Check valve is one of the widely used industrial valves used in pipelines system to prevent the mediums from flowing back. Usually, there are five common used types of check valves: one is swing check valve, second is lift check valve, third is compression check valve, forth is wafer butterfly type check valve, fifth is line check valve.

A. Lift check valve:

The lift check valve is one kind of check valve whose disc slides along the vertical centerline of the valve body. The lift check valve can only be installed on a horizontal pipeline. The disc can be designed into a ball shape on a high pressure small diameter check valve. The valve body shape is similar like that of the globe valve, so for the lift check valve, its flow resistance is larger. The structure of the lift check valve is similar with the globe valve, and its valve body and disc are same like that of the globe valve. The upper part of the valve disc and the lower part of the bonnet are equipped with guide sleeves, and the valve disc guide sleeve can be freely raised and lowered in the bonnet guide sleeve. When the medium flows downstream, the disc will be opened by the thrust of the medium, when the medium stops flowing, the valve disc falls on the valve seat by itself, preventing the medium from flowing back. The direction of the medium inlet and outlet channels of the straight-through lift check valve is perpendicular to the direction of the valve seat channel. For vertical lift check valve, the direction of the medium inlet and outlet channels is the same as that of the valve seat channel, and the flow resistance of the vertical lift check valve is smaller that that of the straight-through type lift check valve.

B. Swing check valve:

The disc of the swing check valve is in the shape of a round plate, and rotates around the axis of the valve seat channel. Because the flow channel inside the valve body is streamlined, the flow resistance of swing check valve is smaller than that of the lift check valve. It is suitable for large diameter pipelines with low flow rate and infrequent flow changes, and is not suitable for pulsating flow, the swing check valve’s sealing performance is not as good as that of the lift check valve. The swing check valve is divided into three types: single disc swing check valve(single plate/single door swing check valve), double disc swing check valve(or double plate/double door swing check valve), muiti-disc swing check valve(multi-door swing check valve,multi-plate swing check valve). these three types are mainly divided according to the diameter of the swing check valve, are used to reduce the hydraulic shock when the medium stops flowing or flows back.

C. Compression Check Valve

The compression check valve is used for boiler water supply and as the shut off valve for steam. It has the comprehensive function of lift check valve and globe valve or angle valve. In addition, there are some other check valve who are not suitable to be installed in the outlet of the pump, like foot valve, spring type check valve, Y type check valve, etc.

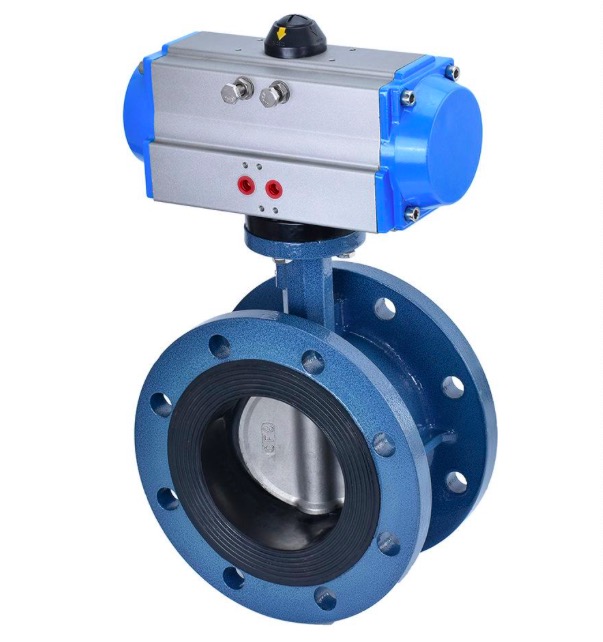

D. Wafer butterfly type check valve.

Wafer butterfly type check valve is one kind of check valve whose disc rotates around the pin in the seat. The wafer butterfly type check valve has a simply structure, can be only installed in horizontal pipelines, and its sealing performance is poor.

E. Line check valve.

Line check valve is a check valve whose disc slides along the centerline of the valve body. Line check valve is a new check valve, which is small in size, light in weight, and good in processing technology. It is one of the development direction of the check valve. However, the fluid resistance coefficient of the line check valve is slightly larger than that of the swing check valve.