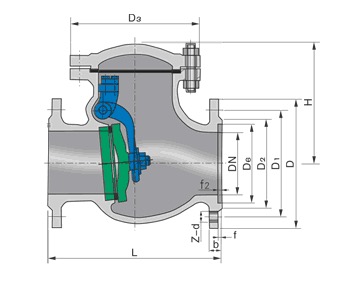

The disc of the swing check valve rotates around the rotating shaft. When the pipeline fluid flows in the specified direction, when the inlet pressure of the valve disc is higher than the outlet pressure, the valve disc is pushed away from the valve seat and the swing check valve is in the open state. When the pressure difference on both sides of the swing check valve decreases to a certain level, the valve disc falls and returns to the closed state to prevent the back flow of the medium.

When would you use a swing check valve?

The fluid resistance of the swing check valve is smaller than that of the lift check valve. It is suitable for pipe lines with larger diameters, and the installation position is not limited. It is usually installed in a horizontal pipelines. According to the number of the valve discs, the swing check valve can be divided into three types: single disc swing check valve, double disc swing check valve, multi disc swing check valve; single door swing check valves are usually used in medium-diameter pipe lines; when using a single door swing check valve for large-diameter pipelines, in order to reduce the water hammering pressure, it is better to choose a slow-closing check valve which can reduce the water hammering pressure. Dual door swing check valve is suitable for large and medium diameter pipelines. Wafer dual door swing check valve is a relatively fast check valve with small structure and light weight; multi-flap swing check valve is suitable for large diameter pipelines;

The swing check valve is suitable for various pipelines with nominal pressure PN1.0Mpa-42.0Mpa, nominal diameter DN15-1200mm, and working temperature of -196℃-540℃ to avoid medium back flow. Swing check valve can be applied to various mediums such as water, steam, oils, nitric acid, acetic acid, strong oxidizing mediums and urea. Swing check valve is mainly used in petroleum, chemical, pharmaceutical, fertilizer, electric power and other industrial pipelines.

Swing type check valve is suitable for clean mediums, not suitable for medium with solid particles and high viscosity.