DIN F4 hard seal non-rising stem gate valve

Brief introduction:

Gate valve is one of the widely used industrial valves in fluid transport projects to cut off the mediums. Non-rising stem gate valve has compact structure, reasonable design, smooth passage, large flow coefficient,small flow resistance and simple structure. It is easy to maintain. The sealing surface is using the brass or the body material, which has the long service life. The packing material is flexible graphite, which has reliable sealing effect. And its flexible to operate.

12 month warranty!!

- Strict inspections before delivery !

- Direct factory price !

- Fast delivery !

Product name: DIN F4 hard seal metal seated non-rising stem gate valve

Model No.: (DIN F4 ) F4Z45T-16

Brief introduction of F4 metal seated hard seal non rising stem gate valve:

DIN F4 Hard seal non rising stem gate valve is one of the widely used industrial gate valve valves in fluid transport projects to cut off the mediums. Non-rising stem gate valve has compact structure, reasonable design, smooth passage, large flow coefficient,small flow resistance and simple structure. It is easy to maintain. The sealing surface is using the brass or the body material, which has the long service life. The packing material is flexible graphite, which has reliable sealing effect. And its flexible to operate.

Characteristics of F4 metal to metal seated hard seal non-rising stem gate valves:

1. compact structure, reasonable design, smooth passage, large flow coefficient, small flow resistance, simple structure, easy to maintain.

2. flexible graphite as packing material, it is reliable in sealing, light and flexible to operate.

3. The driving mode can be manual, electric, or gear transmission.

Applications of DIN F4 metal to metal seated hard-seal non-rising stem gate valve:

This kind of metal to metal seated hard seal gate valve non rising stem is widely used in the petroleum, chemical, pharmacy, electric power and other industries, and is used for opening and closing of pipelines of steam, water, and oils mediums.

1. Oil and gas industry: DIN F4 metal to metal seated hard seal non rising stem gate valves are commonly used in upstream, midstream, and downstream operations of the oil and gas industry. They can be found in pipelines, refineries, petrochemical plants, and storage facilities, where they provide efficient shut-off and isolation of fluid flow.

2. Water and wastewater treatment: These F4 metal to metal seated hard seal non rising stem gate valves are suitable for water distribution and wastewater treatment systems. They can be used in large water supply networks, irrigation systems, dams, and water treatment plants where they help control the flow of water and isolate sections of the system for maintenance or repairs.

3. Power generation: DIN F4 metal to metal seated hard seal Gate valves non rising stem with metal-to-metal seating are employed in power plants, including thermal power, nuclear power, and hydropower plants. They are used in applications such as steam lines, feedwater systems, cooling water systems, and boiler feed pumps.

4. Chemical and petrochemical industry: DIN F4 hard sealing gate valves NRS find application in chemical processing plants, pharmaceutical manufacturing, and petrochemical facilities. They are often used for controlling the flow of corrosive and abrasive fluids, as their metal-to-metal sealing design provides excellent resistance to wear and chemical attack.

5. Mining and minerals processing: In the mining industry, DIN F4 non rising stem wedge gate valves with metal-to-metal seating are used for handling abrasive materials, slurries, and various mining fluids. They help control the flow of minerals, ores, and tailings in processing plants and are essential for isolating sections of pipelines during maintenance.

Standard:

| Design and manufacturing | Face to face | Flange connect | Test and inspection |

| DIN3352 | DIN3202-F4/F5 | DIN2532/2533/2501 | DIN3230 |

Technical specifications:

| Model No. | PN(MPa) | Test pressure(MPa) | Medium | Working temperature | |

| Strength(water) | Seal(water) | ||||

| (DIN)F4Z45T-10 | 1.0 | 1.5 | 1.1 | Water, oils | -10℃-200℃ |

| (DIN)F4Z45T-16 | 1.6 | 2.4 | 1.8 | ||

Material for main parts of F4 metal to metal hard seal gate valve

| Parts Name | Material |

| Body and deck | Ductile iron/cast iron |

| Stem nut | brass |

| Stem | SS420 |

| disc | Ductile iron/cast iron |

| Hand-wheel | Ductile iron/cast iron |

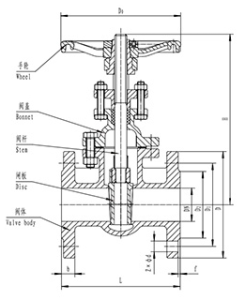

Outline dimensions and connect dimensions:

| Model No. | DN(mm) | Dimension(mm) | ||||

| L | D | D1 | ||||

| DIN F4 hard seal non-rising stem gate valve

|

1.0/1.6MPa | 1.0MPa | 1.6MPa | 1.0MPa | 1.6MPa | |

| 50 | 150 | 165 | 165 | 125 | 125 | |

| 65 | 170 | 185 | 185 | 145 | 145 | |

| 80 | 180 | 200 | 200 | 160 | 160 | |

| 100 | 190 | 220 | 220 | 180 | 180 | |

| 125 | 200 | 250 | 250 | 210 | 210 | |

| 150 | 210 | 285 | 285 | 240 | 240 | |

| 200 | 230 | 340 | 340 | 295 | 295 | |

| 250 | 250 | 395 | 405 | 350 | 355 | |

| 300 | 270 | 445 | 460 | 400 | 410 | |

| 350 | 290 | 505 | 520 | 460 | 470 | |

| 400 | 310 | 565 | 580 | 515 | 525 | |

| DN | 50-400 |

|---|---|

| PN | 10/16 |

| Mediums | water, steam, oils |

| working temperature | -10~120℃ |