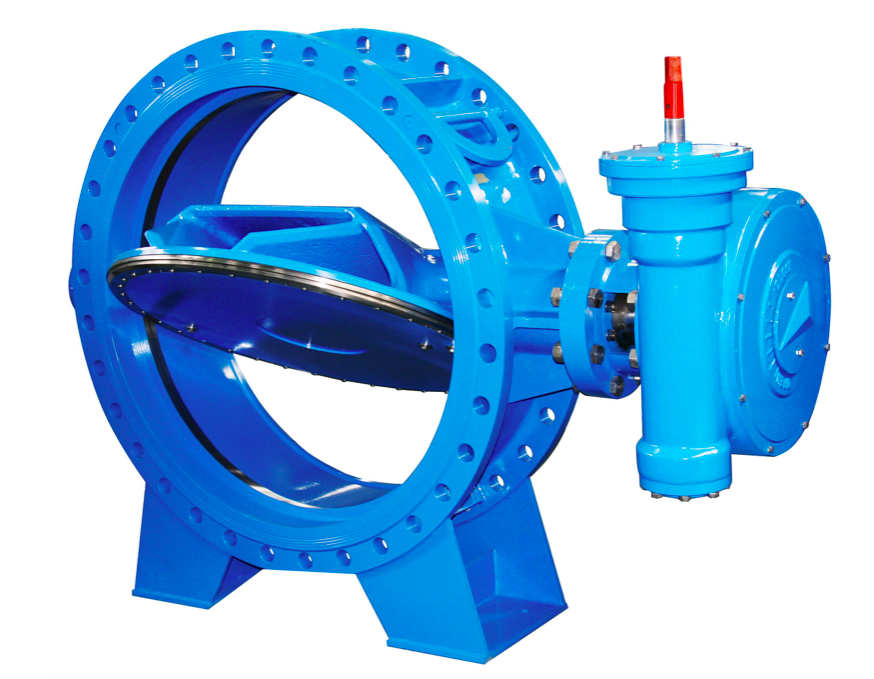

Flange butterfly valve, as its name implies, is a butterfly valve in the form of flange connection. As the control part of the pipeline, the flange butterfly valve plays a very important role in the pipeline, which can be used to cut off the flow of the medium or adjust the flow of the medium in the pipeline. At present, flanged butterfly valves have been widely used in production pipelines in general industries such as water conservancy engineering, water treatment, petroleum, chemical, urban heating, as well as in condensers and cooling water systems in thermal power plants.

Brief introduction of flange butterfly valve

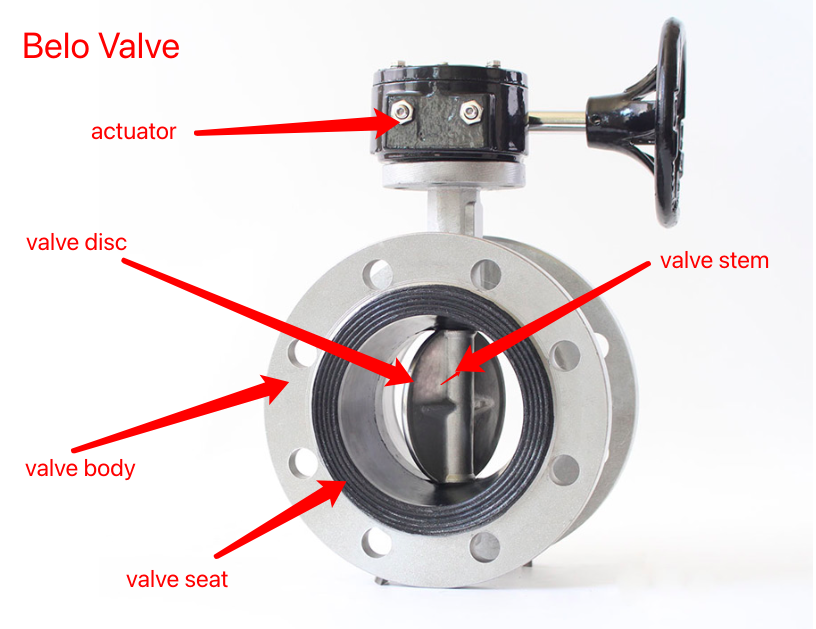

The rotation center of the valve plate in flange butterfly valve is located on the center line of the valve body and the section of the sealing surface of the butterfly plate, the butterfly plate can rotate 90° to achieve opening and closing of the flange butterfly valve, easily and quickly. The valve seat in flange butterfly valve is made of synthetic rubber. When the flange butterfly valve is closing, the outer circular sealing surface of the butterfly plate squeezes the synthetic rubber valve seat, which makes the valve seat elastically deform, thus forming an elastic force as the sealing pressure to ensure the sealing performance of the flange butterfly valve. The sealing structure of the flange butterfly valve adopts PTFE and synthetic rubber to form a composite valve seat. Its characteristics is that the elasticity of the valve is still provided by synthetic rubber, the PTFE which has low friction coefficient, is not easy to wear, not easy to age, is to improve the service life of the flange butterfly valve. The sealing principle and structural characteristics of the flanged butterfly valve are the same as those of the ordinary concentric center line butterfly valve. The sealing structure of the flange butterfly valve adopts PTFE, synthetic rubber and phenolic resin to form a composite valve seat, which makes the valve seat have elasticity and better strength. At the same time, the butterfly plate is fully covered with PTFE, so that the butterfly plate has strong corrosion resistance.

Advantages of flange butterfly valve:

1. the flange butterfly valve is small in size and light in weight, and easy to disassemble and maintain, and can be installed in any position;

2. The flange butterfly valve has simple and compact structure, small operating torque, and can quick open and close after 90° rotation;

3. The flow characteristics of flange butterfly valve tend to be straight, and its adjustment performance is good;

4. The connection between the butterfly plate and the valve stem adopts a pin-free structure, which overcomes the possible internal leakage point.

5. The outer circle of the butterfly plate adopts a spherical shape, which improves the sealing performance and prolongs the service life of the flange butterfly valve. The flange butterfly valve can be open and closed under pressure over 50,000 times with zero leakage;

6. The sealing part of the flange butterfly valve can be replaced, and the sealing is reliable and can achieve bidirectional sealing;

7. The butterfly plate in the flange butterfly valve can be sprayed with coatings such as nylon or PTFE according to user requirements.

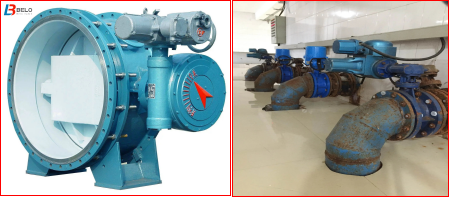

8. The flange butterfly valve can be driven through manual lever handle, worm gear box, electric actuator, pneumatic actuator.

Types of flange butterfly valve:

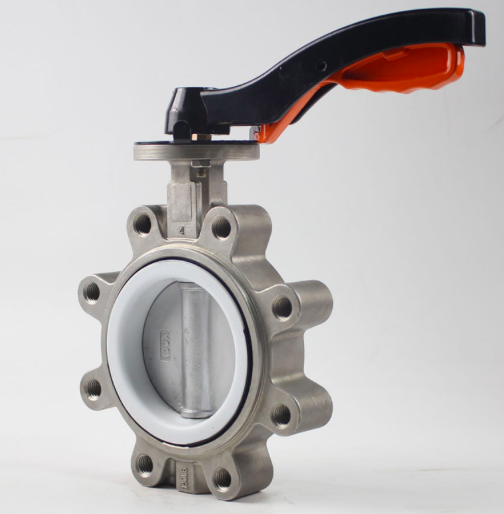

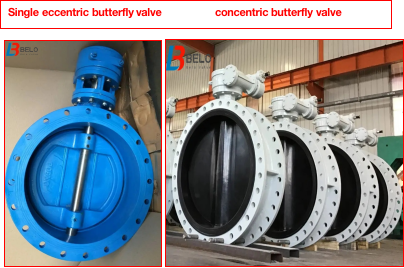

According to structural difference, there are concentric flange butterfly valve(also called center line flange butterfly valve), and eccentric flange butterfly valve( which includes single eccentric flange butterfly valve, double eccentric flange butterfly valve, triple eccentric flange butterfly valve).

According to different sealing material, there are resilient soft seal flange butterfly valve, metal hard seal flange butterfly valve.

With different material used for valve body, there are cast iron flange butterfly valve, ductile cast iron flange butterfly valve, cast steel flange butterfly valve, stainless steel flange butterfly valve.

Applications of flange butterfly valve:

Flange butterfly valve is suitable for pipeline systems with working temperature ≤120℃ or ≤150℃, nominal pressure ≤1.6Mpa, in water supply and drainage, sewage, food, heating, gas, ship, hydro power, metallurgy, energy system and light textile industries, especially suitable for working conditions which need two-way sealing, and where the valve body is easy to corrode, flange butterfly valve is used to regulate flow rate and cut off the medium flow.

1. flange butterfly valve are used to regulate flow rate. When the butterfly valve needs to adjust the flow under special working conditions, when the sealing performance is strictly required, or the working environment of the butterfly valve is harsh, such as severe wear and low temperature,etc; in the above cases, it is necessary to use specially designed metal seal triple offset butterfly valve with adjustment device.

2. Double eccentric flange butterfly valve is suitable to be used as adjustment and throttling device of urban heating, gas supply, water supply, and other engineering pipelines. The applicable medium includes oils and acid and alkali substances;

3. The resilient soft seal flange butterfly valve has good sealing performance, and is suitable for pipelines which requires complete sealing effect and zero leakage. The resilient soft seal flange butterfly valve has good sealing performance, but the disadvantages of resilient soft seal flange butterfly valve is that it is greatly affected by the working temperature, the working temperature of the rubber lined soft sealed flange butterfly valve is 0-80℃, and the working temperature of PTFE lined soft seal flange butterfly valve is -10-150℃. the applicable mediums of resilient soft seal flange butterfly valve are weak acid mediums, such as fresh water, sewage, sea water, salt water, steam, oils,etc;

4. Flange butterfly valves are more suitable for large diameter valves, such as double eccentric flange butterfly valve and triple eccentric flange butterfly valve. Double eccentric flange butterfly valve is suitable for the opening, closing and adjustment of ventilation and dust removal pipelines, and is widely used in ventilation and dust removal pipelines in metallurgy, light industry, electric power, petrochemical and other industries; the triple eccentric metal hard seal flange butterfly valve has a wider range of applications. Triple eccentric metal hard seal flange butterfly valve not only inherits the advantages of high temperature and high pressure resistance of the wafer type metal hard seal butterfly valve, but also has the excellent sealing performance of the resilient soft seal flange butterfly valve. Triple eccentric metal hard seal flange butterfly valve is a good substitute for gate valves, globe valves, and ball valves;

Material options for main parts in resilient soft seal flange butterfly valve

| Valve Body | Ductile cast iron(QT450)/Gray cast iron(HT200)/Cast steel(WCB)/Stainless steel(304,316) |

| Valve disc | stainless steel CF8,CF8M/ductile cast iron/Hastelloy alloy/ 316L/duplex stainless steel |

| valve stem | stainless steel 416,316,304/carbon steel/ stainless steel 17-4PH |

| sealing ring | NBR/EPDM/VITON/SEP/PTFE |

apart from flange butterfly valves, we also have some other butterfly valves, like wafer butterfly valves, lug type butterfly valves, etc;

for more information about flange butterfly valves or other butterfly valves, kindly contact us: