cast iron GG25 DIN globe valve flanged type

Brief introduction of cast iron GG25 DIN globe valve flanged type:

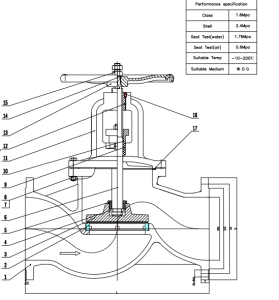

The cast iron GG25 DIN globe valve flanged type is a type of globe valve which is commonly used in piping systems for controlling the flow of fluids. That DIN flanged globe valve is made from GG25 cast iron material, which provides good strength and corrosion resistance. That DIN globe valve GG25 is designed with a flanged connection, making it easy to install and maintain.This cast iron GG25 flanged DIN globe valve is typically designed to withstand working pressures of PN10 and PN16, as per the DIN standard. It is suitable for a wide range of non-corrosive media such as water, steam, oil, and gases.

12 month warranty!!

- Strict inspections before delivery !

- Direct factory price !

- Fast delivery !

Product Name: cast iron GG25 DIN globe valve flanged type

Model No.: (DIN) J41H-16-150

Brief introduction of cast iron GG25 DIN globe valve flanged type:

The cast iron GG25 DIN globe valve flanged type is a type of globe valve which is commonly used in piping systems for controlling the flow of fluids. That DIN flanged globe valve is made from GG25 cast iron material, which provides good strength and corrosion resistance. That DIN globe valve GG25 is designed with a flanged connection, making it easy to install and maintain.This cast iron GG25 flanged DIN globe valve is typically designed to withstand working pressures of PN10 and PN16, as per the DIN standard. It is suitable for a wide range of non-corrosive media such as water, steam, oil, and gases.

What is the working principle of cast iron GG25 DIN globe valve flanged type:

The working principle of a cast iron GG25 flanged DIN globe valve is based on the movement of a disc or plug inside the valve body to control the flow of fluid.

When the DIN globe valve is in the closed position, the disc or plug is pressed against the seat, creating a tight seal and preventing the flow of fluid. When the cast iron flanged DIN globe valve is in the open position, the disc or plug is lifted away from the seat, allowing the fluid to flow through the valve.

The movement of the disc or plug is controlled by a stem, which is connected to a hand wheel or actuator. When the hand wheel or actuator is turned or activated, it rotates the stem, causing the disc or plug to move up or down.

The cast iron GG25 flanged DIN globe valve has a globe-shaped body, which helps to regulate the flow of fluid smoothly and evenly. The flanged ends of that GG25 DIN globe valve allow for easy installation and connection to the pipeline.

Overall, the working principle of the cast iron GG25 flanged DIN globe valve involves the movement of the disc or plug to control the flow of fluid, providing a reliable and efficient solution for regulating fluid flow in various applications.

Key advantages of cast iron GG25 DIN globe valve flanged type:

There are several key advantages of cast iron GG25 flanged type DIN globe valves:

Durability: Cast iron GG25 is a strong and durable material which can withstand high pressure and temperature conditions, making that flanged type din globe valves suitable for various industrial applications.

Corrosion resistance: Cast iron GG25 is highly resistant to corrosion, making that globe valve ideal for use in environments where the valve may come into contact with corrosive fluids or gases.

Versatility: Cast iron GG25 flanged type DIN globe valves are available in a wide range of sizes and pressure ratings, allowing them to be used in various piping systems and applications.

Easy maintenance: These cast iron GG25 flanged type DIN globe valves are designed for easy maintenance and repair, with replaceable components that can be easily accessed and replaced when needed.

Tight shut-off: Cast iron GG25 flanged type DIN globe valves can provide a tight shut-off, ensuring that there is minimal leakage when the DIN globe valve is closed, thereby preventing any loss of fluids or gases.

Good flow control: The GG25 din flanged globe valve design allows for precise flow control, making it suitable for applications where precise regulation of flow rate is required.

Cost-effective: Cast iron GG25 flanged type DIN globe valves are relatively affordable compared to other valve materials, making them a cost-effective choice for many industrial applications.

Main applications of cast iron GG25 flanged type DIN globe valve:

The main applications of cast iron GG25 flanged type DIN globe valves include:

Water supply and distribution systems: These cast iron GG25 flanged DIN globe valves are commonly used in water supply and distribution systems to regulate the flow of water. They are suitable for both potable and non-potable water applications.

HVAC systems: Cast iron GG25 flanged type DIN globe valves are widely used in heating, ventilation, and air conditioning (HVAC) systems to control the flow of hot or cold water, steam, or other fluids. They help in maintaining the desired temperature and pressure levels.

Industrial processes: These cast iron GG25 DIN globe valves gland sealing find applications in various industrial processes where the flow of fluids needs to be controlled. They are commonly used in industries such as chemical, petrochemical, pharmaceutical, and food processing.

Irrigation systems: Cast iron GG25 DIN globe valves flanged type are used in irrigation systems to regulate the flow of water to different sections of the irrigation network. They help in ensuring proper water distribution and preventing water wastage.

Fire protection systems: These flanged type DIN globe valves are also used in fire protection systems, such as fire hydrant systems and sprinkler systems, to control the flow of water during fire emergencies. They help in directing water to the required areas and extinguishing the fire.

Oil and gas industry: Cast iron GG25 flanged type DIN globe valves are used in the oil and gas industry for various applications, including pipeline systems, refineries, and storage tanks. They help in controlling the flow of oil, gas, and other fluids in these systems.

Waste and wastewater treatment: These GG25 cast iron DIN globe valves are used in waste and wastewater treatment plants to control the flow of liquids and gases during the treatment process. They help in managing the movement of fluids and maintaining the efficiency of the treatment systems.

Overall, cast iron GG25 flanged type DIN globe valves are versatile and widely used in various industries and applications where reliable flow control is required.

Standard of DIN globe valve gland sealing:

| Design and manufacturing | Face to face | Flange connect | Inspect and inspection |

| DIN3352 | DIN3202-F1 | DIN2532/2533/2501 | DIN3230 |

Technical specifications of GG25 DIN globe valve flanged type:

| Model No. | PN(MPa) | Test pressure(MPa) | medium | Working temperature | |

| Strength(water) | Seal(water) | ||||

| (DIN)J41H-10 | 1.0 | 1.5 | 1.1 | Water, oils | -10℃-200℃ |

| (DIN)J41H-16 | 1.6 | 2.4 | 1.8 | ||

Material for main parts of DIN globe valve flanged type:

| Parts name | Material |

| Body and deck | cast iron GG25/ductile cast iron GGG40 |

| Stem nut | brass |

| Stem | SS420 |

| Disc | Stainless steel |

| Hand-wheel | steel/ductile cast iron/cast iron |

Outline dimensions and connect dimensions of flanged DIN globe valve gland sealing:

| Model No. | DN(mm) | Dimension(mm) | ||||

| L | D | D1 | ||||

| DIN globe valve cast iron flanged type | 1.0/1.6MPa | 1.0MPa | 1.6MPa | 1.0MPa | 1.6MPa | |

| 15 | 130 | 95 | 95 | 65 | 65 | |

| 20 | 150 | 105 | 105 | 75 | 75 | |

| 25 | 160 | 115 | 115 | 85 | 85 | |

| 32 | 180 | 140 | 140 | 100 | 100 | |

| 40 | 200 | 150 | 150 | 110 | 110 | |

| 50 | 230 | 165 | 165 | 125 | 125 | |

| 65 | 290 | 185 | 185 | 145 | 145 | |

| 80 | 310 | 200 | 200 | 160 | 160 | |

| 100 | 350 | 220 | 220 | 180 | 180 | |

| 125 | 400 | 250 | 250 | 210 | 210 | |

| 150 | 480 | 285 | 285 | 240 | 240 | |

| 200 | 600 | 340 | 340 | 295 | 295 | |

| 250 | 720 | 395 | 405 | 350 | 355 | |

| 300 | 850 | 445 | 460 | 400 | 410 | |

| DN | DN15-DN300 |

|---|---|

| PN | PN10 and PN16 |

| Media | Water, oils |

| working temperature | -10℃-200℃ |