cast iron GG25 DIN flanged Y type strainer

Brief introduction of cast iron GG25 DIN flanged Y type strainer/flange end Y type filter:

Cast iron GG25 DIN flanged Y type strainer/flange end Y type filter is a type of strainer or filter used in industrial applications to remove impurities from pipelines. It is made of cast iron GG25, which is a type of gray iron known for its strength and durability.The Y type design of that cast iron GG25 DIN flanged strainer/filter allows for efficient filtering of debris and solids from the fluid flow. The flange end of the DIN cast iron strainer/DIN flanged filter ensures easy installation and connection to the pipeline system. That cast iron GG25 DIN Y type strainer/filter is designed according to DIN standards, ensuring compatibility and reliability.

12 month warranty!!

- Strict inspections before delivery !

- Direct factory price !

- Fast delivery !

Product Name:cast iron GG25 DIN flanged Y type strainer/flanged Y type filter

Model No.: GL41H-16

Brief introduction of cast iron GG25 DIN flanged Y type strainer/flange end Y type filter:

Cast iron GG25 DIN flanged Y type strainer/flange end Y type filter is a type of strainer or filter used in industrial applications to remove impurities from pipelines. It is made of cast iron GG25, which is a type of gray iron known for its strength and durability.The Y type design of that cast iron GG25 DIN flanged strainer/filter allows for efficient filtering of debris and solids from the fluid flow. The flange end of the DIN cast iron strainer/DIN flanged filter ensures easy installation and connection to the pipeline system. That cast iron GG25 DIN Y type strainer/filter is designed according to DIN standards, ensuring compatibility and reliability.

How that cast iron GG25 DIN flanged Y type strainer/flange end Y type filter works:

The cast iron GG25 DIN flanged Y type strainer/flange end Y type filter works by utilizing a Y-shaped straining element to remove impurities from the fluid flowing through the pipeline. Here is a brief overview of how it works:

1. Fluid Flow: The fluid enters the cast iron GG25 DIN flanged Y type strainer/filter through the inlet flange end. The flange end ensures a secure connection to the pipeline system.

2. Y-Shaped Strainer Element: Inside the DIN Y type strainer/filter, there is a Y-shaped strainer element. This element is designed with a perforated screen or mesh that captures solid particles and debris present in the fluid.

3. Filtration Process: As the fluid flows through the cast iron DIN flanged Y type strainer/filter, the flanged Y-shaped strainer element directs the flow towards the straining surface. The perforations or mesh on the strainer element trap the impurities, preventing them from passing through.

4. Clean Fluid Outlet: The filtered fluid then passes through the strainer element and exits the DIN Y type flanged strainer/filter through the outlet. The cleaned fluid can continue its journey through the pipeline system, free from contaminants.

5. Maintenance and Cleaning: Over time, the strainer element may accumulate a significant amount of debris. Periodic maintenance and cleaning are required to remove the trapped particles and ensure the DIN Y type strainer/filter’s optimal performance. This typically involves removing the strainer element, cleaning it, and reinstalling it.

Overall, the cast iron GG25 DIN flanged Y type strainer/flange end Y type filter effectively separates solid particles and debris from the fluid flow, protecting downstream equipment and processes from potential damage or clogging.

What are those key advantages of cast iron GG25 DIN flanged Y type strainer/flange end Y type filter:

That cast iron GG25 DIN flanged Y type strainer/flange end Y type filter offers several advantages that make it a preferred choice in industrial applications. Here are the main advantages:

1. Durability: Cast iron GG25 used as the body and bonnet material of DIN Y type flanged strainer/DIN Y type flanged filter is known for its excellent strength and durability. It can withstand high pressures and temperatures, making the strainer/filter suitable for demanding industrial environments.

2. Efficient Filtration: The Y type design of that cast iron GG25 Y shaped strainer/flanged y type filter allows for efficient filtration of debris and solid particles from the fluid flow. The Y-shaped strainer element effectively traps impurities, preventing them from passing through and causing damage to downstream equipment.

3. Easy Installation: The flange end design of that DIN Y type strainer/Y type filter ensures easy installation and connection to the pipeline system. The flanges provide a secure and leak-proof connection, saving time and effort during installation.

4. Compatibility: That cast iron GG25 DIN Y type strainer/filter is designed according to DIN standards, ensuring compatibility with existing pipeline systems and components. This allows for seamless integration into industrial processes without the need for extensive modifications.

5. Protection of Equipment: By removing impurities from the fluid flow, that cast iron DIN Y type strainer/flanged Y type filter helps to protect downstream equipment such as pumps, valves, and meters. It prevents clogging, damage, and premature wear, thereby extending the lifespan of equipment and reducing maintenance costs.

6. Versatility: The cast iron GG25 DIN flanged Y type strainer/flange end Y type filter is suitable for various industries, including oil and gas, chemical, water treatment, and manufacturing. It can handle a wide range of fluids, making it a versatile solution for different applications.

Overall, the main advantages of the cast iron GG25 DIN flanged Y type strainer/flange end Y type filter include its durability, efficient filtration, ease of installation, compatibility, equipment protection, and versatility.

Main Applications of cast iron GG25 DIN flanged Y type strainer/flange end Y type filter:

The cast iron GG25 DIN flanged Y type strainer/flange end Y type filter finds applications in various industries where the removal of impurities from fluid flow is critical. Here are some of the main applications:

1. Oil and Gas: That cast iron GG25 DIN flanged Y type strainer/flange end Y type filter is commonly used in oil and gas pipelines to remove debris, sand, and other solid particles that can cause damage to downstream equipment such as pumps, industrial valves, and meters.

2. Chemical Industry: In chemical processing plants, those cast iron GG25 DIN flanged Y type strainers/flange end Y type filters are utilized to protect sensitive equipment, such as heat exchangers and spray nozzles, from clogging and damage caused by contaminants present in the process fluids.

3. Water Treatment: The cast iron GG25 DIN flanged Y type strainer/flange end Y type filter is employed in water treatment facilities to remove sediment, algae, and other particles from raw water sources. This helps maintain the efficiency of water treatment processes and ensures the delivery of clean, filtered water.

4. Manufacturing: In manufacturing industries, cast iron GG25 DIN flanged Y type strainer/flange end Y type filter is used to filter cooling water, lubricants, and other fluids used in various processes. It helps prevent blockages and damage to machinery, ensuring smooth operations and reducing downtime.

5. HVAC Systems: The cast iron GG25 DIN flanged Y type strainer/flange end Y type filter is utilized in heating, ventilation, and air conditioning (HVAC) systems to remove debris and contaminants from the circulating water or air. This helps maintain the efficiency of HVAC equipment and ensures clean, healthy air circulation.

6. Petrochemical Industry: In petrochemical plants, the cast iron GG25 DIN flanged Y type strainer/flange end Y type filter is employed to protect equipment, such as compressors and turbines, from damage caused by solid particles and impurities present in the process fluids.

These are just a few examples of the main applications of the cast iron GG25 DIN flanged Y type strainer/flange end Y type filter. Its versatility and effectiveness in removing impurities make it a crucial component in various industries where the cleanliness and efficiency of fluid flow are essential.

Standards applied for cast iron GG25 DIN flanged Y type strainer/flange end Y type filter:

Flange drilled standard: DIN2532/DIN2533/DIN2501

Face to face standard: DIN3202-F1.

Material for main components of cast iron GG25 DIN flanged Y type strainer/flange end Y type filter:

Body and bonnet: Gray cast iron(or called CI,GG25, cast iron) and ductile iron(called ductile cast iron/DI/GGG40).

Screen: stainless steel.

Plug: ductile iron.

Gasket: Graphite.

Bolts and nuts: carbon steel.

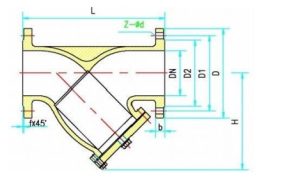

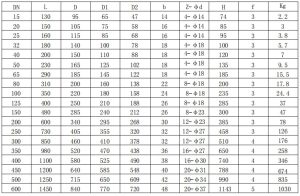

Outline dimensions and connect dimensions of cast iron GG25 DIN flanged Y type strainer/flange end Y type filter:

| DN | DN15-DN600 |

|---|---|

| PN | PN10 and PN16 |

| Media | water, steam, petroleum products, etc |

| working temperature | ≤200℃ |