flanged end Y type strainer is also known as flanged end y type filter, which is one important device in various industrial pipeline systems to keep the system clean. today we are going to introduce you some simple information about that flanged end Y type strainer. Hope that article can help you a little, if you need more information, price or technical details about that flanged end Y type strainer, you can contact us direct.

What is a flanged end y type strainer?

A flanged end Y type strainer is a crucial component in many pipelines because it helps to keep the system clean and free of debris that can cause damage or clogs. It is an effective and affordable way to increase the lifespan of pipes and valves. This type of strainer is commonly used in industrial applications such as water treatment, power generation, and chemical processing.

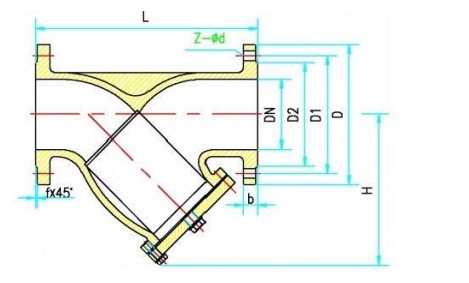

How flanged end Y type strainer looks like:

Specifications of flanged end Y type strainer:

Flanged end Y type strainers are available in a wide range of sizes and materials. Size ranges from 2″ to 16″ inches, while material options include cast iron, ductile cast iron, carbon steel, stainless steel, and other alloys. The strainer comes with a Y-shape configuration where the pipeline is aligned with the strainer’s centerline, and the debris passes through the strainer’s body in a downward or upward flow direction.

Function of flanged end Y type strainer:

The primary function of a flanged end Y type strainer is to prevent debris and other solids from entering downstream systems, such as pumps, valves, and tanks. The y type strainer uses a perforated or mesh screen that captures debris and prevents it from passing along the pipeline. The strainer’s design ensures that the pressure drop across the strainer is low, minimizing the energy required by the system to pump fluid through it.

How to install a flanged end y type strainer:

Installing a flanged end Y type strainer is straightforward. The strainer should be mounted upstream of the equipment it is protecting and, as such, it should be installed in a horizontal pipeline. The valve on the system should be closed, and the strainer’s bolts should be tightened evenly to prevent damage to the seals or gaskets.

The strainer basket should be checked regularly and cleaned when necessary. This will depend on how often the fluid being pumped through the system needs to be replaced. The frequency of checks may range from daily to monthly, depending on the debris levels in the system.

Flanged end Y type strainers are an effective and affordable way to protect downstream systems from debris and other solids. They are commonly used in industrial applications such as water treatment, power generation, and chemical processing. Flanged end Y type strainers are designed for easy installation and use, and they are available in various materials and sizes, making it easy to select the right strainer for your specific application. With regular maintenance and cleaning, the strainer can become a long-lasting part of your pipeline system.