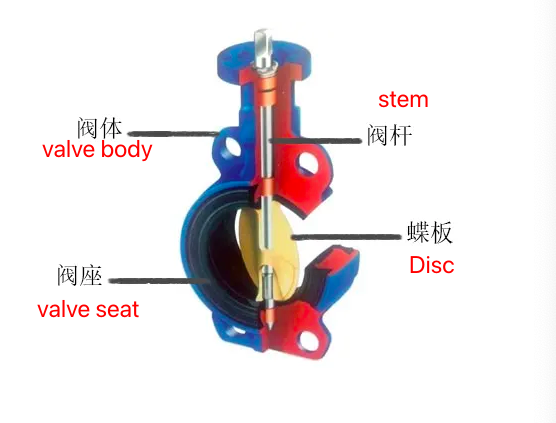

The butterfly valve is a small component installed in the pipeline to control the flow of the medium. The structure of butterfly valve is very simple.

The components that constitute the butterfly valve mainly include the valve body, the valve disc, the valve stem, and the valve seat, plus the actuating device(which includes the manual lever handle, worm gear box, electric actuator, pneumatic actuator). (of course, there are some small connect items like bolts and nuts, pin, bushing). All those main components and the small connect parts form a complete butterfly valve.

This article will introduce you the material for each main components in butterfly valve and the applicable medium and temperature for different materials;

What is valve body in butterfly valve? And what material the valve body can be made of in butterfly valve?

The valve body is one of the most important components of the butterfly valve. The main materials for valve body in butterfly valve are gray iron, ductile iron, cast steel, and stainless steel. According to different working conditions and different pressure levels, different materials and manufacturing technique are used; usually when the pressure level is medium and low pressure, casting is selected for the valve body manufacturing process. When the pressure level is medium and high pressure, the valve body manufacturing process selects forging;

gray cast iron for valve body of butterfly valve:

gray cast iron is the most common material in butterfly valves, which is mainly used in water systems, is easy to be rusted, has a short service life, but the butterfly valve with gray cast iron is cheap;

Ductile cast iron for valve body of butterfly valve:

the performance of ductile cast iron in butterfly valve is comparable to that of the carbon steel. Ductile cast iron butterfly valve is generally used in water system pipes, and it is also the very widely used material for butterfly valve in water systems at present;

Carbon steel for valve body of butterfly valve:

carbon steel butterfly valve can also be used in water systems, but it is not used that much. Carbon steel butterfly valves have high temperature and high pressure resistance. Generally, metal hard sealed butterfly valves are mostly made of carbon steel;

Stainless steel material for valve body of butterfly valve:

stainless steel material has good anti-corrosion and anti-rust properties. And stainless steel butterfly valve is also mostly used in pipelines that need anti-corrosion and anti-rust, and of course, the price stainless steel butterfly valve is relatively higher, compared with the butterfly valve with gray cast iron, ductile cast iron, and carbon steel.

What is valve disc in butterfly valve? And what is the material for valve disc?

The valve disc of the butterfly valve is also called butterfly plate, which connects directly with the mediums, the butterfly valve realizes the flow control of the medium through the movement of the valve disc. The commonly used material for valve disc in butterfly valves are gray cast iron( HT200, HT300,HT350), ductile cast iron( QT400, QT500), carbon steel(WC1, WCB), stainless steel( Austenite 304, 316, 316L; Martensite 1Cr13).

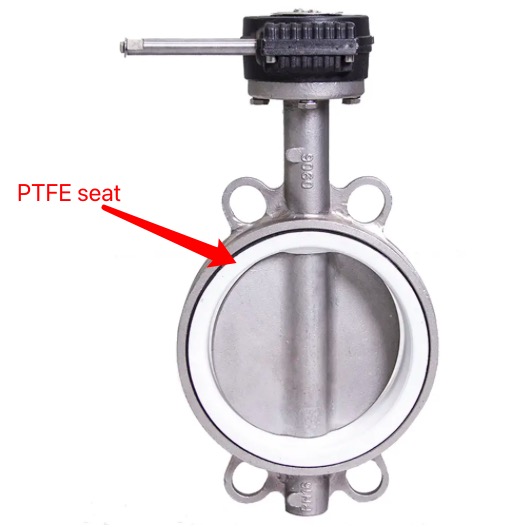

What is the valve seat in butterfly valve? And what is the material for valve seat in butterfly valve?

The valve seat of butterfly valve is also called sealing surface, which is the sealing part in the passage of the butterfly valve body. The material of the valve seat can be divided into soft sealing material and hard sealing material. The most common used soft sealing materials are: natural rubber, nitrile rubber( NBR), EPDM, PTFE;

Butterfly valve with EPDM seated is suitable for medium like water, and steam with working temperature from -20℃-120℃。

Butterfly valve with NBR seated is suitable for oil mediums with temperature 0-80℃。

Butterfly valve with PTFE seated is suitable for corrosive mediums with working temperature below 200℃。

The metal hard sealing materials are copper alloy, chromium series stainless steel, stellite alloy, nickel base alloy and other hard metal alloys;

Butterfly valve with metal hard alloy seated is suitable for working conditions with high temperature and high pressure;

Different material for different medium and temperature:

| material name | Applicable pressure | Applicable temperature | Applicable medium |

| Gray cast iron | ≤1.6Mpa | -15-200℃ | Water, air, gas,etc |

| Ductile cast iron | ≤4.0Mpa | -30-350℃ | Water, seawater, steam, air, gas, etc |

| Carbon steel | ≤32.0Mpa | -29-425℃ | Non-corrosive mediums, including water, oils and steam |

| Alloy steel | High pressure | -30-593℃ | Non-corrosive mediums, including water, oils and steam |

| Stainless steel | -268-649℃ | Corrosive medium/super low temperature/high temperature non corrosive | |

| Copper alloy | -15-200℃ | Oxygen/seawater. |

| Material name | Pressure | temperature | Mediums |

| Natural gas | <2.5Mpa | -50-80℃ | Salts,hydrochloric acid, metal coating liquid,water, wet chlorine,etc |

| NBR | -10-90℃ | Water, oils, waste liquid,etc | |

| EPDM | -20-120℃ | Salt water, 40% boron water, 5%-15% nitric acid,sodium chloride,etc. | |

| PTFE | -70-200℃ | Acid and corrosion resistant. |

what kind of actuating devices the butterfly valve have?

the butterfly valve has manual operating(like manual lever handle, hand wheel(worm gear box), electric actuator, pneumatic actuator.