Check valve, also known as one way valve, non return valve, back pressure valve, cut off valve, is one automatic industrial valve, which is widely used in various industrial pipeline systems to prevent the back flow of the medium. Check valves can be divided into lifting type check valve, swing type check valve, butterfly type check valve(also called wafer type check valve), according to their structural differences. Today we are going to discuss the difference between rubber disc check valve and swing check valve:

Rubber disc check valve VS swing check valve:

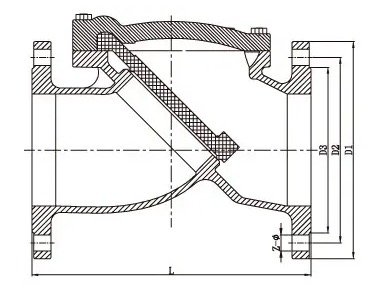

Rubber disc check valve is mainly composed of valve body, bonnet, and the rubber disc. The rubber disc in the check valve is made of steel plate, steel rod and reinforced nylon cloth as the backing, and the outer layer is covered with rubber, and the valve flap can open and close for more than 1 million times.

H44X(SFCV) series of rubber disc check valve adopts full flow design, which has the characteristics of small head loss, not easy to accumulate debris, and easy and convenient to maintain; H44X(SFCV) series of rubber disc check valve is mainly installed in horizontal water supply and drainage systems. Rubber disc check valve can also be installed in the water outlet of the water pump to prevent the back flow and water hammer from damaging the water pump. H44X(SFCV) series of rubber disc check valve can also be installed on the bypass pipe of the water inlet and outlet pipes of the reservoir to prevent the back-flow of pool water flowing back into the water supply system. The rubber disc check valve is usually suitable for clean mediums, and should not be used for mediums containing solid particles and high viscosity.

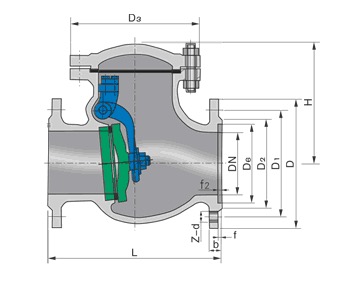

The swing check valve, also known as one way valve, or non return valve, is used to prevent the back flow of the medium in the pipeline. The valve disc which opens and closes by the force of the medium flowing and its own self weight to prevent the medium from flowing back. Check valve is one automatic valve, which only allows the medium to flow in one direction, to prevent accidents. This kind of check valve is widely installed horizontally in pipeline systems. Swing check valve is suitable for various pipeline systems with nominal pressure:

PN1.0MPa~42.0MPa, Class150-2500; nominal diameter DN15~DN1200mm,NPS1/2~48; working temperature -196~540℃.

With different material used for the check valves(like WCB,CF8(M),CF3(M),1Gr5Mo,15CrMo1V), the check valve can be used for various mediums, like water, steam, oils, nitric acid, acetic acid, strong oxidizing medium and urea,etc. Swing check valve is generally used for petroleum, chemical, pharmaceutical, chemical fertilizer, electric power,etc. The swing check valve adopts a built-in rocker arm swing type structure, and all opening and closing components of the swing check valve are installed inside the valve body, and do not penetrate the valve body. Except the middle flange part is using sealing gasket and sealing ring, there is no leakage point in the whole check valve, which prevents the possibility of leakage of the check valve. The connection between the rocker arm and the disc of the swing check valve adopts a spherical connection structure, so that the disc can rotate freely within 360 degree, there is appropriate trace position compensation. The swing check valve is suitable for clean mediums, and should not be used for mediums containing solid particles and high viscosity.

We can find some information above:

Rubber disc check valve and swing check valve are both used to prevent the back flow of the medium, even if they both have the different structural design.