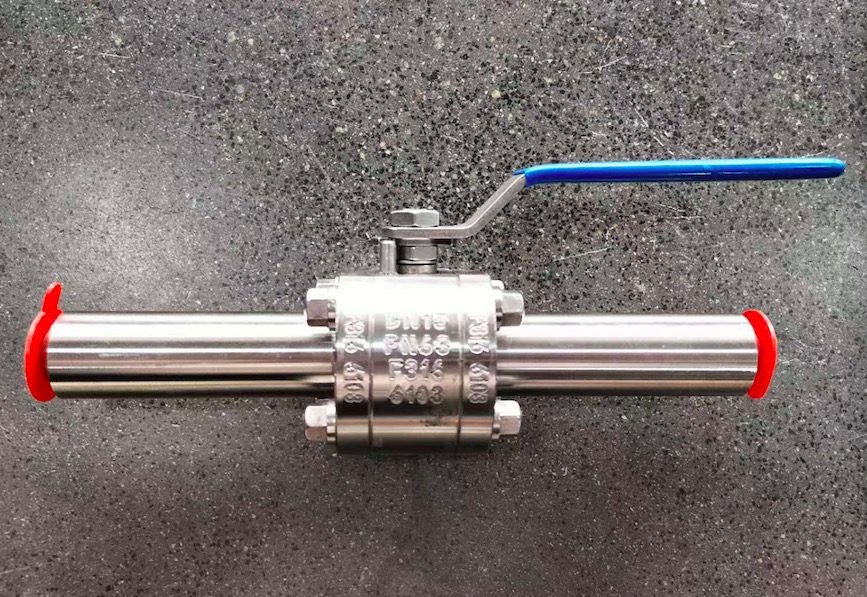

How forged stainless steel ball valve butt welded PN63 looks like:

Forged stainless steel ball valves butt welded PN63 have a ball-shaped disc inside the valve body that controls the flow of fluids. When the forged ball valve is open, the ball is rotated to allow fluid to pass through the forged ball valve butt welded freely. When the forged ball valve is closed, the ball is rotated to block the flow of fluid completely.

Main components for forged stainless steel ball valve butt welded PN63:

These 3pc forged stainless steel ball valves butt welded PN63 reduced bore are designed to withstand high pressures and temperatures, making them suitable for various industries such as oil and gas, chemical processing, power generation, and water treatment. They are commonly used in applications where reliable and efficient fluid control is essential.

It’s important to note that specific details about 3pc forged stainless steel ball valve butt weld reduced bore PN63, such as design standards, pressure ratings, and dimensions, may vary depending on the manufacturer and specific application requirements. If you need more detailed information, please contact our sales for price, more technical specifications.

Key Features of 3pc forged stainless steel reduced bore ball valve butt welded PN63:

1. Material: 3 pc Forged stainless steel ball valves butt welded PN63 are made from high-quality stainless steel like stainless steel 316, etc , which offers excellent resistance to corrosion, chemicals, and extreme temperatures. This ensures long-lasting performance and minimal maintenance requirements.

2. Butt Welded End: The butt welded end design of that forged ss ball valve PN63 provides a secure and leak-proof connection. It involves welding the valve directly to the pipeline, eliminating the need for additional fittings or adapters. This results in a compact and streamlined installation, reducing the risk of potential leaks.

3. reduced Bore Design: These forged stainless steel ball valves PN63 typically feature a reduced bore design, allowing for unrestricted flow and minimal pressure drop. This ensures efficient operation and optimal performance in various fluid control applications.

Advantages of 3 pc forged stainless steel ball valve butt welded reduced bore PN63 :

1. Enhanced Durability: The forged stainless steel construction of these 3 pc ball valves PN63 ensures exceptional strength and durability, making them suitable for demanding environments and applications. They can withstand high pressures, extreme temperatures, and corrosive substances without compromising performance.

2. Reliable Sealing: The butt welded end design of that forged stainless steel 3pc ball valve PN63 reduced bore provides a reliable and leak-free sealing mechanism. The welded connection eliminates potential leak points, ensuring a secure and tight seal even under high-pressure conditions.

3. Easy Maintenance: Due to their robust construction and minimal number of components, 3 pc forged stainless steel ball valves with butt welded end reduced bore PN63 require minimal maintenance. This reduces downtime and associated costs, making them a cost-effective choice for various industries.

water pressure testing for 3pc forged stainless steel ball valve reduced bore butt welded PN63: