Butterfly valve, also known as flap valve, is one kind of regulating valve with simple structure. Butterfly valve that can be used for on-off control of low pressure pipeline medium means that the closing part(disc or butterfly plate) is a disc, which rotates around the valve shaft to achieve opening and closing of the butterfly valve. Butterfly valve can be used to control the flow of various types of fluids such as air, water, steam, various corrosive mediums, mud, oil, liquid metal and radioactive mediums, which mainly plays the role of cutting and throttling on the pipeline. The opening and closing part of butterfly valve is a disc-shaped butterfly plate, which rotates around its own axis in the valve body to achieve the purpose of opening and closing or adjustment.

The main features of butterfly valve:

butterfly valve has small operating torque, small installation space and light weight.

Taking DN1000 valves as an example, the butterfly valve is about 2T, while the gate valve is about 3.5T, and the butterfly valve is easy to combine with various driving devices, and has good durability and reliability. The disadvantage of the rubber sealed butterfly valve is that when it is used for throttling, cavitation will occur due to improper use, which will cause the rubber seat to peel off and damage, so the correct selection depends on the real working conditions. The relationship between the opening of the butterfly valve and the flow is basically a linear proportional change. If it is used to control the flow, its flow characteristics are also closed related to the flow resistance of the piping. For example, the diameter and form of the valves installed in the two pipes are all the same, but the loss coefficient of the pipe is different, and the flow rate of the valve will be very different. If the valve is in a state of large throttling, cavitation is prone to occur on the back of the valve plate, which may damage the valve. Generally, it is used at a distance of 15°。

When the butterfly valve is in the middle opening, the shape of the opening formed by the valve body and the front end of the butterfly plate is centered on the valve shaft, and the two sides are in two different state. One side of the valve body and the valve plate form a nozzle-like opening, and the other side is like a throttle hole-shaped opening. The nozzle side has a much faster flow rate than the throttle side, and negative pressure will be generated under the throttle side valve, often the rubber seal may come off. The operating torque of the butterfly valve varies depending on the opening degree and the opening and closing direction of the valve. For horizontal butterfly valves, especially large-diameter valves, due to the depth of water, the torque generated by the difference between the upper and lower heads of the valve shaft cannot be ignored. In addition, when an elbow is installed on the inlet side of the valve, a biased flow is formed, and the torque will increase. The the valve is in the middle opening, the operating mechanism needs to be self-locking due to the action of the water flow torque.

How butterfly valve works?

Butterfly valve is a kind of valve which uses a disc-shaped opening and closing part to reciprocate about 90°to open,close or adjust the flow of the medium.

Butterfly valve not only has simple structure, small size, light weight, low material consumption,small installation size, small driving torque, simple and fast operation, but also has good flow regulation function and closing sealing features at the same time. Butterfly valve is one of fast developing valves recently. Butterfly valves are widely used. The variety and quantity of its use are still expanding, and butterfly valve is developing towards high temperature, high pressure, large diameter, high sealing performance, long service life, excellent adjustment characteristics, and multi-function in one valve. Its reliability and other performance indicators have reached a high level.

With the application of chemically resistant synthetic rubber on the butterfly valve, the performance of the butterfly valve has been improved. Since synthetic rubber has the characteristics of corrosion resistance, erosion resistance, dimensional stability, good resilience, easy for forming and low cost, synthetic rubber with different properties can be selected according to different use requirements to meet the working conditions of butterfly valves.

Because polytetrafluoroethylene(PTFE in short) has strong corrosion resistance, stable performance, not easy to age, low friction coefficient, easy to form and stable size, and its comprehensive properties can be improved by filling and adding appropriate materials, resulting in better strength and friction,which can get the sealing material for butterfly valve with better strength and low friction coefficient, overcoming the limitation of synthetic rubber. Therefore, polymer materials represented by polytetrafluoroethylene and their filling and modified materials have been widely used in butterfly valves, so that the performance of butterfly valves has been further improved, and therefore butterfly valves with a wider range of temperature and pressure, reliable performance and longer service life have been produced.

In order to meet the application requirements of high and low temperature, strong erosion, long life and other industrial applications, metal sealed butterfly valves have been greatly development. With the application of high temperature resistance, low temperature resistance, strong corrosion resistance, strong erosion resistance, and high strength alloy materials in butterfly valves, metal sealed butterfly valves have been widely used in industrial conditions such as high and low temperature, strong erosion, and long life. Butterfly valves with large diameter(9-750mm),high pressure(42.0Mpa), and wide temperature range(-196~606℃) have appeared. So that butterfly valve technology has reached a new level;

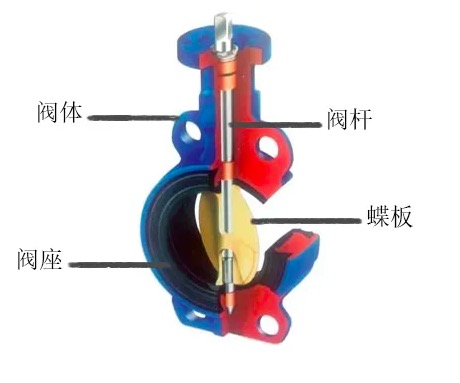

What are the components of butterfly valve?

Butterfly valve mainly composed of valve body, valve stem, valve disc and sealing ring. The valve body is cylindrical, with a short axial length and a built-in butterfly plate.

Advantages of butterfly valve:

1. the opening and closing of butterfly valve is convenient and quick, labor saving, and the fluid resistance is small, which can be operated frequently.

2. Butterfly valve has simple structure, small size, short face to face length, small volume and light weight, it is suitable for large diameter valves.

3. Butterfly valve can be used to transport slurry, with minimal liquid accumulation at the pipe mouth;

4. At low pressure, butterfly valve can achieve a good sealing effect;

5. Butterfly valve has a good regulation performance;

6. When the butterfly valve is fully open, the effective flow area of the valve seat channel is larger and the fluid resistance is smaller;

7. The opening and closing torque of butterfly valve is small, because the discs on both sides of the rotating shaft are basically equally affected by the medium, and the direction of the torque is opposite, so the opening and closing is more labor saving;

8. The sealing surface material in butterfly valve is generally made of rubber and plastic, so in the low pressure condition, the sealing performance is good;

9. Butterfly valve is easy and convenient to install;

10. The operation is flexible and labor saving, manual, electric, pneumatic and hydraulic methods can be selected;

Disadvantages of butterfly valve:

1. the applicable pressure and temperature range of butterfly valve is small;

2. The sealing performance of butterfly valve is relatively poor.

How many types butterfly valves have ?

According to the structure, butterfly valve can be divided into offset plate type butterfly valve, vertical plate type butterfly valve, inclined plate type butterfly valve ad lever type butterfly valve;

According to the sealing material, butterfly valve can be divided into soft sealing butterfly valve and hard sealing butterfly valve(or also called metal sealing butterfly valve). the soft seal butterfly valve is generally using the rubber ring as the sealing material; the hard sealing butterfly valve is using the metal ring as the sealing material;

According to the connection type, butterfly valve can be divided into flange connection butterfly valve and wafer connection butterfly valve;

According to operating mode, butterfly valve has manual butterfly valve, worm gear butterfly valve, pneumatic butterfly valve, hydraulic butterfly valve and electric butterfly valve;

Where butterfly valves are used?

Butterfly valve is suitable for fresh water, sewage, seawater, salt water, steam, natural gas, food, medicine, oil and various acid-base and other pipelines;

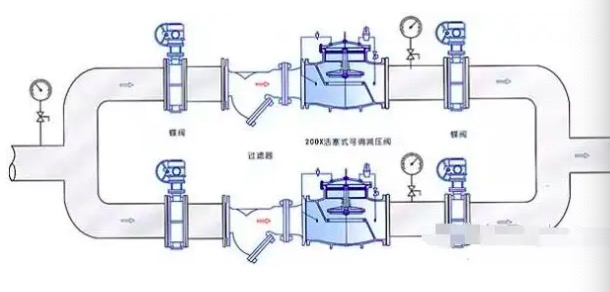

Guidelines for installation of butterfly valve:

1. when installing a butterfly valve, the disc of the butterfly valve should be in a closed state;

2. The opening position should be determined according to the rotation angle of the butterfly plate;

3. For butterfly valve with a bypass valve, the bypass valve should be opened before opening the butterfly valve;

4. The butterfly valve should be installed according to the manufacturer’s installation instructions. For butterfly valves with heavy weight, a firm foundation should be set;

5. The installation position, height, and direction of import and export of butterfly valve must meet the design requirements, and the connection should be firm and tight;

6. All kinds of manual valves installed on the thermal insulation pipeline, the handle lever shall not be downward;

7. Visual inspection must be carried out before the butterfly valve is installed, and the name plate of the butterfly valve should meet the requirements of the current national standard “General Valve Mark” GB12220. for the butterfly valve whose working pressure is greater than 1.0Mpa and plays the role of cutting off the pipe mediums, the strength and sealing performance test should be carried out before installation, and the butterfly valve is allowed to be used after passing the test. During the strength test, the test pressure is 1.5 times the nominal pressure, and the duration is not less than 5 minutes. The valve shell and packing will be qualified with leakage; during the sealing test, the test pressure is 1.1 times the nominal pressure, the test pressure should meet the requirements of GB 50243 during the duration of the test, and the sealing surface of the valve is qualified if there is no leakage;