Knife gate valve, is also called knife type gate valve, is one kind of special gate valve. Known from its name, the knife gate valve has one knife-shaped plate at the bottom of the valve body, which can cut off the mediums sharply, so that the knife gate valve can be closed without being blocked by the medium.

Knife type gate valve is generally used for the opening and closing of mediums like pulp, coal ash, chemical raw material, sewage, food and other medias. The working pressure range of knife type gate valve is generally within 1.6Mpa, the general working temperature of knife gate valve is below 120℃, and knife type gate valve can also be used for high temperature conditions if special materials are used for valve body, valve shaft, valve plate, and sealing part.

The knife type gate valve has the remarkable advantages like light for switching, reliable sealing, great elastic memory and long service life. Knife gate valve can be used widely in tap water, sewage, construction, petroleum, chemical industry, food, medicine, textile, electric power, shipbuilding, metallurgy, energy system. Knife type gate valve is mainly used as the cutting-off device.

Types of knife gate valve:

With different body material used, there are stainless steel knife gate valve, ductile iron knife gate valve, Carbon steel/WCB knife gate valve.

With different sealing material used, there are metal to metal seated knife gate valve, soft sealing knife gate valve.

With different end connection, there are wafer type knife gate valve, wafer lugged knife gate valve, flange end knife gate valve.

Today we are going to introduce you the ANSI GGG40 Ductile iron bidirectional wafer type knife gate valve:

Body material: GGG40/ductile iron

Disc material: stainless steel 304.

Valve seat: Natural Rubber.

Bottom plate material: Q235(ductile iron).

Valve shaft: 2Cr13(SS420)

Packing: EPDM/PTFE

Yoke: GGG40.

Operation: Hand-wheel

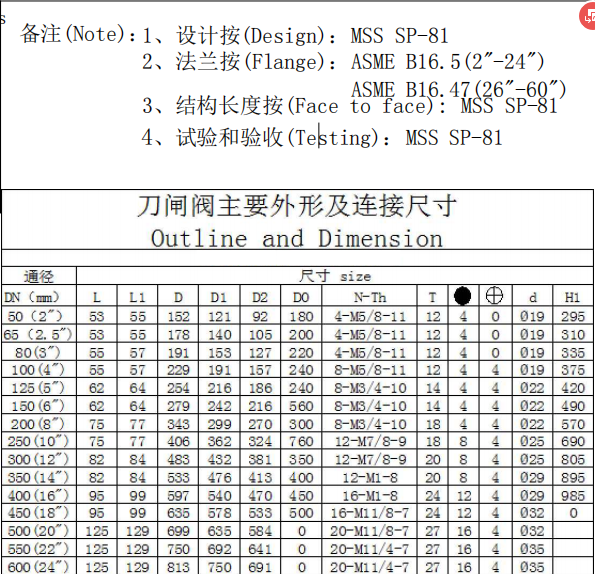

Design standard: MSS SP-81

Flange standard: ASME B16.5

Face to Face standard: MSS SP-81

DN: 2″-24″(DN50mm-DN600mm)

PN: 150LB

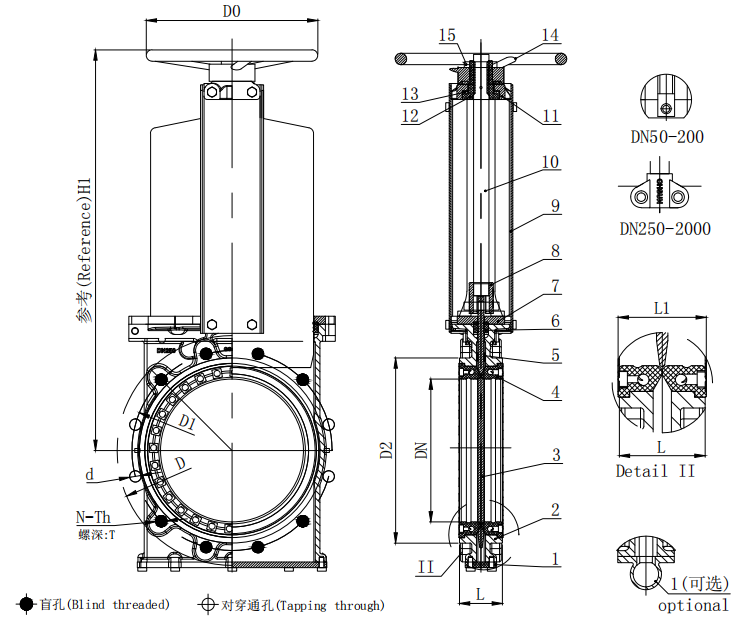

Main components: valve body, valve plate, valve shaft, bottom plate, valve seat, yoke, operating device, etc.

Applicable Mediums: pulp, sewage, coal slurry, ash, slag water mixture.

Keywords: knife type gate valve, ANSI GGG40 wafer knife gate valve, ductile iron bidirectional knife gate valve, soft sealing wafer knife gate valve, GGG40 soft sealing knife type gate valve.

Advantages of knife gate valve:

1. The knife type gate valve has ultra-short structural length, which can save the manufacturing material, and reduce the overall weight of the piping system.

2. The knife type gate valve only occupies a small effective space, can effectively support the strength of the pipeline, and can reduce the possibility of pipeline vibration.

3. The valve plate of the knife type gate valve is made of austenitic stainless steel, which greatly improves the corrosion resistance of the knife gate valve, and can effectively prevent the sealing leakage caused by the corrosion of the valve plate of the knife gate valve.

4. The upper sealing packing of the knife type gate valve is made of flexible PTFE, which has reliable sealing effect and easy to operate.

5. The plate of the knife gate valve has the function of a knife which can effectively break off all kinds of sundries in the medium.

6. If the sealing material of the knife type gate valve can be made of stainless steel, and the valve plate of the knife gate valve can be spray-welded, the metal to metal seated knife type gate valves can be used for high pressure and temperatures.

Details for ANSI GGG40 DI bidirectional wafer type knife gate valve:

Package details for ANSI GGG40 DI bidirectional wafer type knife gate valve:

for more details about that ANSI GGG40 DI bidirectional wafer type NR soft sealing knife gate valve, kindly contact us: