Butterfly valve is widely used in various industrial pipelines to connect, open and close the medium flow, which includes valve body,valve disc, valve seat, bushing, O type sealing ring, valve stem, connect bolts and nuts, pin, and actuating device( line lever handle, worm gear box, electric actuator, pneumatic actuator. According to different structure, butterfly valve is divided into center line butterfly valve(concentric butterfly valve), eccentric butterfly valve(offset butterfly valve)( which includes single eccentric butterfly valve, double eccentric butterfly valve, triple eccentric butterfly valve). According to end connect, butterfly valve has wafer type butterfly valve and flange type butterfly valve. According to different actuating device, we have manual lever handle butterfly valve, electric butterfly valve, pneumatic butterfly valve, butterfly valve with worm gear box. According to different material, there are ductile cast iron butterfly valve, stainless steel butterfly valve, WCB butterfly valve. According to different sealing material used, there are soft sealing butterfly valve(rubber lined soft sealing butterfly valve, PTFE lined soft sealing butterfly valve) and metal hard sealing butterfly valve. Today we are gonna talk about what is wafer type butterfly valve?

Belo Valve is a more than 15 years professional manufacturer for industrial valves, like butterfly valves( center line wafer butterfly valve, manual butterfly valve, lever driving butterfly valve, butterfly valve with worm gear box, lug type butterfly valve, soft seal butterfly valves, hard seal butterfly valves, flange butterfly valves, ductile cast iron butterfly valves, stainless steel butterfly valve), gate valves(including DINF4 gate valves, DINF5 gate valves, DIN3352 gate valves, rising stem gate valves, non rising stem gate valves, soft seal gate valves, hard seal gate valves, hydraulic gate valves, sluice valves), globe valves( DIN globe valves, bellows globe valves, electric globe valve), ball valves( welded ball valves, soft seal ball valves, stainless steel ball valves, WCB ball valves, ductile cast iron ball valves, API ball valves), check valves( wafer type check valves, swing check valves, rubber disc check valves, ball type check valve, foot valve/bottom valve), fire protection valves( grooved butterfly valves, grooved gate valves, grooved strainers, grooved check valves), hydraulic control valves,etc.

The definition of wafer type butterfly valve

The disc of the wafer type butterfly valve is installed in the diameter direction of the pipeline. In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis, and the rotation angle is between 0°-90°, when it rotates to 90°, the butterfly valve is fully open. This wafer type butterfly valve is generally installed horizontally. The wafer butterfly valve is simple in structure, small in size and light in weight, and only consists of a few components. It only needs to rotate 90° to open and close quickly, the operation is simple, and the wafer type butterfly valve has good fluid control characteristics. When the wafer butterfly valve is in the fully open position, the thickness of the butterfly plate is the only resistance when the medium flows through the valve body, so the pressure drop generated by the wafer type butterfly valve is very small. So wafer butterfly valve has better flow control characteristics. Wafer butterfly valve has two kinds of sealing materials: one is resilient sealing material(which is rubber, or PTFE), the other is metal hard sealing material. For resilient sealing wafer butterfly valve, the elastic sealing ring can be inlaid on the valve body or attached to the periphery of the disc.

Wafer type butterfly valve and flange type butterfly valve are two common used types of butterfly valves. But in structure, they have some difference: the wafer type butterfly valve uses stud bolts to connect the butterfly valve between the two pipeline flanges. The flange type butterfly valve has two flanges on its own valve body, the flanges at both ends of the flange butterfly valve are connected to the pipeline flanges with bolts.

Application of wafer type butterfly valve:

Wafer type butterfly valve is used for gas pipelines in the sulfuric acid industry: wafer butterfly valve can be installed in the inlet and outlet of the blower in front of the furnace, the inlet and outlet of the relay fan, the series and connecting valves of the electric demister, the inlet and outlet of the SO2 main blower, the adjustment of the converter, the inlet and outlet of the preheater,etc. Wafer butterfly valve is used for sulfur incineration conversion and dry suction in the sulfuric acid system. Wafer type butterfly valve is the preferred brand of valves for sulfuric acid plants. Wafer type butterfly valve is considered by majority of customers as good sealing performance, light operation, secondary corrosion, high temperature resistance, convenient operation, flexible, safe and reliable wafer butterfly valves have been widely used.

Wafer type butterfly valve is also used in: SO2, steam, air, gas, ammonia, CO2 gas, oils, water, brine, lye, seawater, nitric acid, hydrochloric acid, sulfuric acid, phosphoric acid in chemical, petrochemical, smelting, pharmaceutical, food and other industries. Wafer type butterfly valve is used as a regulating and shut-off device on pipelines.

Advantages of wafer type butterfly valve:

① the unique design of wafer butterfly valve enables friction-less transmission between the sealing surfaces, which extends the service life of the wafer butterfly valve.

② A resilient seal is produced by torque;

③ the ingenious wedge-shaped design enables the wafer butterfly valve to have an automatic sealing function of closing and tightening, with compensation and zero leakage between the sealing surface;

④ the wafer type butterfly valve has small size, light weight, and is light to operate and easy to install.

⑤pneumatic, electric, hydraulic and manual actuating devices can be equipped according to the customer’s requirements to meet the needs of remote control and program control;

⑥ with different material used for valve items, wafer type butterfly valve can be used for various mediums, and wafer type butterfly valve can be lined with anti-corrosion material(lined with F46, GXPP, PO,etc).

⑦ butterfly valve has various continuous structures: wafer type butterfly valve, flange type butterfly valve, and butt welding type butterfly valve;

Installation of wafer type butterfly valve:

1. preparation before installation of wafer butterfly valve:

① before installation, check whether the specifications and materials of the wafer type butterfly valve confirm to the design requirements;

② before installation, clean up the internal sand, foreign matters and debris to avoid malfunction or leakage;

③ before installation, the relevant piping should be properly suspended and fixed according to regulations to avoid improper stress on the wafer butterfly valve after installation;

④ the two flange faces of the piping must be parallel and concentric;

⑤ there is no need to add a gasket between the wafer type butterfly valve and the flanges during installation;

2. Installation steps for wafer type butterfly valve:

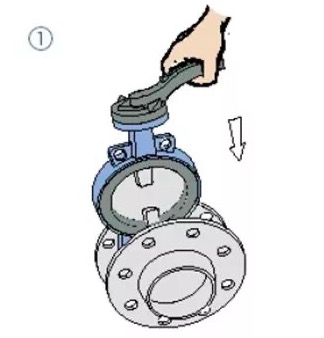

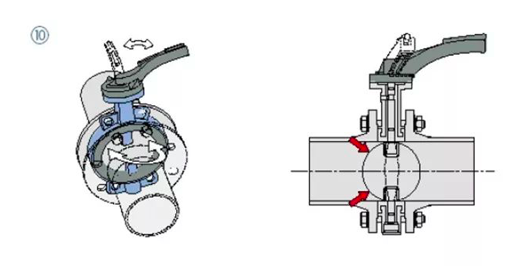

① open the valve disc 10° before installation of the wafer type butterfly valve;

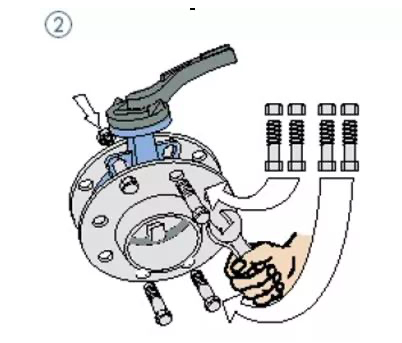

② set auxiliary screws at appropriate positions to adjust the distance between the two flange faces;

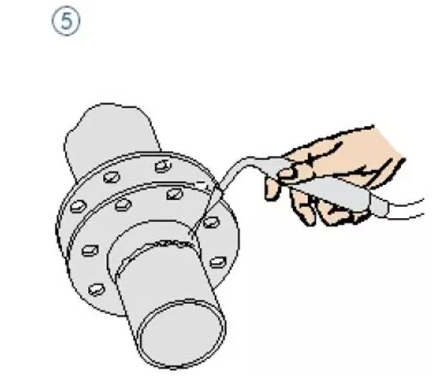

③ insert the wafer type butterfly valve without touching the two flange faces while threading the remaining bolts;

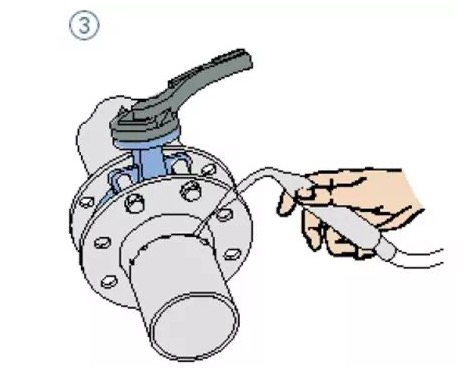

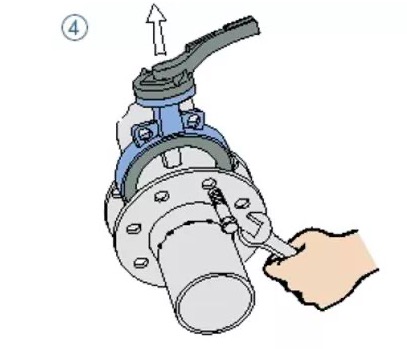

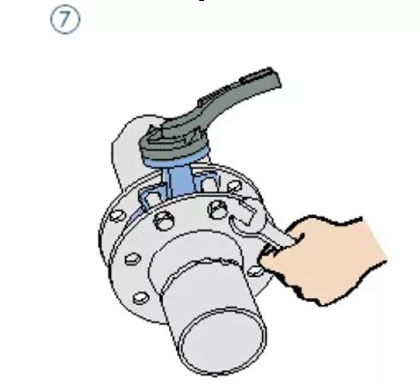

④ after confirming that the center of the butterfly valve is concentric with the center of the flange and the valve disc opening and closing position is not obstructed by the inner diameter of the flange or adjacent parts, lock the bolts repeatedly in a diagonal progressive manner until the flange face touches the end face of the valve body.

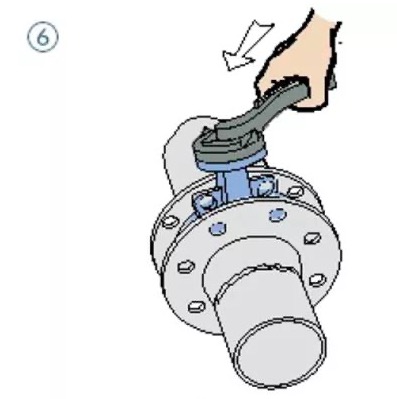

⑤ after the installation is completed, the fully open and fully closed degrees should be reconfirmed;

How to operate the wafer type butterfly valve:

① before starting the operation, use air spray to remove foreign objects on the piping, and clean the inner surface of the piping with clean water;

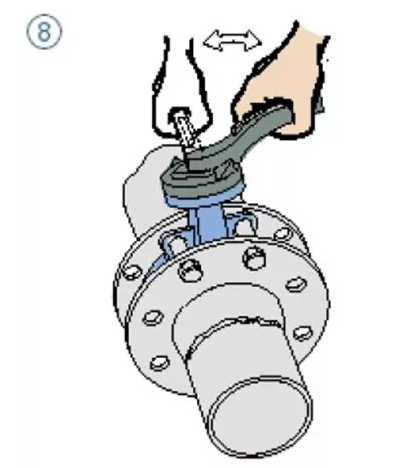

② open the butterfly valve to view the angle indicator disc and avoid twisting beyond the opening width and closing position;

③ the operation of the switch is completely based on the indicator. If other hand tools are used to exert force, the angle indicator plate and the switch will be damaged;

④ to do the piping pressure test, open the butterfly valve;

⑤ after piping, the wafer butterfly valve is in a fully closed state for a long time, and the opening and closing action should be done 1-2 times a month to avoid sticking;