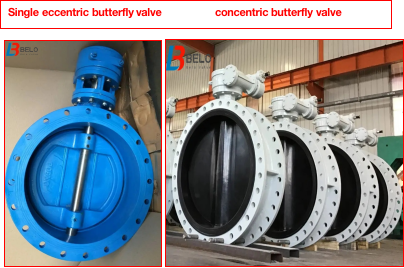

Valve is one important controlling device used in pipeline systems, like gate valves, butterfly valves, ball valves, globe valves, check valves, safety valves, regulating valves, control valves,etc.

While when we are installing those valves, sometimes we can find there is one directional arrow on the valve body, but for some valves, there is not any directional arrow on the valve body? Why for some valves, there is the arrow on the valve body, and for some valves, there is no directional arrow on the valve body? What does that directional arrow mean on the valve body? That is what we are going to talk about:

The arrow marked on the valve body is to indicate the recommended pressure bearing direction of the valve, not to mark the flow direction of the pipeline medium. For those valves with bidirectional sealing structure, it is not a must to mark that directional arrow on the valve body, of course, they can have that directional arrow on their valve body. Because that directional arrow on their valve body is to mark the recommended pressure bearing direction, there are right-left direction and up-down direction, there must be one direction which is better.

The direction of that arrow on the valve body indicates the best pressure bearing direction of the valve, while some installation engineering company use that arrow direction as the medium flow direction in the pipeline, and install those valves accordingly. The wrong installation of the valves will cause leakage or even lead to pipeline accidents.

When the valve is in the closed state after the valve is installed in the pipeline, the direction of the arrow on the valve body should be the recommended pressure bearing direction. If the valve is installed improperly, which may cause the leakage. For some soft sealing ball valves, they are bidirectional sealing ball valves, so there is no arrow to indicate the best pressure bearing direction on the valve body. While even the metal seated hard sealing ball valves can also achieve bidirectional sealing effect, but there must be one direction which is better for pressure bearing, so for those ball valves, you can find the directional arrow on their valve body. Definitely, before we mark the arrow on the valve body, if it is not a must, we can ask the customer’s requirement.

For the metal hard sealing butterfly valves in different positions of the pipeline, the direction of the arrow on the valve body is different from the flow direction of the medium. For example, if that butterfly valve is installed at the outlet end of the water pump in the pump room, the arrow direction on the valve body is opposite to the flow direction of the medium. If that butterfly valve is installed at the inlet end of the water pump, its arrow direction on the valve body is consistent with the flow direction of the medium. So whether the direction of the arrow on the valve body is the direction of the medium flow, it depends on where that valve is installed and the real working conditions.

for more technical information about those industrial valves or price of those valves, kindly contact us: