Gate valve is one widely used industrial valve, today we are going to introduce you some information about the industrial gate valves, like what is a gate valve? how many type gate valve has? the advantages and disadvantages of gate valves? how many components a gate valve has, etc.

Definition of gate valve:

Gate valve(also known as sluice valve) is one kind of industrial valve whose opening and closing part is driven by the valve stem and moves linearly up and down along the valve seat(the sealing surface) .

Applications of gate valves:

Gate valve is one kind of shut-off valve, which is used to connect or cut off the medium in the pipeline. The gate valve has a wide range of application in industrial projects. The technical parameters of the commonly used gate valves currently produced by Chinese manufacturers are: nominal pressure PN1-760, nominal diameter DN15-1800, the working temperature T≤610℃.

Structural types of gate valves:

According to different structures, gate valves can be divided into rising stem gate valve( OS&Y gate valve), non rising stem gate valve( NRS gate valve in short), fast opening and closing gate valve, reduced bore gate valve, knife type gate valve.

According to different sealing material used, there are resilient seated gate valves and metal to metal seated gate valve;

With different body material used, there are gray cast iron gate valve, ductile cast iron gate valve, carbon steel WCB gate valve, stainless steel gate valves, copper alloy gate valves,etc;

According to different manufacturing technology, there are casting gate valves and forged gate valves;

With different operating device used, there are manual gate valves, electric actuated gate valves, pneumatic actuated gate valves;

According to different standard, there are DIN gate valves, BS gate valves, GB gate valves, API gate valves, ANSI AWWA gate valves, JIS gate valves, etc.

Characteristics of gate valves:

Advantages of gate valves:

1. Gate valve has small fluid resistance. Because the medium channel inside the gate valve body is straight, the flow direction of the medium does not change when it flows through the gate valve, so the fluid resistance of gate valve is small;

2. The opening and closing resistance of gate valve is small. Because the gate wedge movement direction is perpendicular to the medium flow direction when the wedge is opened and closed, compared with the globe valve, the opening and closing of the gate valve is more labor-saving;

3. The direction of the medium flow inside the gate valve is not restricted. The medium can flow in any direction from both sides of the gate valve, which can achieve the purpose of use, and is more suitable for pipelines where the flow direction of the medium may change;

4. The face to face length of gate valve is relatively shorter. Because the gate wedge of the gate valve is placed vertically inside the valve body, and the disc of the globe valve is placed horizontally inside the valve body, so the face to face structural length of the gate valve is shorter than that of the globe valve;

5. The gate valve has great sealing performance. When the gate valve is fully opened, there is less erosion for the sealing surface.

Disadvantages of gate valves:

1. The sealing surface of the gate valve is easily damaged. When opening and closing,there is relative friction between the two sealing surfaces on the valve plate and valve seat, which is easy to damage and affects the sealing performance and the service life of the gate valve.

2. The height of the gate valve is large, and its opening and closing time is long. Since the gate valve must be fully opened or fully closed, the travel of wedge is large, a certain space is required for opening and the overall size of the gate valve is high.

3. The structure of gate valve is complex. There are many components for a gate valve, it is more difficult to manufacture and maintain the gate valve, and the cost for gate valves is higher than that of the globe valves.

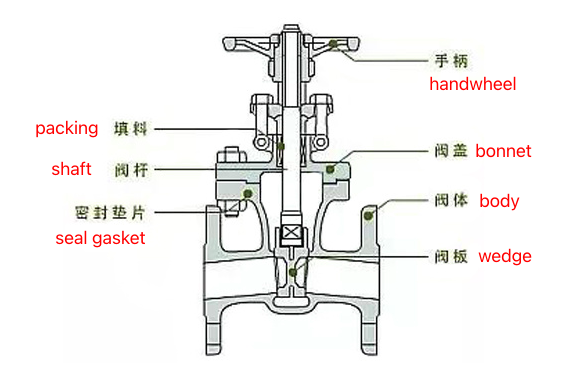

Components of gate valve:

Gate valve is mainly composed of valve body,bonnet, valve stem, valve stem nut, gate wedge, valve seat, stuffing box, sealing packing, packing gland, transmission device,etc.

For large diameter or high pressure gate valves, in order to reduce the opening and closing torque, a bypass valve( stop valve) can be connected in parallel with the inlet and outlet pipelines adjacent to the gate valve. When operating, open the bypass valve first to reduce the pressure difference on both sides of the gate wedge, then open the gate valve. the nominal diameter of the bypass valve is not less than DN32.

1. the valve body is the main part of the gate valve, which is directly connected to the pipeline or equipment and constitutes the pressure bearing part of the medium flow channel. It is an important part for installing the valve bonnet, placing the valve seat and connecting the pipeline. The valve body needs to accommodate the disc-shaped gate plate that is vertical and moves up and down, so the cavity height of the valve body is relatively large. The shape of the valve body section mainly depends on the nominal pressure. For example, the low pressure gate valve body can be designed to be flat to reduce its structural length; the middle cavity of the high and medium pressure gate valve body is mostly designed into an ellipse progressive circle or a circle to improve its pressure bearing capacity and reduce the wall thickness. Most of the medium passages in the valve body have a circular section. For gate valves with larger diameter, in order to reduce the size, opening and closing force and torque of the gate plate, the reduced bore can be designed. The reduced port will increase fluid resistance inside the gate valve, and the pressure drop and energy consumption will also be increased, so the channel reduced ratio should not be too large. Usually the ratio of the diameter of the valve seat channel to the nominal diameter is 0.8-0.95. the blank valve body can be cast, forged, forged welded, cast welded and tube sheet welded. Cast valve body is generally used for diameter ≥DN50, forged valve body is generally for diameter ≤DN50mm.

2. The bonnet is connected with the valve body, and forms the main pressure bearing part of the pressure chamber with the valve body, and there is a stuffing box on it. For the medium and small diameter valves, there is a mechanism on the bonnet to support the stem nut or transmission device.

3. The yoke is connected with the bonnet, and is used to support the valve stem nut or the parts of the transmission device.

4. The stem is directly connected to the stem nut or the transmission device. The polished rod part and the packing form a sealing pair, which can transmit torque to open and close the gate wedge. According to the position of the thread on the valve stem, the gate valve can be divided into rising stem gate valve and non rising stem gate valve.

5. Rising stem gate valve: the rising stem gate valve is one gate valve whose valve stem moves up and down, and its transmission thread is outside of the gate valve body. The lifting and lowering of the valve stem is realized by the rotation of the valve stem nut on the bonnet or yoke. The valve stem nut can only be rotated without moving up and down. Which is convenient to the lubrication of the valve stem, and the opening degree of the gate wedge is clear, the stem thread and stem nut are not in contact with the medium, and are not affected by the temperature and corrosion of the medium, so rising stem gate valves are widely used.

Non rising stem gate valve: for the non rising stem gate valve, the valve stem rotates, its transmission thread is inside the gate valve body. The lifting and lowering of the valve stem is realized by rotating the valve stem to drive the valve stem nut on the gate wedge. The valve stem can only rotate, but does not move up and down. The height of non rising stem gate valve is small, it is difficult to control the opening and closing stroke, the indicator should be installed to show the opening and closing degree of the valve plate. The valve stem thread and valve stem nut are in contact with the medium and are affected by the temperature and corrosion of the medium, so non rising stem gate valves are suitable for non corrosive mediums and occasions with poor external environmental conditions.

6. the valve stem nut and the valve stem thread constitute the parts of the motion pair, which can be directly connected with the transmission device and can transmit torque.

7. The transmission device can directly transmit electricity, pneumatic, hydraulic and human power to the stem or stem nut. In power plants, hand wheels, valve cover, transmission mechanisms, connecting shafts are often used for long distance operating.

8. The valve seat is fixed on the valve body by rolling, welding, screw connection and other methods to form a sealing pair with the gate plate. The valve seat sealing ring can be directly welded with metal on the valve body to form a sealing surface according to customer requirements. For cast iron gate valve, austenitic stainless steel gate valves and copper alloy gate valves, the sealing surface can be also directly machined on the valve body.

9. Packing is fixed inside the stuffing box to prevent the leakage of the medium along the valve stem.

10. The packing gland is a part that compresses the packing through bolts and nuts to prevent the medium from leaking along the valve stem.

11. The valve plate is the opening and closing part of the gate valve, the opening and closing of the gate valve and the sealing performance and service life of the gate valve mainly depends on the gate wedge, which is the key pressure control part of the gate valve. According to the structure of the gate plate, the gate valve can be divided into parallel gate valve and wedge gate valve.

For parallel gate valve, the two sealing surface of the gate plate are parallel to each other and perpendicular to the center line of the valve body passage. The parallel gate valve can be divided into parallel single plate gate valve and parallel double plate gate valve.

For wedge gate valve, the sealing surface is symmetrical with the vertical center line of the plate to form a certain inclination angle, which is called the wedge half angle. The size of the wedge half angle mainly depends on the temperature of the medium and the size of the diameter. Generally, the higher the temperature of the medium, the larger the diameter, the smaller the wedge half angle is. The wedge half angle of the common wedge gate is 2°, 52° and 5°. wedge gate valve can be divided into wedge single plate gate valve and wedge double plate gate valve.

Belo Valve is a more than 15 years professional manufacturer for industrial valves, like butterfly valves( center line wafer butterfly valve, manual butterfly valve, lever driving butterfly valve, butterfly valve with worm gear box, lug type butterfly valve, soft seal butterfly valves, hard seal butterfly valves, flange butterfly valves, ductile cast iron butterfly valves, stainless steel butterfly valve), gate valves(including DINF4 gate valves, DINF5 gate valves, DIN3352 gate valves, rising stem gate valves, non rising stem gate valves, soft seal gate valves, hard seal gate valves, hydraulic gate valves, sluice valves), globe valves( DIN globe valves, bellows globe valves, electric globe valve), ball valves( welded ball valves, soft seal ball valves, stainless steel ball valves, WCB ball valves, ductile cast iron ball valves, API ball valves), check valves( wafer type check valves, swing check valves, rubber disc check valves, ball type check valve, foot valve/bottom valve), fire protection valves( grooved butterfly valves, grooved gate valves, grooved strainers, grooved check valves), hydraulic control valves,etc.

for more information about gate valves, resilient seated gate valves( soft sealing gate valves), metal to metal seated gate valves, cast iron gate valves, ductile iron gate valves, stainless steel gate valves, kindly contact us: