With the development of economy, various industries prevail. Among them, the chemical industry is growing day by day, which also bring real economic benefits to the valve industry. There are so many types of industrial valves, what kind of industrial valves can be widely used in chemical industry? That’s right, the anti-corrosion fluorine-lined(PTFE lined) industrial valves are the proper options. In the modern chemical industry, PTFE lined industrial valves are required in various working conditions and various pipelines. Because all mediums in chemical industry have chemical components, PTFE lined valves are corrosion resistant, and are very popular in the chemical industry. PTFE lined industry valve is an indispensable spare part for production equipment in the chemical industry.

Applications of PTFE lined industry valves:

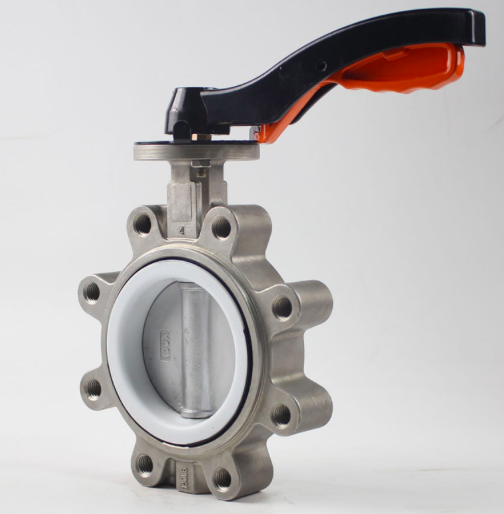

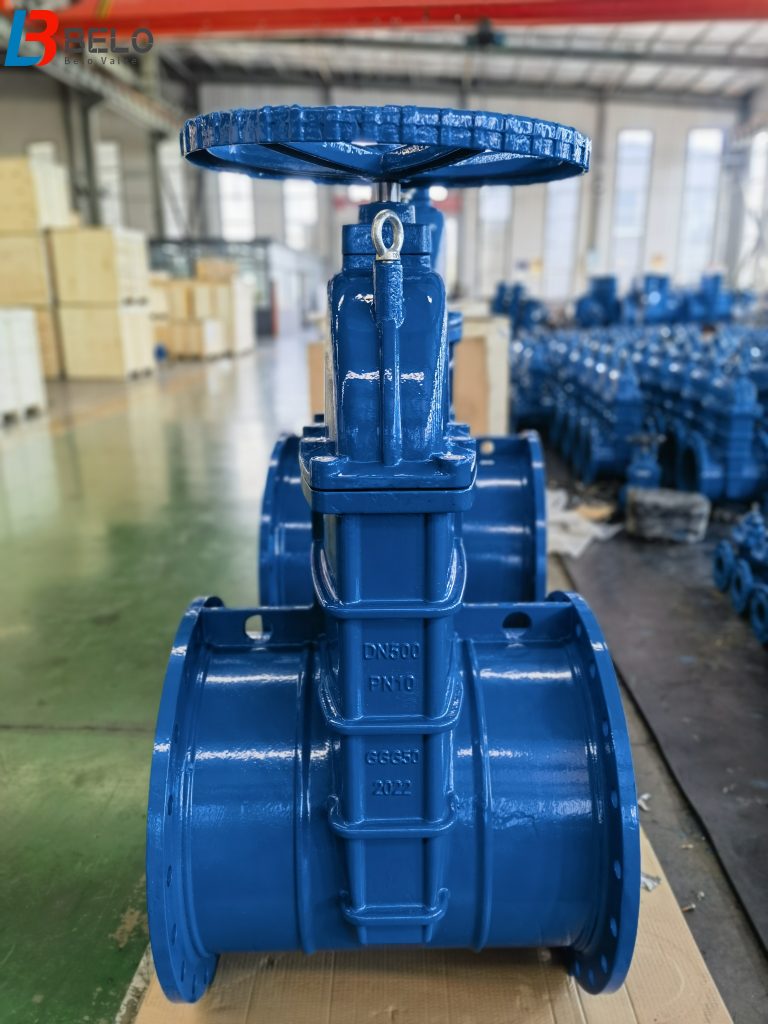

The structure of the anti-corrosion PTFE lined industry valves is actually not as complicated as imagined. The valve channel and all other places which connect with the mediums are lined with fluorine material(F46, F4). The anti-corrosion fluorine-lined valve is a control part in the pipeline fluid conveying system. Its function is to change the chemical pipeline, open and close the mediums, regulate and change the flow direction. It has the function of diversion, cut-off, regulation, throttling, non-return, diversion or overflow. There are plenty industrial valves used for fluid control, from simple butterfly valves, globe valves, gate valves to various complicated valves used in more complex automatic control systems. There are also various anti-corrosive PTFE lined industrial valves with different specifications, which can be used for different working conditions and industrial pipelines.

Types of PTFE lined industrial valves:

There are many types of anti corrosive PTFE lined industrial valves, among which the main categories include: PTFE lined gate valve, PTFE lined butterfly valve, PTFE lined ball valve, PTFE lined safety valve, PTFE lined globe valve, PTFE lined check valve, PTFE lined plug valve, PTFE lined filter, PTFE lined diaphragm valve, PTFE lined pipe fitting, PTFE lined tee, PTFE lined straight-through, PTFE lined four-way, PTFE lined elbow,etc, the sub-categories include: PTFE lined wafer butterfly valve, PTFE lined flange butterfly valve, PTFE lined three way ball valve, pneumatic PTFE lined butterfly valve, electric PTFE lined butterfly valve, electric PTFE lined ball valve, etc.

Advantages and disadvantages of PTFE lined industrial valves:

Advantages of PTFE lined valves:

Lets talk about the advantages of PTFE lined industrial valves. The advantages of PTFE lined valves in the chemical industry depend on their manufacturing process. All parts of the valve connecting with the mediums are made of high-tech full lined PTFE(F46,F4), so fluorine lined industrial valves are suitable for general chemical mediums, and their corrosion resistance is much better than that of those ordinary industrial valves.

Disadvantages of PTFE lined valves:

Because the PTFE lined industrial valve adopts the fluorine-lined process, there must be some defects. The disadvantages of the fluorine lined valve is that it is not suitable for high pressure working conditions and pipelines with fast medium flow rate, because the fluorine lined valve adopts the fluorine lined process, once the pipeline pressure is high and the flow rate of the medium is fast, which will break through the PTFE surface of the valve internal flow channel, resulting in leakage. Therefore, the PTFE lined industrial valve is only suitable for low pressure and low medium flow rate conditions.

Belo Valve is a professional manufacturer and supplier for PTFE lined valves, like PTFE lined butterfly valves, PTFE lined gate valves, PTFE strainers, PTFE lined ball valves, PTFE lined pipe fittings, etc, for more informations or price, kindly contact us: