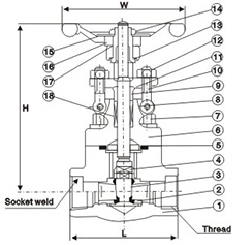

Forged Steel Internal Threaded Socket Gate Valve

Brief introduction:

The opening and closing part of Z61H forged steel gate valve is the valve disc. The movement direction of the disc is perpendicular to the direction of the fluid. That gate valve can only be fully opened and fully closed, and cannot be used to adjust the flow or throttle; there are two sealing surface on the disc, for the most used gate valves, that two sealing surfaces form a wedge, and the wedge angle degree varies with the valve parameters, usually its 50, and 2°52′ when the medium temperature is not too high.

12 month warranty!!

- Strict inspections before delivery !

- Direct factory price !

- Fast delivery !

Product Name:Forged Steel Internal Threaded Socket Gate Valve

Model No.:Z61H-1500LB

Brief introduction:

The opening and closing part of Z61H forged steel gate valve is the valve disc. The movement direction of the disc is perpendicular to the direction of the fluid. That gate valve can only be fully opened and fully closed, and cannot be used to adjust the flow or throttle; there are two sealing surface on the disc, for the most used gate valves, that two sealing surfaces form a wedge, and the wedge angle degree varies with the valve parameters, usually its 50, and 2°52′ when the medium temperature is not too high.

Characteristics:

1. Small flow resistance, the sealing surface is less washed and eroded by the medium.

2. Energy saving for opening and closing.

3. The flow direction of the medium is not restricted, without disturbing the flow and reducing the pressure.

4. Simple shape, short face to face length, good manufacturing technology, wide application.

Applications:

This gate valve can be widely used in tap water, sewage, construction, petroleum, chemical industry, food, medicine, textile, electric power, shipbuilding, metallurgy, energy and other industrial pipelines to adjust and cut off the mediums.

Standard:

| Design and manufacturing | Face to face | Flange connect | Test and inspection |

| API602 | ANSI B16.10 | ANSI B16.5 | API598 |

Technical Specifications:

| Model No. | PN(LB) | Test Pressure(LB) | Mediums | Working Temperature | |

| Strength(water) | Sealing(water) | ||||

| Z61H-1500LB | 1500 | 2250 | 1650 | Water,petroleum,gas | -29℃-450℃ |

| Z61H-800LB | 800 | 1200 | 880 | ||

| Z61H-900LB | 900 | 1350 | 990 | ||

| Z61H-800LB | 800 | 1250 | 880 | ||

| Z61H-600LB | 600 | 900 900 | 660 | ||

| Z61H-300LB | 300 | 450 | 330 | ||

| Z61H-150LB | 150 | 225 | 165 | ||

Parts Materials:

| No. | Part Name | Material |

| 1 | Body | A105N |

| 2 | Seat | A276 420 |

| 3 | Disc | A182 F430 |

| 4 | Stem | A182 F6a |

| 5 | Gasket | 304+Flexible Graphite |

| 6 | Bonnet | A105N |

| 7 | Bonnet Bolt | A193 B7 |

| 8 | Round Pin | A276 420 |

| 9 | Packing Pressure Plate | A276 410 |

| 10 | Eyelet Bolt | A193 B7 |

| 11 | Packing Pressure Sleeve | WCB |

| 12 | Nut | A194 2H |

| 13 | Stem Nut | A276 420 |

| 14 | Lock nut | A194 2H |

| 15 | Nameplate | SS |

| 16 | Hand wheel | HT200 |

| 17 | Lubricating Gasket | A473 431 |

| 18 | Packing | Flexible Graphite+Carbon Fiber |

Outline dimensions and connect dimensions

| Specifications | S | L | T(NPT) | W | H(open) | |||

| Reduced Port (RP) | Full Port (FP) | API Reduced port | API full port | Reduced port RP | Full port FP | |||

| 3/8 | 17.6 | 79 | 3/8 | 100 | 166 | |||

| 1/2 | 3/8 | 21.8 | 17.6 | 79 | 1/2 | 3/8 | 100 | 166 |

| 3/4 | 1/2 | 27.1 | 21.8 | 92 | 3/4 | 1/2 | 100 | 169 |

| 1 | 3/4 | 33.8 | 27.1 | 111 | 1 | 3/4 | 125 | 193 |

| 1 1/4 | 1 | 42.6 | 33.8 | 120 | 1 1/4 | 1 | 160 | 236 |

| 1 1/2 | 1 1/4 | 48.7 | 42.6 | 120 | 1 1/2 | 1 1/4 | 160 | 246 |

| 2 | 1 1/2 | 61.1 | 48.7 | 140 | 2 | 1 1/2 | 180 | 283 |

| 2 | 61.1 | 178 | 2 | 200 | 330 | |||

| DN | 3/8"-2" |

|---|---|

| PN | 150LB-1500LB |

| Mediums | Water,petroleum,gas |

| working temperature | -29℃~450℃ |