The metal hard sealed butterfly valve is one kind of butterfly valves. The two sides of the sealing pair of the hard sealed butterfly valve are made of metal; the advantages of metal hard sealed butterfly valve are: high pressure resistance, high temperature resistance, corrosion resistance, and long service life; the disadvantages of metal hard sealing butterfly valve are poor sealing performance, because the two sides of the sealing pair of hard sealed butterfly valve are both metal materials, so there will be a certain amount of leakage after the hard sealed butterfly valve is fully closed;

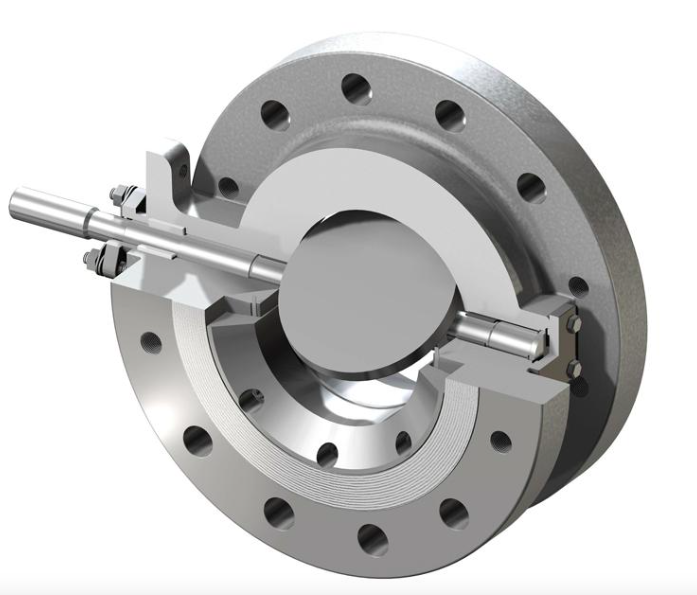

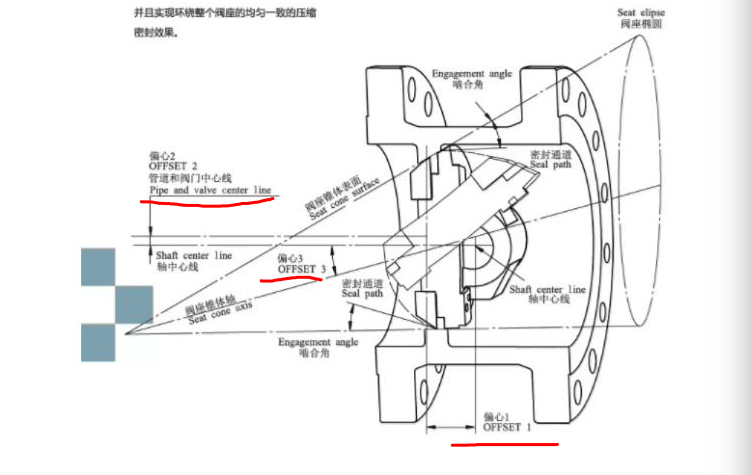

The structures of ordinary hard sealing butterfly valve are double eccentric structure and triple eccentric structure. The structural feature of double eccentric hard sealing butterfly valve is that the stem axis has two eccentricities, the first eccentricity is from the center of the disc, the second eccentricity is from the center of the valve body; this double eccentric structure enables the butterfly plate to quickly leave the valve seat when the butterfly valve is opened, which greatly eliminates the friction and scraping between the butterfly plate and the valve seat, reduces the opening and closing resistance of the butterfly valve, and improves the service life of the valve seat;

The double eccentric head sealing butterfly valve with metal seat is not suitable for high pressure working conditions or pipeline systems which require good sealing performance; since there is no double eccentric butterfly valve which is high temperature resistant and also has good sealing performance at the same time, in order to overcome this contradiction, the butterfly valve has carries out the third eccentric design, the emergence of triple eccentric hard sealing butterfly valve not only solves the problem that the traditional butterfly valve cannot have high temperature resistance and the good sealing performance at the same time, but also further expands the applications scope of the hard sealing butterfly valve.

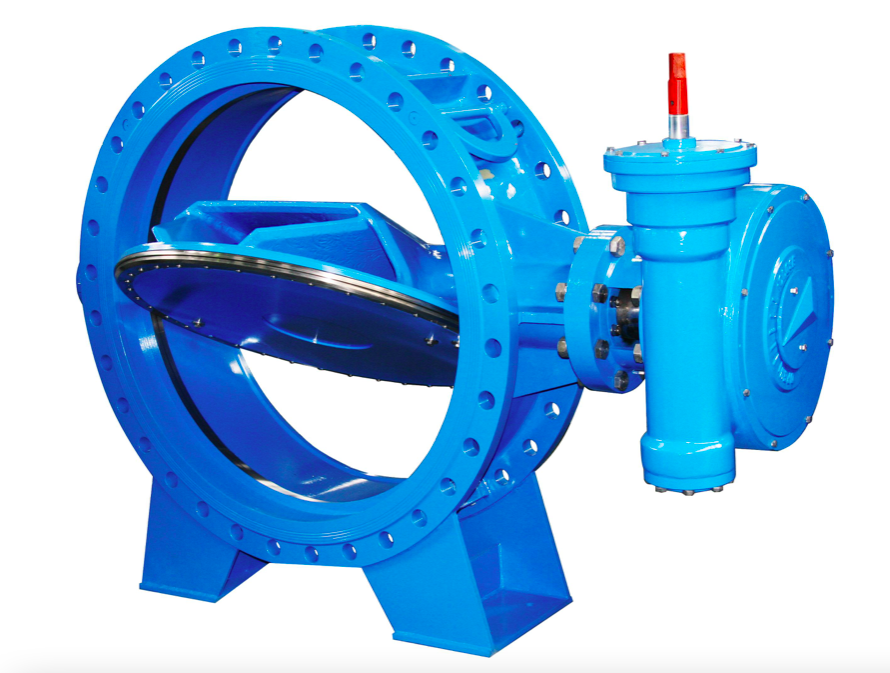

The triple eccentric hard sealing butterfly valve can achieve zero leakage and can be used in more and more various working conditions. Triple eccentric butterfly valve also began to replace other valves in pipeline applications. When used as shut-off valve, triple eccentric butterfly valve can replace gate valves and ball valves; and when used to regulate flow, triple eccentric butterfly valve can replace globe valves; At present, triple eccentric hard sealed butterfly valves are widely used in pipelines in large scale industrial fields such as oil exploration, oil refining, petrochemical, energy, and power generation.

for more informations or prices about double eccentric hard sealing butterfly valves and triple offset hard sealing butterfly valves, kindly contact us: