Butterfly valves are produced with the creation of fluid pipelines. Humans have been using valves for nearly 4000 years. In ancient China, when absorbing brine from salt wells to make salt, wooden plug valves were used in bamboo pipelines. In 1800 BC, when the ancient Egyptians built large-scale water conservancy in order to prevent the flooding of the Nile river, they also used similar wooden plug to control the distribution of the water flow. They are the prototype of the valves the large scale application of industrial valves began after Watt invented the steam engine. At the beginning of the twentieth century, valves of various materials such as cast iron, cast steel, forged steel, stainless steel, chrome molybdenum steel, and brass appeared; those metal industrial valves were used in various industries and various working conditions.

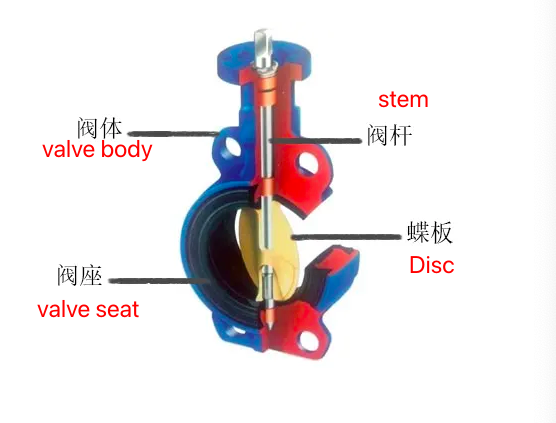

Among those industrial valves, butterfly valve is one of the most used valves. Which is widely used in various pipelines to open, close and regulate the medium flow.

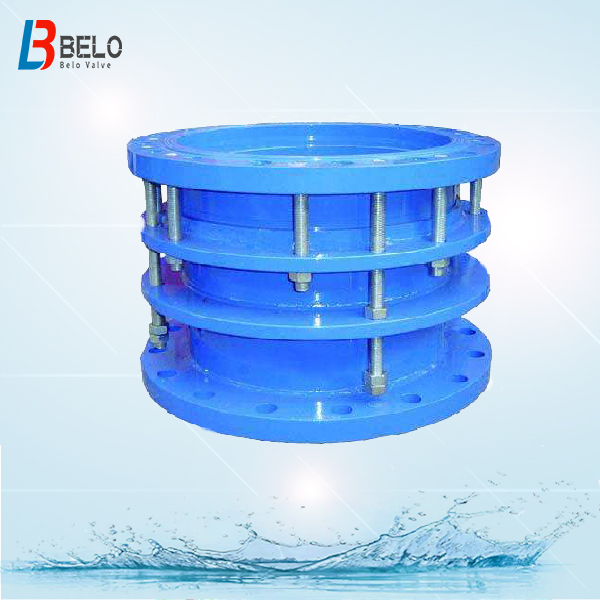

Belo Valve is a more than 15 years professional manufacturer for industrial valves, like butterfly valves( center line wafer butterfly valve, manual butterfly valve, lever driving butterfly valve, butterfly valve with worm gear box, lug type butterfly valve, soft seal butterfly valves, hard seal butterfly valves, flange butterfly valves, ductile cast iron butterfly valves, stainless steel butterfly valve), gate valves(including DINF4 gate valves, DINF5 gate valves, DIN3352 gate valves, rising stem gate valves, non rising stem gate valves, soft seal gate valves, hard seal gate valves, hydraulic gate valves, sluice valves), globe valves( DIN globe valves, bellows globe valves, electric globe valve), ball valves( welded ball valves, soft seal ball valves, stainless steel ball valves, WCB ball valves, ductile cast iron ball valves, API ball valves), check valves( wafer type check valves, swing check valves, rubber disc check valves, ball type check valve, foot valve/bottom valve), fire protection valves( grooved butterfly valves, grooved gate valves, grooved strainers, grooved check valves), hydraulic control valves,etc.

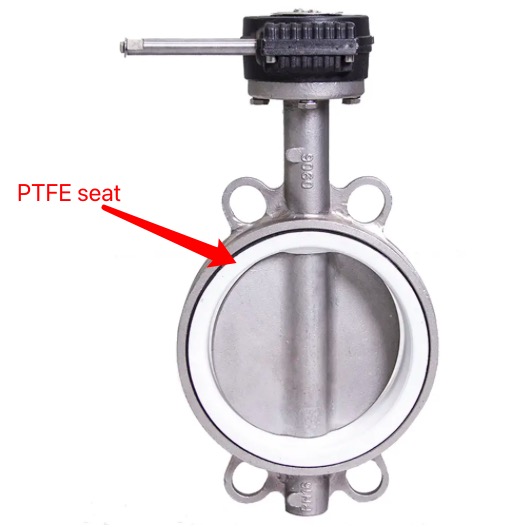

According to end connection, there are flange butterfly valve, and wafer type butterfly valve. With different structure, there are concentric butterfly valve, eccentric butterfly valve. With different material used for valve body, we have ductile iron butterfly valve, gray iron butterfly valve, carbon steel butterfly valve, stainless steel butterfly valve. With different sealing material, there are resilient soft sealing butterfly valve(with EPDM,NBR, PTFE as the sealing material), and metal hard sealing butterfly valve. According to different operating actuator, we have manual lever butterfly valve, electric butterfly valve, pneumatic butterfly valve. With different material used for valve body, sealing surface, and valve disc, butterfly valve can be used for working conditions with different mediums, different pressure, and different temperature;

When the butterfly valve is used in pipelines, some times, there are some leakages around the valve stem, around the valve disc, which confused us a lot, today we are going to discuss why the butterfly valve leaks, and how to fix a leaky butterfly valve:

1. the packing box on the butterfly valve is leaking:

The leakage in the packing box happens a lot, especially in factories;

The reason for why the packing box is leaking:

① the packing material in the butterfly valve is not compatible with the aggressiveness, temperature and pressure of the working medium;

② the filling method of the packing is wrong, especially the whole packing of the butterfly valve is placed in a spiral, which is most likely to cause leakage;

③ the machining accuracy or surface finish of the valve stem in butterfly valve are insufficient, or there are ovality or scoring on the valve stem of the butterfly valve;

④ the valve stem of the butterfly valve is pitted or rusted due to lack of protection in the open air;

⑤ the valve stem of the butterfly valve is bent;

⑥ the packing has been used for too long and has aged;

⑦ the force for operation is too much.

How to fix a leakage around the packing in butterfly valve:

① choose the correct packing material for the butterfly valve;

② fill the packing material into the butterfly valve in a proper way;

③ if the valve stem of the butterfly valve is not properly processed, it needs to be repaired or replaced. The minimum surface finish should reach ▽5, for those butterfly valves in important positions, it should reach ▽8 or above, and there should be no other defects on the valve stem;

④take protective measures to prevent the valve stem of the butterfly valve from corroding, and replace the corroded valve stems;

⑤ the valve stem which has been bent should be straightened or replaced.

⑥ after the packing has been used for a certain period of time, it should be replaced;

⑦ the operation of the butterfly valve should be stable and gentle, open and close the butterfly valve slowly, to prevent sudden temperature changes or medium impact;

2. the sealing part of the butterfly valve is leaking:

Usually, the stuffing box leakage is called external leakage, and the leakage of the sealing part is called internal leakage. The leakage of the sealing part happens inside the valve body, which is difficult to be found;

For sealing part leakage, there are: the leakage of the sealing surface, and the leakage of the root of the sealing ring;

The reason why the sealing part is leaking:

① the sealing surface is ground poorly;

② the sealing ring is not tightly matched with the valve seat and valve disc;

③ the valve disc and the valve stem of the butterfly valve are not firmly connected;

④ the valve stem of the butterfly valve is bent and twisted, and the upper and lower closing part are in the wrong direction;

⑤ the sealing is too fast, the sealing surface of the butterfly valve is not in good contact or has long been damaged;

⑥ the improper sealing material is used, which can not withstand the erosion of the medium;

⑦ Use the globe valve and gate valve as the regulating valve. The sealing surface cannot withstand the erosion of the high speed active mediums;

⑧ some medium will gradually cool down after the butterfly valve is closed, which causes the sealing surface to form slits, and erosion will also occur;

⑨ some sealing surfaces are connected with valve seats and valve discs with thread, which can easily generate oxygen concentration cells and erode loose;

⑩ due to the embedding of impurities such as welding slag, rust, dust, etc, or mechanical parts in the production system falling off and blocking the valve core, the butterfly valve cannot be closed tightly;

How to prevent the sealing part leakage of the butterfly valve:

① before the usage of the butterfly valve, it is necessary to test the pressure and leak carefully. If the the sealing surface is leaking, or the root of the sealing ring is leaking, those leaking issues must be handled well before use;

② it is necessary to check in advance whether the various parts of the butterfly valve are in good condition. Do not use a valve with twisted valve stem or an unreliable connection between the valve disc and valve stem;

③ the butterfly valve should be closed firmly, not violently, if it is found that the contact between the sealing surfaces is not good or there is obstruction, it should be opened a little immediately to let the debris flow out, and then close the butterfly valve carefully;

④ when selecting a butterfly valve, not only the corrosion resistance of the valve body should be considered, but the corrosion resistance of the sealing part also should be considered;

⑤ the valves should be used properly according to their own structural characteristics, the part which need to adjust the flow should use the regulating valve;

⑥ for the case where the medium is cooled and the temperature difference is large after the butterfly valve is closed, the butterfly valve should be closed tightly after the temperature is cooled;

⑦ when the valve seat, valve disc and sealing ring are connected by thread, PTFE can be used as the packing material between the threads, so that there is no open space;

⑧ for butterfly valve where the impurities may fall into, a strainer should be added before that butterfly valve;

3. The valve stem of the butterfly valve couldn’t go up and down:

The reason why the stem of the butterfly valve couldn’t go up and down:

① the thread on the stem is damaged because of violent operation;

② there is lack of lubrication on the valve stem or the lubricant failed;

③ the valve stem is bent or twisted;

④ the surface finish of the valve stem is insufficient;

⑤ the threads on the stem bit too tight;

⑥ the stem nut inclined;

⑦ the material selected is improper, for example, the valve stem and valve stem nut are made of same material, which is easy to bite;

⑧ the thread on the valve stem is corroded by the medium(referring to the valve with non rising stem or valve with stem nut at the bottom);

⑨ there is no protection for the butterfly valves in the open air, the stem thread is covered with dust and sand, or rusted by rain, dew, frost, and snow;

How to prevent the fail of the valve stem in butterfly valve:

① operating gently, do not use violent force when closing the butterfly valve. Do not reach the top dead center when opening, reverse the hand wheel one or two turns after fully opening to make the upper sides of the thread are connected close, so as to prevent the medium from pushing the valve stem upward and impacting;

② check the lubrication condition frequently and keep the normal lubrication condition;

③ Do not open and close the valve with a long lever. Workers who are accustomed to using short levers should control the amount of force to prevent twisting the valve stem(referring to the valve that is directly connected to the hand wheel and the valve stem).

④ improve the quality of processing or repair to meet standard requirements;

⑤ the material used in the butterfly valve should be resistant to erosion, suitable for working temperature and other working conditions;

⑥ Do not use the valve stem nut of the same material as the valve stem;

⑦ when using plastic material as the valve stem nut, it is necessary to check the strength, not only good corrosion resistance and small friction coefficient, but also the strength problem, do not use if the strength is not enough;

⑧ the butterfly valve in the open air should be added valve stem protection cover;

⑨ when the butterfly valve is normally open, the hand wheel should be rolled on schedule to prevent the valve stem from rusting.

For more information about those industrial valves, pls contact us: