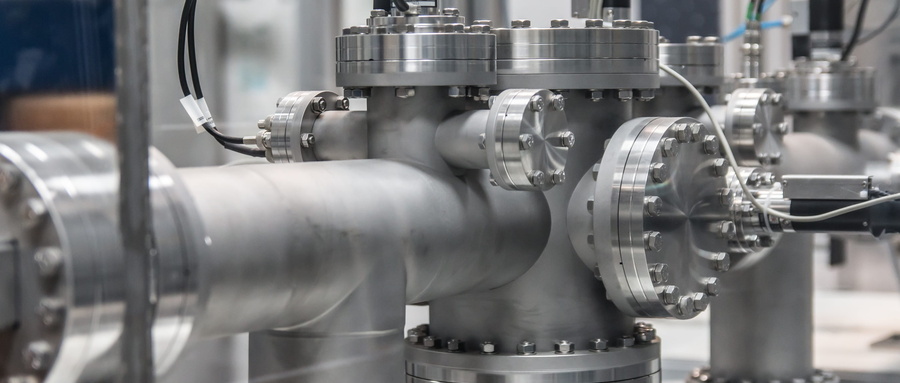

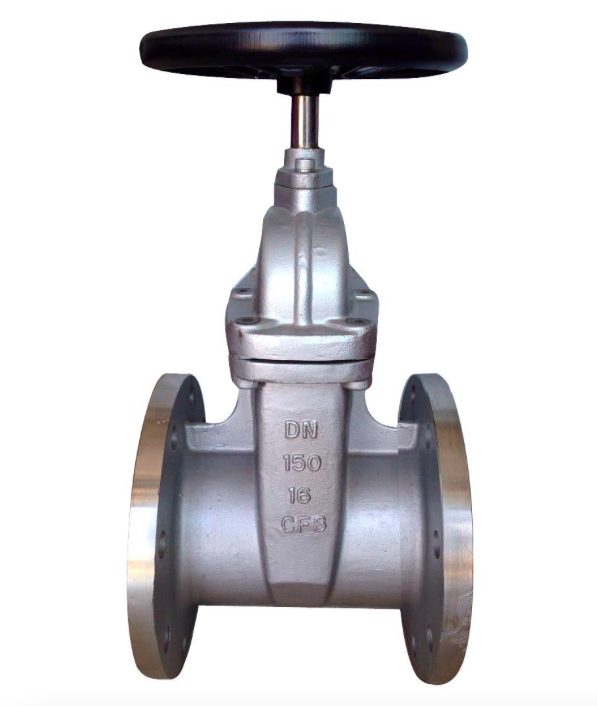

Stainless steel valve has the properties of resistance to slightly corrosive gas and liquid, and also has good anti-rust effect, good heat resistance and temperature resistance, and has certain toughness. At present, the common stainless steel materials in industry are stainless steel 304, 304L, 316 and 316L, they are all stainless steel materials, what are their differences in characteristics and applications? Today, Belo Valve is going to introduce you the differences between stainless steel 304, 304L, stainless steel 316 and 316L.

Introduction of materials stainless steel 304, 304L, 316 and 316L:

About Stainless steel 304:

Stainless steel 304 is one common steel material. As a widely used steel, it has good corrosion resistance, heat resistance, good low temperature strength and mechanical properties; good workability such as stamping and bending, no heat treatment hardening phenomenon(non magnetic, working temperature: -196℃-800℃), its scope of applications: household items(table-wear, cabinets, indoor pipelines, water heaters, boilers, bathtubs); auto-parts(windshield wipers, mufflers, molded products); medical equipment, building materials, chemicals food industry, agriculture, ship parts;

About stainless steel 304L:

As a low carbon 304L steel, its corrosion resistance is similar to that of the 304 steel under normal conditions, its corrosion resistance is excellent after welding or after stress relief; it can also maintain good corrosion resistance without heat treatment. Applicable temperature: -196℃-800℃。Its scope of applications: used in outdoor equipment in the chemical, coal,and petroleum industries that require high corrosion resistance, heat resistant parts of building materials and parts which are difficult to have heat treatment.

About stainless steel 316:

With component of molybdenum inside, stainless steel 316 has excellent corrosion resistance, atmospheric corrosion resistance, and good strength in high temperature, and can be used under harsh conditions; it also has excellent working hardening(non magnetic). its scope of application: equipment used in seawater, chemical, dye, paper making, oxalic acid, fertilizer and other production equipment; photography, food industry, facilities in coastal area, ropes, bolts, nuts;

About 316L stainless steel:

As the low carbon 316 steel, it has the same characteristics with 316 steel, as well its resistance to grain boundary corrosion is excellent. Its scope of application: products with special requirements for resistance to grain boundary corrosion;

Chemical composition of stainless steel 304, 304L, 316,316L :

316 and 316L stainless steel are molybdenum-containing stainless steel. The molybdenum content in 316L stainless steel is slightly higher than that in 316 stainless steel. The overall properties of this 316L stainless steel are better than 316 and 304 stainless steel due to the molybdenum in that steel. Under high temperature conditions, when the concentration of sulfuric acid is lower than 15% and higher than 85%, 316 stainless steel has a wider range of applications. 316 stainless steel also has good resistance to chloride corrosion, so it is often used in marine environments. 316L stainless steel has a max carbon content of 0.03 and can be used in applications where annealing can not be performed after welding and the highest corrosion resistance is required.

| Steel Type | CMax | Mn Max | P Max | C Max | Si Max | Cr | Ni | Mo | Other |

| 304 | 0.08 | 2.0 | 0.045 | 0.03 | 1.0 | 18-20 | 8-12 | – | – |

| 304L | 0.03 | 2.0 | 0.045 | 0.03 | 1.0 | 18-20 | 8-12 | – | – |

| 316 | 0.08 | 2.0 | 0.045 | 0.03 | 1.0 | 16-18 | 10-14 | 2-3 | – |

| 316L | 0.03 | 2.0 | 0.045 | 0.03 | 1.0 | 16-18 | 10-14 | 2-3 | – |

Corrosion resistance of stainless steel 304, 304L, 316, and 316L

The corrosion resistance of 316 stainless steel is better than that of 304 stainless steel, and it has good corrosion resistance in the production process of paper making. And 316 stainless steel is also resistant to marine erosion and corrosive industrial gases. Generally, 304 stainless steel and 316 stainless steel have little difference in chemical corrosion resistance, but there are some differences in some specific mediums. The early development of stainless steel 304, in certain cases, this 304 stainless steel is more sensitive to pitting corrosion. An additional 2-3% of molybdenum reduces this sensitivity, and 316 stainless steel is developed. In addition, these additional molybdenum can also reduce the corrosion of some hot organic acid. 316 stainless steel has almost become one of the standard materials in the food and beverage industry. Due to the worldwide shortage of molybdenum and the higher nickel content in 316 stainless steel, the price of 316 stainless steel is more expansive than that of 304 stainless steel.

Pitting corrosion is a phenomenon caused by deposition corrosion on the surface of stainless steel, which is the inability to form a protective layer of chromium oxide due to lack of oxygen. Especially in small diameter valves, the possibility of deposits on the valve plate is very small, so pitting corrosion rarely occurs. In various types of water mediums( distilled water, drinking water, river water, boiler water, seawater,etc), the corrosion resistance of 304 stainless steel and 316 stainless steel are almost the same, unless the content of chloride ions in the medium is very high, then 316 stainless steel is more suitable.

Heat resistance of stainless steel 304, 304L, 316, 316L

In intermittent use below 1600 degrees and continuous use below 1700 degrees, 316 stainless steel has good oxidation resistance. In the temperature range of 800-1575 degree, but do not use 316 stainless steel continuously, but when 316 stainless steel is used continuously outside this temperature range, this stainless steel has good heat resistance. The carbide precipitation resistance of 316L stainless steel is better than that of 316 stainless steel.

Heat treatment of stainless steel 304, 304L, 316, and 316L:

Annealed in the temperature range of 1850-2050 degrees, then rapidly annealed, then rapidly cooled. 316 stainless steel can not be hardened by overheating.

The welding of stainless steel 304, 304L, 316 and 316L:

316 stainless steel has good weldability. All standard welding methods can be used for welding. According to the usage, 316Cb, 316L or 309Cb stainless steel filler rods or electrodes can be used for welding. In order to obtain good corrosion resistance, the welded section of 316 stainless steel needs to be subjected to post-weld annealing treatment. Post weld annealing is not required if 316L stainless steel is used.

Mechanical Capacity for stainless steel 304, 304L, 316, 316L

Among all types of steels, austenitic stainless steels have very low yield points. Therefore, from the perspective of mechanical properties, austenitic stainless steel is not a good material for valve stem, because in order to ensure a certain strength, the diameter of the valve stem will be increased. Yield point can not be increased by heat treatment, but can be increased by cold forming.

Magnetism of stainless steel 304, 304L, 316, 316L

Due to the widespread use of austenitic stainless steels, people have the false impression that all stainless steel are not magnetic. For austenitic stainless steel, it can be basically understood as non-magnetic, which is true for quenched forged steel. But the stainless steel 304 processed by cold forming will be somewhat magnetic. For cast steel, it is not magnetic if it is 100% austenitic stainless steel.

Low carbon stainless steel-304L and 316L stainless steel:

The corrosion resistance of austenitic stainless steel comes from the protective layer of chromium oxide formed on the metal surface.if the material is heated to temperatures as high as 450℃ to 900℃, the structure of the material changes and chromium carbides form along the edges of the crystals, which prevents the formation of a protective chromium oxide layer at the crystal edges, resulting in reduced corrosion resistance. This corrosion is called “intergranular corrosion”. As a result, 304L stainless steel and 316L stainless steel were developed to combat this corrosion. The carbon content of 304L and 316L stainless steel is very lower, because the carbon content is reduced, so there will be no chromium carbide, and there will be no interfranular corrosion. It should be noted that higher susceptibility to intergranular corrosion does not mean that non-low carbon materials are more susceptible to corrosion. In high chloride environments, this sensitivity is even higher. Note that this phenomenon originates from high temperatures(450℃-900℃). Usually soldering is the direct cause of reaching this temperature. For soft seat butterfly valve, it does not make much sense to use low carbon stainless steel since we do not weld on the disc directly. But in most standards, they ask to use 304L stainless steel or 316L stainless steel as the valve disc.

Belo Valve is a professional manufacturer for stainless steel concentric butterfly valves, stainless steel eccentric butterfly valves, stainless steel gate valves, stainless steel globe valves, stainless steel check valves, stainless steel ball valves, stainless steel strainers, for any inquiry, kindly contact us: