wafer High performance double eccentric butterfly valve 150LB

Brief introduction of wafer high performance butterfly valve

High performance butterfly valve is also called high performance double eccentric/double offset butterfly valve, which has wafer high performance butterfly valve, lug high performance butterfly valve and flanged high performance butterfly valve. High performance butterfly valves are mainly applied for drainage in water plants, steel mills, power plants, chemical industries, water source projects, environmental construction and other industrial systems. High performance butterfly valves are especially suitable for water pipelines as the regulating and intercepting device. Compared with the general concentric butterfly valves, high performance double eccentric butterfly valve is more resistant to high pressure, has a longer life and good stability.

12 month warranty!!

- Strict inspections before delivery !

- Direct factory price !

- Fast delivery !

Product Name: wafer High performance double eccentric butterfly valve 150LB

Model No: HPBFV-150LB

Brief introduction of wafer high performance butterfly valve

High performance butterfly valve is also called high performance double eccentric/double offset butterfly valve, which has wafer high performance butterfly valve, lug high performance butterfly valve and flanged high performance butterfly valve. High performance butterfly valves are mainly applied for drainage in water plants, steel mills, power plants, chemical industries, water source projects, environmental construction and other industrial systems. High performance butterfly valves are especially suitable for water pipelines as the regulating and intercepting device. Compared with the general concentric butterfly valves, high performance double eccentric butterfly valve is more resistant to high pressure, has a longer life and good stability.

Main characteristics of wafer high performance butterfly valve:

- High performance butterfly valve has reasonable design, compact structure, is easy for assembly and disassembly, and easy for maintenance.

- The high performance butterfly valve adopts the double eccentric structure to reduce the friction of the sealing ring and extend the service life of the high performance butterfly valve.

- The high performance uses a unique dynamic load sealing PTFE valve seat design, which has good elasticity and high reliability. There is no need to add other O-ring or metal parts to maintain sealing effect.

- High performance butterfly valve has different material options for valve seat, disc and stem, with different material used, high performance butterfly valves can be used for different medias, different pressure and temperature working conditions.

Applications of wafer high performance butterfly valves:

- High performance butterfly valves are used to adjust and cut off the gas flow in sulfuric acid industry, such as furnace front blower, relay blower, electric defogger series and the inlet and outlet of the connecting valve,etc.

- High performance butterfly valve is used in the sulfur combustion, conversion and dry absorption sections of the sulfur acid plant, and is the preferred valve for the sulfur acid plant. It is considered by the majority of the customers as the butterfly valve with good sealing performance, easy operation, corrosion resistance, high temperature resistance, safe and reliable.

- High performance butterfly valves are also widely used in chemical, petrochemical, smelting, pharmaceutical, food, and other industries, with medias like SO2, steam, air, gas, ammonia, CO2 Gas, oil, water, brine, lye, seawater, nitric acid, hydrochloric acid, sulfuric acid,etc.

Standard of wafer high performance butterfly valve:

| Design and Manufacturing | Flange | Inspection and Test | Temperature and Pressure standard |

| API 609 | ASME B16.5 | API 598 | ASME B16.34 |

Material options for main components:

| Component name | Material options |

| Valve body | WCB/CF8/CF8M/CF3/CF3M/Monel/Hastelloy Alloy |

| Valve disc | CF8/CF8M/CF3/CF3M |

| Valve stem | 17-4PH/304/316/1CR13/2CR13 |

| Valve seat | PTFE/RPTFE/PPL |

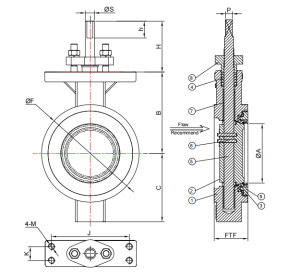

Class 150 wafer type high performance butterfly valve dimension

| NPS | φA | B | C | φF | FTF±3.3 | H | h | φS | P | J | K | M |

| 2″ | 50 | 86 | 70 | 100 | 44 | 42 | 14 | 11.5 | 7 | 125.4 | 22.4 | M10 |

| 2.5″ | 59 | 105 | 81 | 117 | 48 | 81 | 27 | 14.8 | 11.2 | 125.4 | 22.4 | M10 |

| 3″ | 73 | 115 | 92 | 131 | 48 | 81 | 27 | 14.8 | 11.2 | 125.4 | 22.4 | M10 |

| 4″ | 95 | 131 | 110 | 157 | 54 | 81 | 27 | 14.8 | 11.2 | 125.4 | 22.4 | M10 |

| 5″ | 111 | 138 | 119 | 185 | 57 | 81 | 27 | 14.8 | 11.2 | 125.4 | 22.4 | M10 |

| 6″ | 142 | 151 | 134 | 216 | 57 | 81 | 27 | 18 | 14 | 125.4 | 22.4 | M10 |

| 8″ | 188 | 186 | 171 | 270 | 64 | 81 | 27 | 21.9 | 15.9 | 125.4 | 22.4 | M10 |

| 10″ | 236 | 230 | 201 | 325 | 71 | 96 | 28 | 28 | 20.6 | 142.7 | 37.3 | M12 |

| 12″ | 282 | 259 | 240 | 375 | 81 | 96 | 33 | 33.3 | 23.8 | 142.7 | 37.3 | M12 |

| 14″ | 314 | 295 | 277 | 413 | 92 | 105 | 41 | 37 | 28.7 | 142.7 | 37.3 | M16 |

| DN | wafer type: 1.5"-60" |

|---|---|

| PN | Class 150/150LB(Class 300/300LB for option) |

| Media | water, gas, oil |

| End connect | wafer type(lug type and flanged type for option) |