The gate valve,also known as sluice valve, is a widely used industrial valve, whose opening and closing plate moving direction is perpendicular to the direction of the fluid. The gate valve can only be fully opened and fully closed, and can not be used to adjust or throttle. The gate valve is sealing through the contact between the valve seat and the valve plate. Usually the sealing surface of the gate valve is welded with metal material to increase wear resistance, such as 1Cr13, STL6, stainless steel,etc. For the gate plate, there are rigid gate plate and resilient gate plate. According to different gate plate, gate valves can be divided into rigid gate valve(metal hard sealed gate valve) and resilient seated soft sealing gate valve.

Working principle of gate valve:

The opening and closing part of the gate valve is one gate plate, and the movement direction of the plate is perpendicular to the direction of the fluid. The gate valve can only be fully opened and fully closed, and can not be used to regulate or throttle. The gate plate has two sealing surfaces. The two sealing surfaces of the most commonly used gate valve form a wedge shape. The angle of the wedge varies with the gate valve parameters, usually its angle is 5°,the angle is 2°52′ when the medium temperature is not high. The gate plate of the wedge gate valve can be made into a whole part, which is called rigid gate plate; it can also be made into a plate that can produce a small amount of deformation to improve its craftsmanship and make up for the deviation of the sealing surface angle during processing, this kind of gate plate is called resilient gate plate.

when the gate valve is closing, the sealing surface can be sealed only by the medium pressure, that is, relying on the medium pressure to press the sealing surface of the plate to the valve seat on the other side to ensure the sealing effect, which is self-sealing. Most of the gate valve are forcibly sealed, that is, when the gate valve is closing, the plate must be forced against the valve seat by external force to ensure the tightness of the sealing surfaces. The plate of the gate valve moves linearly with the valve stem, which is called a rising stem gate valve or OS&Y gate valve, or lift-stem gate valve. Usually, there are trapezoidal threads on the life stem. Through the nut at the top of the valve and the guide groove on the valve body, the rotary motion is changed into a linear motion, that is, the operating torque is changed into an operating thrust. When the gate valve is opened, when the lifting height of the plate is equal to 1:1 times the diameter of the valve, the fluid channel is completely unobstructed, but this state can not be monitored during operating. In actual application, the apex of the valve stem is used as a sign, that is, when the plate can not be lifted up any more, that position will be the full open position of the gate valve. In case that the temperature change may cause the locking phenomenon, it is turned back 1/2-1 turn once it turns to the top position. For some gate valves, its stem nut is set on the plate, and the rotation of the hand wheel drives the valve stem to rotate, which lifts the valve plate up. This kind of gate valve is called rotating stem gate valve or non rising stem gate valve.

Types of gate valves:

According to the structure of the plate, gate valves can be divided into wedge type gate valve and parallel type gate valve. For wedge type gate valve, there are three different ones: single valve plate gate valve, dual valve plate gate valve and elastic plate gate valve.

According to different stem structure, there are OS&Y gate valve, also known as rising stem gate valve, and non rising stem gate valves;

According to different structure, there are flat type gate valve and knife type gate valve.

According to different operating actuators used, there are manual gate valve,like hand wheel operated gate valve, electric actuated gate valves, pneumatic actuated gate valves,hydraulic gate valve,etc.

According to different material used, there are gray cast iron gate valves, ductile cast iron gate valve, carbon steel gate valve, and stainless steel gate valve, copper alloy gate valve.

With different sealing material used, there are rubber lined resilient seated soft sealing gate valve, PTFE lined resilient seated soft sealing gate valve, and metal to metal seated hard sealing gate valve;

Components of gate valves:

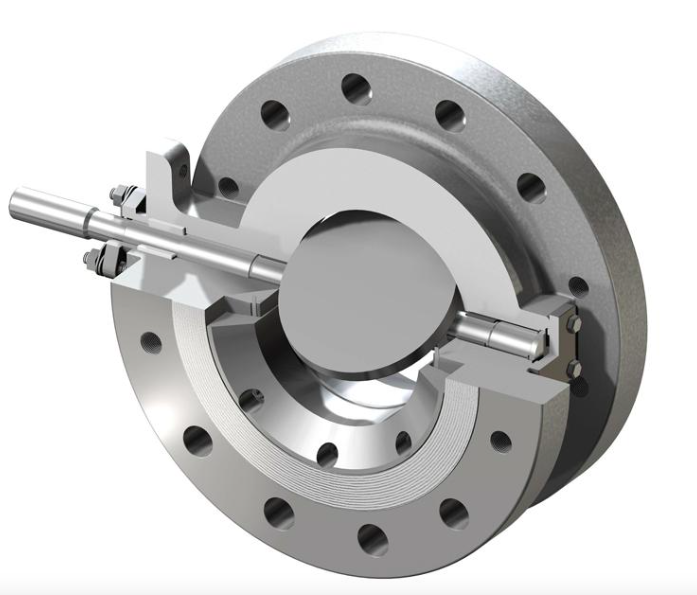

For one gate valve, there are some main items, like valve body, bonnet, operating device, valve plate, stem, apart from those main items, there are also some small parts, like: gasket, packing, bolts and nuts, packing gland, stud,etc.

Advantages and disadvantages of gate valves:

Advantages of gate valves:

- the flow resistance of gate valve is small; the medium channel inside the gate valve is straight, the medium flows in a straight line, and its flow resistance is small;

- For the gate valve, it is more labor-saving when opening and closing, compared with the globe valve, because whether it is opening or closing, the direction of the movement of the plate is perpendicular to the flow direction of the medium.

- The height of the gate valve is large. And its opening and closing time is long. The opening and closing stroke of the plate is large, and the lifting and lowering are carried out by the threaded stem.

- Water hammer phenomenon is not easy to occur. The reason is that its closing time is long.

- The medium can flow in any direction on both sides and is easy to install. The channel of the gate valve is symmetrical on both sides.

- The face to face length (the distance between the two end connecting faces on the shell body) of the gate valve is relatively small.

- The shape of gate valve is simple, its structural length is short, its manufacturing process is good, and its application range is wide.

- The structure of gate valve is compact, its rigid is good, its flow channel is smooth, flow resistance is small, the sealing surface of the gate valve is made of stainless steel and hard alloy, its service life is long, the PTFE packing is used, its sealing performance is reliable, and its operation is light and flexible.

Disadvantages of gate valves:

- Generally, gate valves have two sealing surfaces, which are more complicated to manufacture than globe valves;

- There is relative friction between the sealing surfaces, the wear is large, and it is inconvenient to repair after the sealing surface is worn;

- The structure size of the valve cavity is large, which results in the long structure length, large external dimensions, and large installation space. Large-diameter gate valves are especially bulky.

- The opening and closing time of gate valve is long;

- It may form a closed valve cavity inside the gate valve, so if necessary, a pressure relief structure should be installed to prevent abnormal pressure increase in the middle cavity.