Check valve, also called non return valve, back water valve, one way valve, back flow valve, back pressure valve, cut off valve, is used to prevent the back flow of medium in pipelines. The bottom valve(foot valve) installed in the suction end of the water pump is also one kind of check valve.

The valve which opens or closes itself by the flow force of the medium and the weight of the disc to prevent the back flow of the medium is called a check valve( also known as one way valve, non return valve, back water valve, back pressure valve, or cut off valve). the check valve belongs to the automatic valve, which is mainly used in pipelines where the medium flows in one direction, and the check valve only allows the medium to flow in one direction, to prevent accidents.

the most common types of check valve:

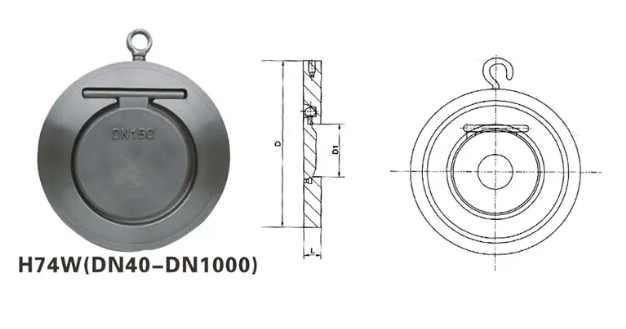

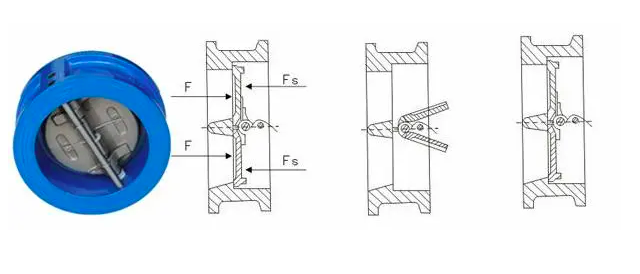

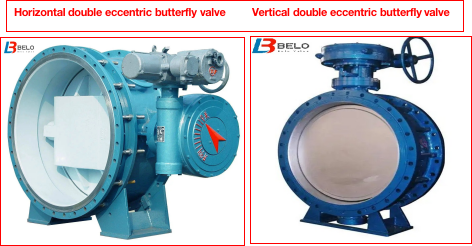

According to their structural difference, check valve can be divided into three types: lifting type check valve, swing type check valve, and wafer butterfly type check valve. (Belo Valve, one professional manufacturer for lifting type check valve, swing type check valve, wafer butterfly type check valve, and other industrial valves).

Lift check valve can be divided into vertical lift check valve and horizontal lift check valve; swing type check valve can be divided into three types: dingle disc swing type check valve, dual disc swing type check valve, multi disc swing type check valve; butterfly type check valve is one kind of straight through check valve.

According to their connection methods, check valve has threaded connection check valve, flange connection check valve, and welded connection check valve.

Installation instructions of check valve:

- Do not place weight on the check valves in the pipeline. Large diameter check valve should be independently supported so that they are not affected by the pressure generated by the piping systems.

- When installing check valves, pay attention to that the flow direction of medium should be consistent with the direction of the arrow on the valve body;

- lifting vertical disc check valve should be installed on vertical pipelines.

- Lift horizontal flap check valve should be installed on horizontal pipe lines.

How many types the check valve has:

Wafer type check valve: H71F-16;

Flange check valve: H44H-16;

High temperature check valve: H42W-16I

High pressure check valve: H61W-160;

Silent check valve(quite check valve): HC42T/X/H(DRVZ);

Rubber disc check valve: HH44X(SFCV);

Rubber ball type check valve: HQ41X,HQ44X,HQ45X;

Silencing check valve: HC41X-16;

Sanitary check valve: H76X/H,H71H,H72H;

Micro resistance slow closing butterfly type check valve: ZHYH46H/W,HH48H/X,HH49H/X;

Wafer disc type check valve: H74X/H-16;

Swing type check valve: H44H-16;

Lifting type check valve: H41H-16;

Energy saving silencing check valve: H41X-16;

Straight through check valve: H42H/N-16;

Anti-fouling isolation valve: HS41X-16;

Wafer dual door check valve; V type high pressure one way valve; S type high pressure one way valve; A type high pressure one way valve; DIF type high pressure one way valve; vertical lift check valve; brass check valve; insulation check valve; multi function check valve; piston check valve; angle type check valve;

The body material used for check valves can be: ductile cast iron, cast iron, cast steel, stainless steel, forged steel;

The working pressure for check valves can be: 1.6-32MPA,150LB-900LB in American Standard, 10K-64K in Japanese Standard;

The working temperature of check valves can be: -20°C- 550°C;

The nominal diameter of check valves can range from DN15-DN600;

The connect methods of check valves can be: flange connection, wafer type connection, threaded connection, welded connection;

The driving methods of check valves can be: manual, worm gear box driving, pneumatic driving, electric driving;

The applicable mediums of check valves are: water, oils, gas and steam;