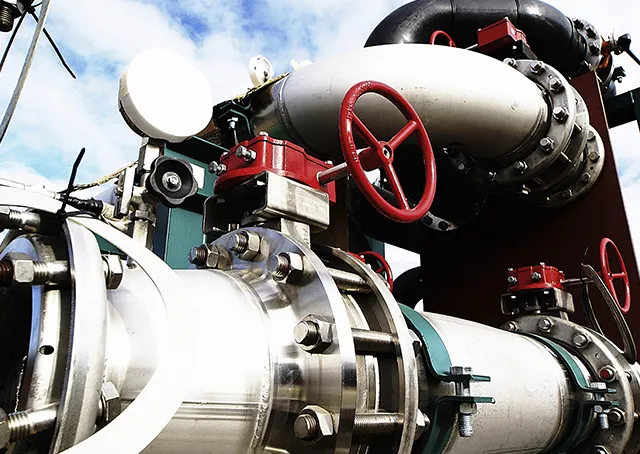

Industrial valve is one widely used, very important mechanism device, which can be used to connect, shut off, regulate the medium flow rate in various industrial pipeline systems.

There are many types of industrial valves, like butterfly valves, gate valves, control valves, regulating valves, balance valves, check valves, globe valves, ball valves, etc.

According to different applicable working pressure, industrial valve can be divided into vacuum industrial valves, low pressure industrial valves, middle pressure industrial valves, high pressure industrial valves, and super high pressure industrial valves;

What is high pressure industrial valves:

For industrial valves, the high pressure industrial valves refer to those valves whose nominal pressure is PN6.4Mpa-64Mpa, or 900LB-4500LB.it is special for high pressure industrial valves in production and material selection. In order to improve various properties of materials, one is to use alloy material, the other is to use appropriate heat treatment. Alloying is to develop some new materials with various special properties by changing the chemical compositions of steel. The heat treatment method does not change the chemical composition of the steel, but applies different heating, heat preservation and cooling to the solid steel to change the physical structure of the steel and improve the performance of the valve material.

High pressure industrial valves can be widely used to control mediums like air, water, steam, mud, oils, liquid metal, and radioactive various corrosive mediums and various types of fluids.

Types of high pressure industrial valves:

The types of high pressure industrial valves mainly include:

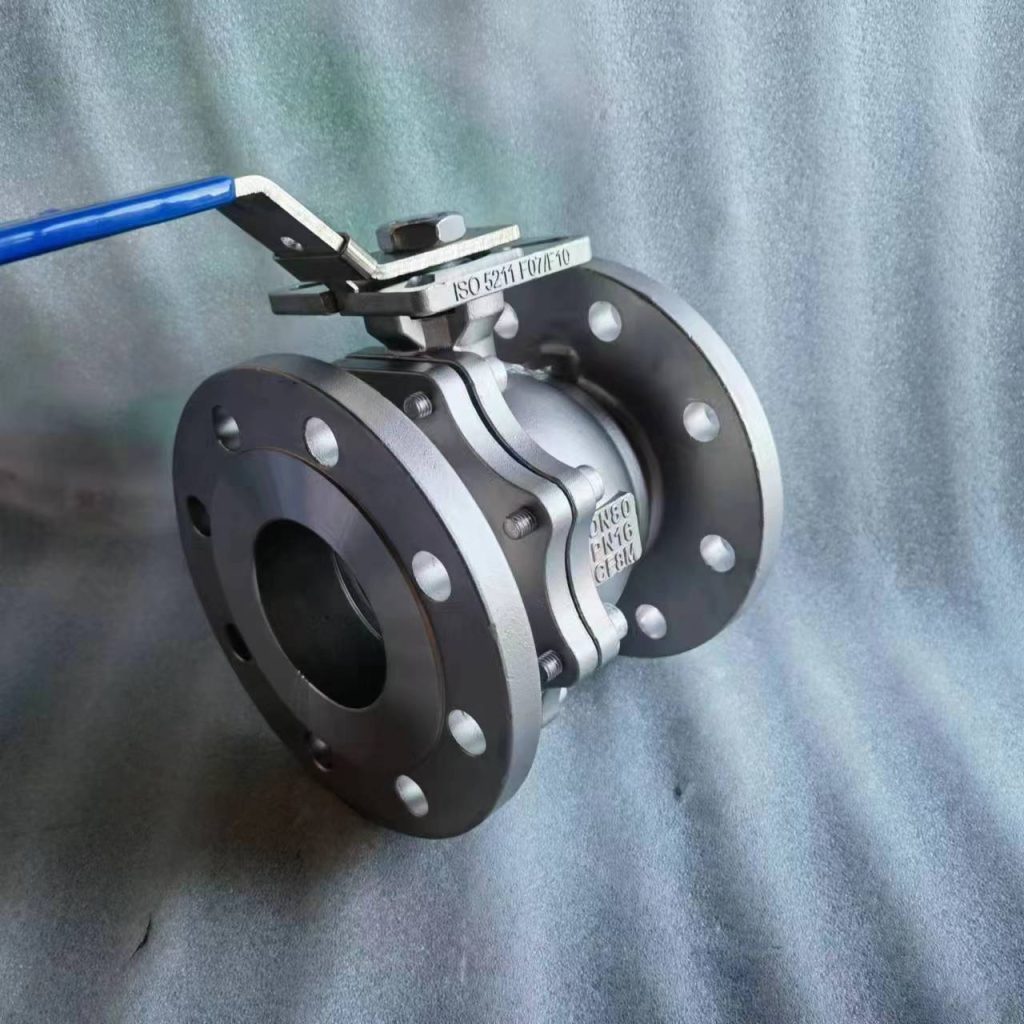

high pressure ball valve, high pressure globe valve, high pressure regulating valve, high pressure gate valve, high pressure butterfly valve, high pressure check valve, high pressure steam trap, high pressure safety valve, high pressure needle valve;

The subcategories are divided into:

high pressure fixed ball valve, high pressure internal thread three-way ball valve, high pressure threaded ball valve, high pressure angle globe valve, high pressure butt welded ball valve, high pressure forged steel check valve, high pressure forged steel gate valve, high pressure Y-shaped globe valve, high pressure forged steel ball valve, high pressure and low temperature globe valve,etc.

Selection and applications of high pressure industrial valves:

In order to prolong the service life and safety performance of high pressure industrial valve, we should also consider the real working conditions and environment when selecting the types of the high pressure valves:

1. Avoid high pressure industrial valves from working under small opening. If the high pressure valve opens with a small lift or slow opening speed, working under small opening will result in small throttling gaps and serious erosion. Appropriately increase the pitch of the locking mechanism, increase the opening speed lift stroke, and the increased working stroke makes the throttling gap to be large, the erosion will be weakened, and the service life of the high pressure valve can be improved.

2. High pressure valves should be avoided from working in high temperature mediums. The medium temperature has a great influence on the service life of the valves. The higher the medium temperature, the shorter the life of the valve, and vice versa. Therefore, adding a cooling device at the pressure relief valve can also significantly improves the service life of the high pressure valves.

3. Under different working pressures, the high pressure valve should use the corresponding sealing pressure, select the appropriate sealing specific pressure, use the torque wrench to lock, or realizes the automatic control of the valve, which can avoid the valve needle to squeeze the valve seat and damaged.

4. Periodically filter the high pressure medium and clean the strainer, add liquid to the filter for filtration. When used frequently, the maintenance period should be appropriately shortened. Clean the high pressure valve properly and timely, to avoid the wear of the high pressure valve by debris.

Belo Valve is a professional supplier for high pressure ball valves, high pressure gate valves, high pressure forged steel check valves, high pressure globe valves, etc, for more information and prices, please contact us: