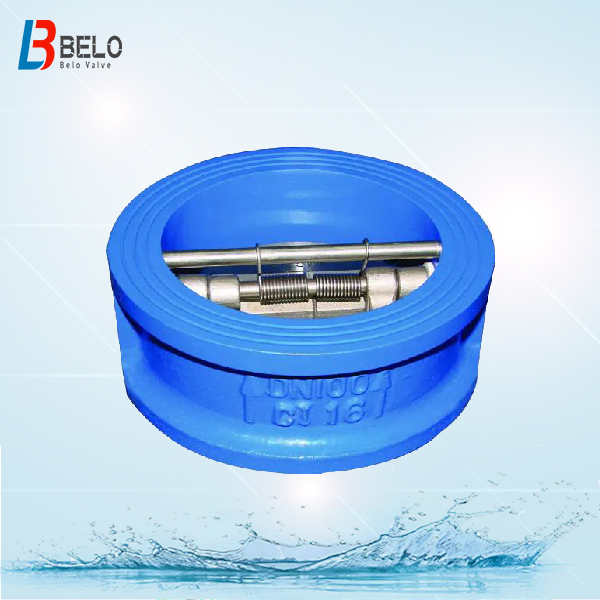

DIN wafer butterfly check valve

Brief introduction of wafer butterfly check valve:

Wafer butterfly check valve consists of valve body with lifting hole, two half-round disc, torsional spring, and rubber valve seat. The disc and seat are sealed very well,so there is no leakage. There are sealing ring at the two sides of the valve body, which can guarantee the efficient sealing even without the sealing gasket.

12 month warranty!!

- Strict inspections before delivery !

- Direct factory price !

- Fast delivery !

Product name: DIN wafer butterfly check valve

Model No.: (DIN) DH76X-16Q-100

Brief introduction of wafer butterfly check valve:

Wafer butterfly check valve consists of valve body with lifting hole, two half-round disc, torsional spring, and rubber valve seat. The disc and seat are sealed very well,so there is no leakage. There are sealing ring at the two sides of the valve body, which can guarantee the efficient sealing even without the sealing gasket.

Characteristics of wafer butterfly check valve:

- simple structure, can only be installed in horizontal pipe systems, better sealing effect.

- The disc can close rapidly under the force of water hammer.

- Small flow resistance.

- Disc closing path is short, the closing force occurred is small.

- The structure is simple and compact.

Applications of wafer butterfly check valve:

This kind of wafer check valve is widely used in petroleum, chemical, pharmacy, electrical power and other industries, and is used for opening and closing pipelines of steam, water, oils.

Standard:

| Design and manufacturing | Face to face | Flange connect | Test and inspection |

| DIN3352 | DIN3202 | DIN2532/2533/2501 | DIN3230 |

Technical specifications:

| Model No | PN(MPa) | Test pressure(MPa) | Mediums | Working temperature | |

| Strength(water) | Seal(water) | ||||

| (DIN)DH76X-10 | 1.0 | 1.5 | 1.1 | Water, oils | ≤80℃ |

| (DIN)DH76X-16 | 1.6 | 2.4 | 1.8 | ||

Material for parts

| Parts name | material |

| Body and deck | Ductile iron/cast iron |

| Disc | Ductile iron/cast iron |

| DN | 50-1200 |

|---|---|

| PN | 1.0Mpa/1.6Mpa/2.5Mpa |

| Mediums | water, steam, oils, strong oxidizing mediums,etc |

| Working temperature | ≤80℃ |