Industrial valve refers to one kind of mechanical equipment which is used in pipelines to open, close and regulate the medium flow. industrial valve includes gate valves, butterfly valves, throttle valves, check valves, globe valves, ball valves, hydraulic control valves, pump valves, fire protection valves, etc. when we are using those industrial valves, most of the time, we have no idea which kind of valve should be used, and what is the difference between some two valves, today we are going to talk about the difference between gate valve and ball valve:

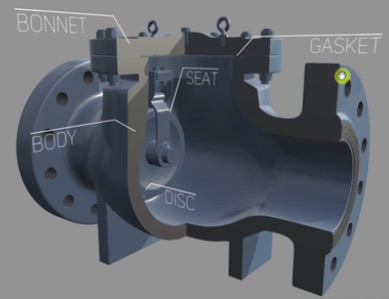

Introduction for gate valve:

Gate valve refers to a valve whose closing part moves in the vertical direction of the channel axis. Gate valve is mainly used to cut off the medium on the pipelines, which is, gate valve can only be fully opened and fully closed. In general, gate valve cannot be used to regulate flow. With different material used, gate valve can be applied to low temperature,low pressure or high temperature and high pressure.

The advantages of gate valve:

① gate valve has small flow resistance;

② gate valve has less torque required for opening and closing;

③ gate valve can be used on the ring network pipeline where the medium flows in two directions, that is, the flow direction of the medium in gate valve is not restricted;

④ when the gate valve is fully open, the sealing surface is less eroded by the working medium than the globe valve;

⑤ the body structure of the gate valve is relatively simple,

⑥ the face to face length of gate valve is relatively short;

Disadvantage of gate valve:

① the external dimensions and opening height of the gate valve are large, and the required installation space is also large;

② During the opening and closing process, the sealing surface is relatively rubbed, and the friction loss is large, and even at the high temperature, it is easy to cause scratches;

③ Generally, gate valves have two sealing surfaces, which makes it difficult to process, grind and maintain;

④ the opening and closing time of gate valve is large;

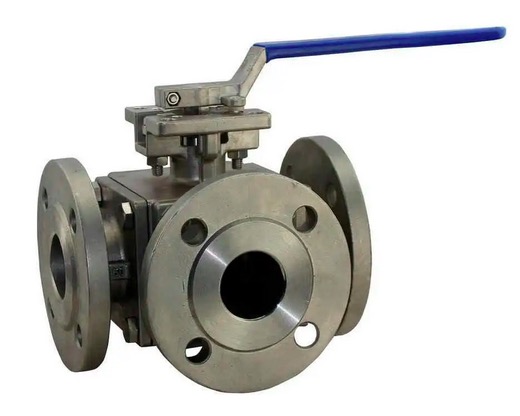

Introduction for ball valve:

Ball valve is evolved from the plug valve. The opening and closing part of ball valve is a sphere, and the sphere is rotated 90° around the axis of the valve stem to achieve the purpose of opening and closing. The ball valve is installed to cut off, distribute and change the flow direction of the medium on the pipeline. The ball valve designed with V-shaped opening also has a good flow adjustment function;

The advantages of ball valves:

① the ball valve has the lowest flow resistance( actually it is 0.)

② ball valve is reliably used in corrosive mediums and low boiling liquids,because ball valves do not get stuck during operation;

③ ball valve can realize complete sealing over a wide pressure and temperature range;

④ ball valve can realize rapid opening and closing, the opening and closing time of some structure is only 0.05s~0.1s;

⑤ when the ball valve is fully opened and fully closed, the sealing surface of the ball body and valve seat is isolated from the medium, so the medium passing through the ball valve at high speed will not cause erosion of the sealing surface.

⑥ ball valve has compact structure and light weight, ball valve can be considered as the most reasonable industrial valve structure for low temperature medium system;

⑦ the closing part can withstand the high differential pressure when closing;

⑧ Ball valve with fully welded valve body can be directly buried in the ground, so that the valve internals are not corroded, and its maximum service life can reach 30 years. It is the most ideal valve for oil and natural gas pipelines;

Disadvantages of ball valve:

① because the most important valve seat sealing material of the ball valve is PTFE, when the sealing material becomes hard, the reliability of the sealing will be damaged, and the temperature resistance level of PTFE is low, only under the condition of less than 180 ℃.

② the adjustment performance of ball valve is worse than that of globe valves, especially for pneumatic ball valves(or electric ball valves);

Here are those widely used gate valves and ball valves, for more information, pls contact us: