Globe valve, also known as stop valve, is a mandatory sealing valve, so when the globe valve is closing, pressure must be applied to the valve disc to force the sealing surface not to leak. When the medium enters the globe valve from the bottom of the valve disc, the resistance that the operating force needs to overcome is the friction force between the valve stem and the packing, and the thrust generated by the pressure of the medium. The force to close the globe valve is greater than the force to open the globe valve, so the diameter of the valve stem in the globe valve should be large, otherwise the failure of the top of the valve stem will occur.

How many end connection types globe valve has?

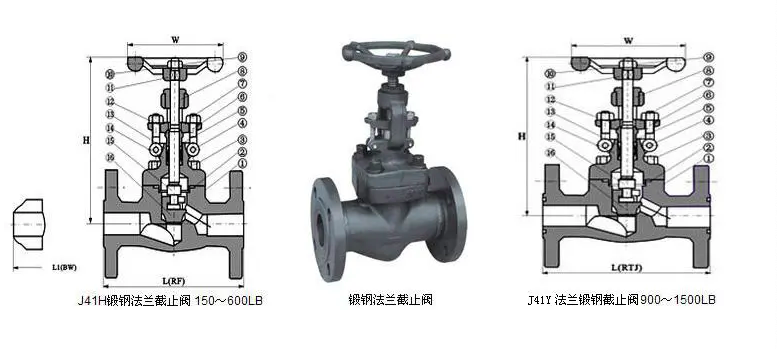

According to the connection method, glove valve is divided into three types: flange connection globe valve, threaded connection globe valve and welding connection globe valve;

How globe valve works?

The opening and closing part of the globe valve(stop valve) is a plug-shaped valve disc. The movement form of the valve stem(common name: non rising stem), also has a lifting and rotating stem type, which can be used to control various types of fluids such as air, water, steam, various corrosive mediums, mud, oil, liquid metal and radioactive medium flow. Therefore, this type of globe valve is very suitable for shut-off or regulation and throttling. Because the valve stem of this type of globe valve has a relatively short opening or closing stroke, and has a very reliable cut-off function, and because the change of the valve seat port is proportional to the stroke of the valve disc, globe valve is very suitable for flow regulation;

How many types globe valve has?

Globe valves are widely used and have many types, the main types are bellows sealing globe valve, flange globe valve, internal thread globe valves, stainless steel globe valve, DC globe valve, needle globe valve, Y-shaped globe valves, angle globe valve, heat insulated globe valve, cast steel globe valve, forged steel globe valve;

Principles for selecting a globe valve:

how to select the proper globe valve is very important, the globe valve needs to be selected according to the characteristics of the medium, temperature, pressure and working conditions. The specific selection rules are as follows:

1. pneumatic globe valves should be selected for pipelines or devices with high temperature and high pressure mediums. Such as high temperature and high pressure pipelines in thermal power plants and petrochemical systems;

2. The direct-flow globe valve should be used on the pipeline where the convection resistance requirements are not strict;

3. Small pneumatic globe valve can choose needle valve, instrument valve, sampling valve, pressure gauge valve,etc.

4. for pipelines there requires flow adjustment or pressure adjustment, but the requirements for adjustment accuracy are not high, and the diameter of pipeline is relatively small. For example, on the pipeline with a nominal diameter ≤ 50mm, it is best to use a pneumatic globe valve and electric control valve;

5. The easy-to-solidify crystallization medium should choose a heat preservation globe valve;

6. For ultra-high pressure working condition, forged globe valves should be selected;

7. Small fertilizers and large fertilizers in synthetic industrial production should choose high pressure angle globe valve or high pressure angle throttle valve with nominal pressure PN160(nominal pressure 16Mpa) or nominal pressure PN320(nominal pressure 32Mpa);

8. In the desiliconization workshop and the pipelines prone to coking in the production of alumina Bayer method, it is suitable to choose the hard metal alloy sealing DC type globe valve or DC type throttle valve with separate valve body, removable valve seat.

9. In the water supply and heating projects in urban construction, the pipeline with smaller nominal diameter, the pneumatic globe valve, balance valve or plunger valve can be selected, for example, in pipeline with nominal diameter less than 150mm.

10. For high temperature, steam, toxic and harmful mediums, the imported bellows sealing globe valves should be selected;

11. For acid-base mediums, the stainless steel globe valve or fluorine lined globe valve should be selected;

For more information about globe valves, please contact us: