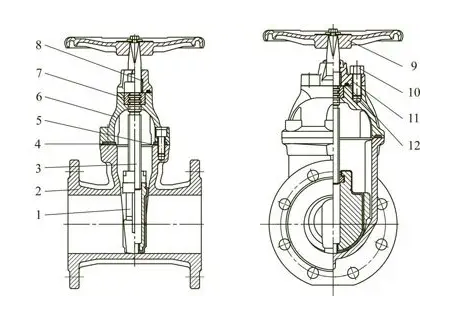

Gate valve, also known as sluice valve, is one industrial valve whose opening and closing part(called gate wedge) moves in the vertical direction of the center line of the passage. The gate valve can only be fully opened and fully closed to cut off the medium flow in the pipeline systems, and can not be used for adjustment and throttling. Gate valve is one widely used industrial valve, generally, for cut-off device with DN≥50mm, gate valves are used, and also for some cut-off device with small diameter, gate valves are also used.

The gate wedge has two sealing surfaces, and that two sealing surfaces form a wedge angle, that wedge angle varies with gate valve parameters. The gate plate of the wedge type gate valve can be made into a whole body, which is called rigid gate plate; it can also be made into a plate that can produce a small amount of deformation to improve its craftsmanship and make up for the deviation of the sealing surface angle during processing. That plate is called an elastic gate plate.

About the sealing of gate valves:

When the gate valve is closed, the sealing surface can be sealed only by the medium pressure, that is, relying on the medium pressure to press the sealing surface of the gate plate to the valve seat on the other side to ensure the sealing effect of the sealing surface, which is called self-sealing. While most of the gate valves are forced to seal, that is, when the gate valve is closed, the gate plate must be forced to the valve seat by external force to ensure the tightness of the sealing surface.

Type of gate valves:

There are many various types of gate valves, with different stem structure, there are non rising stem gate valves, and rising stem gate valves.

For different sealing material used, there are soft sealing gate valves(also called resilient seated gate valves), and metal to metal seated gate valves( also known as hard sealing gate valves).

For different body material, there are gray cast iron gate valves, ductile cast iron gate valves, carbon steel WCB gate valves, stainless steel gate valves, copper alloy gate valves.

For different standards, there are GB gate valves, BS gate valves, DIN gate valves, API gate valves, ANSI AWWA gate valves, JIS gate valves,etc.

Where gate valve is used:

1. gate valves are usually used in opening and closing applications, and can not be used for regulating and throttling.

2. Gate valves are usually installed on horizontal pipelines with stem installed vertically. Gate valves can also be installed on vertical pipes or horizontal pipes where the valve stem is not vertically upward, but special structures may be required depending on the size of the gate valve, the application environment and the specific conditions of the material.

3. For the application environment where the temperature exceeds 260℃, it is recommended to use a flexible or split wedge-shaped gate plate to avoid the wedge gate plate being stuck due to thermal expansion. This can happen when the gate valve is closed with low temperature and opened when the temperature is high.

4. When the gate valve is used in high velocity fluid or thermal cycling applications, to avoid loosening, the threaded valve seat ring should be lock welded on the valve body.

5. After closing the gate valve, the valve stem should swing back slightly to relieve the stem load. Which allows the stem to expand slightly without jamming or damaging the gate valve and without affecting the closing effect.

6. Removing the installation lug on the valve seat ring, the gate valve can be used in hot water outlets or in plumbing systems with soft iron.

7. For the application in pump station, and where there are many debris in the water, which are easy to block the valves in important positions, the manual and electric actuated dual purpose gate valves can be used; otherwise, the butterfly valves can be used, especially in the rebuilt project of pump station. The space of the original pump room can not be changed and achieve the increasing water supply and drainage volume.

Apart from various gate valves, like resilient seated gate valves, metal to metal seated gate valves, DIN gate valves, BS gate valves, API gate valves, AWWA gate valves, GB gate valves, rising stem gate valves, non rising stem gate valves, ductile iron gate valves, gray cast iron gate valves, stainless steel gate valves, Belo Valve can also supply concentric butterfly valves, eccentric butterfly valves, check valve series, globe valves, bellows globe valves, ball valves, and hydraulic control valves.

for any technical questions about those industrial valves, kindly contact us: