Industrial valve is one important device for pipeline systems to control the opening and closing of the media flow. with different design, industrial valves can be divided into industrial butterfly valves, industrial gate valves, industrial globe valves, industrial check valve(also knowns as industrial non return valve), industrial ball valves, safety valves, etc. today we are going to introduce some information about some kind of butterfly valves, which belongs to concentric butterfly valves, whose sealing structure is using the resilient rubber material to realize zero leakage. and also because of the simple structural design, the manufacturing cost of resilient seated concentric butterfly valves is relatively lower than that of other industrial valves. that is why those resilient seated soft sealing concentric butterfly valves are widely used for water pipeline systems.

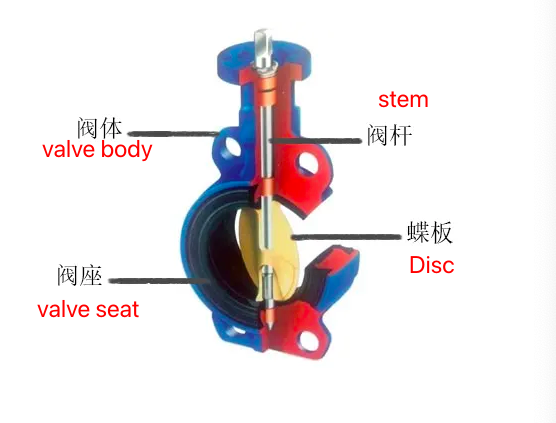

How ductile iron concentric wafer type resilient seated butterfly valve looks like:

Simple introduction of ductile iron concentric wafer type resilient seated butterfly valve?

The ductile iron concentric wafer type resilient seated butterfly valve is a reliable and high-performance industrial valve designed for various applications in industries such as water treatment, chemical processing, power generation, and HVAC systems. This valve provides a cost-effective solution for regulating and controlling the flow of fluids in pipelines.

The main components of ductile iron concentric wafer type resilient seated butterfly valve are valve body, valve shaft, valve plate, valve seat, and operator, the valve plate rotates 90℃ around the valve shaft to realize the opening and closing of the butterfly valve. Belo Valve is one professional wholesaler, exporter for concentric butterfly valves, with diameter range DN50-DN1200, PN10-PN16. the body material options for concentric wafer type resilient seated butterfly valve can be cast iron, ductile iron, WCB(carbon steel) or stainless steel, or some special alloy material according to customer’s requirements. and the sealing material of concentric wafer type resilient seated butterfly valve can be EPDM, NBR, PTFE. and the plate material of concentric wafer type resilient seated butterfly valve can be ductile iron or stainless steel. and for the operator of concentric wafer type resilient seated butterfly valve can be hand lever, worm gear box, electric actuator, pneumatic actuator.

Belo Valve can meet your requirements about various concentric butterfly valves, we can supply concentric wafer type butterfly valves, concentric lugged butterfly valves, concentric flanged butterfly valves. with body material cast iron, ductile iron, stainless steel and carbon steel(WCB). especial for some large diameter concentric flanged butterfly valves, our manufacturing processing is very professional now.

Specifications of ductile iron concentric wafer type resilient seated butterfly valve:

– Size range: ductile iron concentric wafer type resilient seated butterfly valve is Available in sizes ranging from DN50mm to DN1200mm, ensuring compatibility with different piping systems.

– Pressure rating: ductile iron concentric wafer type resilient seated butterfly valve is designed to handle pressures up to 2.5mpa, making it suitable for both low and medium-pressure applications.

– Temperature range: ductile iron concentric wafer type resilient seated butterfly valve is capable of functioning in temperatures ranging from -10°C to 120°C, offering versatility for various operating conditions.

– End connections: ductile iron concentric wafer type resilient seated butterfly valves are equipped with wafer end, lug style end and flanged end, allowing the butterfly valve to fit snugly between two mating flanges without the need for additional bolts.

– Design standards: ductile iron concentric wafer type resilient seated butterfly valve is manufactured in compliance with international standards such as API 609 and EN 593, ensuring product quality and performance.

Material options of ductile iron concentric wafer type resilient seated butterfly valve:

The ductile iron concentric wafer type resilient seated butterfly valve is constructed with high-quality materials to ensure durability and resistance to corrosion. The main materials used include:

– Body: the valve body of ductile iron concentric wafer type resilient seated butterfly valve is made from ductile iron (also known as spheroidal graphite iron), providing enhanced strength and flexibility compared to traditional cast iron.

– Plate/Disc: the valve plate of ductile iron concentric wafer type resilient seated butterfly valve is manufactured from ductile iron or stainless steel, depending on the application requirements. The disc design ensures optimal flow control and minimal pressure drop.

– Seat: the ductile iron concentric wafer type resilient seated butterfly valve is comprised of an EPDM (Ethylene Propylene Diene Monomer) , NBR (Nitrile Butadiene Rubber) or PTFE (Polytetrafluoroethylene) seat, providing excellent sealing properties and chemical resistance.

– Stem/Shaft: the stem/shaft of ductile iron concentric wafer type resilient seated butterfly valve is constructed from stainless steel, offering high mechanical strength and resistance to corrosion.

Where those ductile iron concentric wafer type resilient seated butterfly valves are used:

1. Water treatment: the ductile iron concentric wafer type resilient seated butterfly valve is used for controlling the flow of water in municipal water distribution systems, wastewater treatment plants, and desalination plants.

2. Chemical processing: the ductile iron concentric wafer type resilient seated butterfly valves are ideal for handling aggressive chemicals, acids, and alkalis in chemical processing plants, ensuring safe and efficient operation.

3. Power generation:the ductile iron concentric wafer type resilient seated butterfly valve can be installed in power plants for regulating the flow of water, steam, and gases throughout the system, contributing to the overall energy production process.

4. HVAC systems: the ductile iron concentric wafer type resilient seated butterfly valve can be employed in heating, ventilation, and air conditioning systems to maintain appropriate fluid flow, ensuring efficient cooling or heating in commercial and residential buildings.

5. General industry: the ductile iron concentric wafer type resilient seated butterfly valves are widely used in various industrial processes such as food and beverage, pharmaceuticals, and manufacturing, facilitating the controlled flow of fluids.

Why those ductile iron concentric wafer type resilient seated butterfly valves are widely used? now we are going to introduce the advantages of ductile iron concentric wafer type resilient seated butterfly valves:

1. Excellent flow control: The concentric disc design of the ductile iron concentric wafer type resilient seated butterfly valve can ensure precise flow control and minimal pressure drop across the valve, promoting energy efficiency in the system.

2. Bubble-tight seal: The resilient seat of the ductile iron concentric wafer type resilient seated butterfly valve is made of EPDM or NBR, which offers a tight seal to prevent leakage, reducing the risk of product loss or contamination, can realize the zero leakage.

3. Bi-directional operation: The ductile iron concentric wafer type resilient seated butterfly valve can be installed in either direction, providing flexibility during installation and ensuring optimal performance.

4. Low maintenance: The robust construction and high-quality materials used in this ductile iron concentric wafer type resilient seated butterfly valve result in minimal maintenance requirements, reducing downtime and overall costs.

5. Easy installation: The wafer-style end connect of ductile iron concentric wafer type resilient seated butterfly valve simplify installation as they require fewer bolts compared to traditional flanged valves, saving time and effort.

6. Versatility: ductile iron concentric wafer type resilient seated butterfly valves are suitable for both on/off and throttling applications, this valve can be used in systems requiring isolation or regulation of fluid flow.

In conclusion, the ductile iron concentric wafer type resilient seated butterfly valve is a reliable and versatile industrial valve suitable for various industries. It offers excellent flow control, tight sealing, and low maintenance, making it a cost-effective choice for regulating fluid flow in pipelines. Its high-quality construction and compliance with international standards ensure durability and performance in diverse operating conditions.