A gate valve is a type of industrial valve that controls the flow of fluid or gas in a pipeline. It is named after the gate-shaped disc or wedge that slides in and out of the valve body to open or close the passage. When fully open, the gate valve creates a straight, unrestricted path for the medium to flow through. Conversely, when fully closed, the gate valve blocks the flow completely.

Gate valves are commonly used in various industries, including oil and gas, water treatment, chemical processing, power generation, and many others. They are preferred when a reliable, binary on/off control of fluid or gas flow is required.

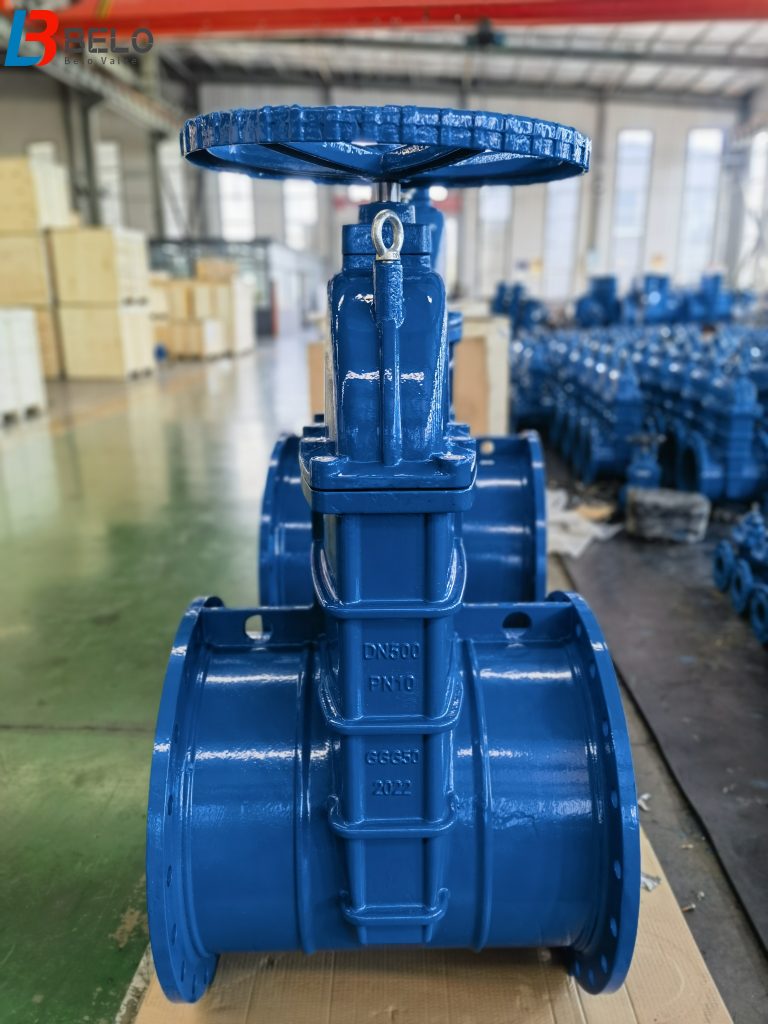

How a gate valve looks like:

Classification of gate valves

with different Stem Structure, gate valves can be divided into rising stem gate valve(also called OS&Y gate valve) and non rising stem gate valve:

a. Rising Stem Gate Valve: In this type, the stem rises and moves linearly as the gate valve is opened or closed, providing a visual indication of the valve position.

b. Non-Rising Stem Gate Valve: In this type, the stem remains stationary as the gate moves up and down. It is suitable for installations with limited vertical space.

with different Standard applied, gate valves can be divided into GB gate valves, DIN F4 gate valves, DIN F5 gate valves, BS 5163 gate valves, API/ANSI gate valves, KS gate valves and JIS gate valves:

a. API 600: Gate valves designed and manufactured according to the American Petroleum Institute (API) Standard 600.

b. BS 5163: Gate valves designed and manufactured according to the British Standard (BS) 5163.

c. DIN/EN Standard: Gate valves designed and manufactured according to the German Standard (DIN) or European Norm (EN) specifications.

with different body Material used, gate valves can be divided into cast iron gate valves, ductile iron gate valves, WCB gate valves, stainless steel gate valves, bronze gate valves, etc:

a. Cast Iron/ductile iron Gate Valve: Gate valves made from cast iron or ductile iron, suitable for low-pressure applications.

b. Cast Steel Gate Valve: Gate valves made from cast steel, offering higher strength and durability for medium to high-pressure applications.

c. Stainless Steel Gate Valve: Gate valves made from stainless steel, providing excellent corrosion resistance and suitable for aggressive media.

d. Bronze Gate Valve: Gate valves made from bronze, often used in applications requiring resistance to seawater or non-corrosive fluids.

with different Sealing Structure, there are metal to metal sealing gate valves and resilient seated or soft sealing gate valves:

a. Metal-to-Metal Sealing Gate Valve: Gate valves with a metal gate and metal seats, providing a tight seal and suitable for high-temperature and high-pressure applications.

b. Resilient seated or Soft Sealing Gate Valve: Gate valves with a gate and seats made of non-metallic materials (such as elastomers or resilient materials) for excellent sealing in low-pressure applications.

with different end connect, gate valves can be divided into flanged gate valves, threaded gate valves and welded gate valves:

a. Flanged Gate Valve: Gate valves with flanged ends for easy installation and maintenance.

b. Threaded Gate Valve: Gate valves with threaded ends for connection to threaded piping systems.

c. Welded Gate Valve: Gate valves with ends designed for welding directly to the pipeline.

with different gate Design, there are wedge gate valves and knife gate valves:

a. Wedge Gate Valve: Gate valves with a solid or split wedge-shaped gate that moves perpendicular to the fluid flow, providing a tight seal.

b. Knife Gate Valve: Gate valves with a sharp-edged gate that cuts through thick or viscous fluids, often used in slurry applications.

These are just some common classifications of gate valves. Depending on specific industry requirements and applications, gate valves may have additional classifications based on factors such as pressure ratings, bore size, actuation type, and more.

how do i choose a gate valve:

Choosing a gate valve involves considering several factors to ensure that it meets your specific requirements. Here are some steps to guide you:

1. Understand your application: Determine the purpose of the gate valve and the specific conditions it will operate under. Consider factors such as the type of fluid or gas, pressure, temperature, flow rate, and the environment in which it will be installed.

2. Valve size: Measure the pipe size or the required flow capacity in order to select the appropriate gate valve size. Gate valves come in various sizes, so choose one that matches your pipeline.

3. Valve material: Identify the material compatibility requirements based on the nature of the fluid or gas flowing through the pipeline. Common materials for gate valves include brass, stainless steel, cast iron and ductile iron, carbon steel/WCB and bronze. Ensure that the valve material is suitable for the medium and operating conditions.

4. Valve type: Gate valves come in two main types: rising stem and non-rising stem. Rising stem gate valves have a stem that moves up and down as the valve opens or closes. Non-rising stem gate valves have a stem that remains stationary while the gate moves up and down. Consider the available space and accessibility in your installation when choosing the appropriate type.

5. Pressure and temperature ratings: Check the pressure and temperature ratings of the gate valve to ensure they match the requirements of your application. These ratings indicate the maximum pressure and temperature limits the valve can handle safely.

6. End connection: Determine the type of end connection required for your application, such as flanged, threaded, or welded connections. Ensure compatibility with your existing piping system. 7. Operational requirements: Consider factors such as the frequency of operation, the need for throttling or modulating flow, and any specific operational features required for your application.

8. Quality and reliability: Choose gate valves from reputable manufacturers known for producing reliable and high-quality products. Consider factors such as warranty, certifications, and customer reviews.

9. Budget: Set a budget for your gate valve selection. While it’s important to consider cost, remember to prioritize quality and reliability to ensure long-term performance.

10. Consult experts if needed: If you’re unsure about any aspect of selecting a gate valve, consult with industry experts or valve suppliers who can provide guidance based on your specific requirements.

Remember to prioritize safety, durability, and performance when choosing a gate valve for your application.

If after reading that article, you still have some questions in selecting the proper gate valves, you can contact our sales direct: