Belo is one professional OEM/ODM manufacturer, direct factory, exporter, trader, wholesale supplier for check valves and gate valves, like swing check valves, rubber disc check valve, rubber ball check valve, wafer dual disc check valve, and also foot valves with cast iron, ductile iron and stainless steel as their body material. Belo Valve can also supply gate valves like GB gate valves, BS gate valves, API/ANSI gate valves,DIN F4/F5 gate valve,AWWA gate valves with rising stem structure and non rising stem structure and diameter from DN40-DN1200, and PN10 and PN16 with cast iron, ductile iron, stainless steel as their body material. today we are going to introduce the differences between check valves and gate valves.

-About check valve. -About gate valve -difference between gate valve and check valve

Brief introduction of check valves:

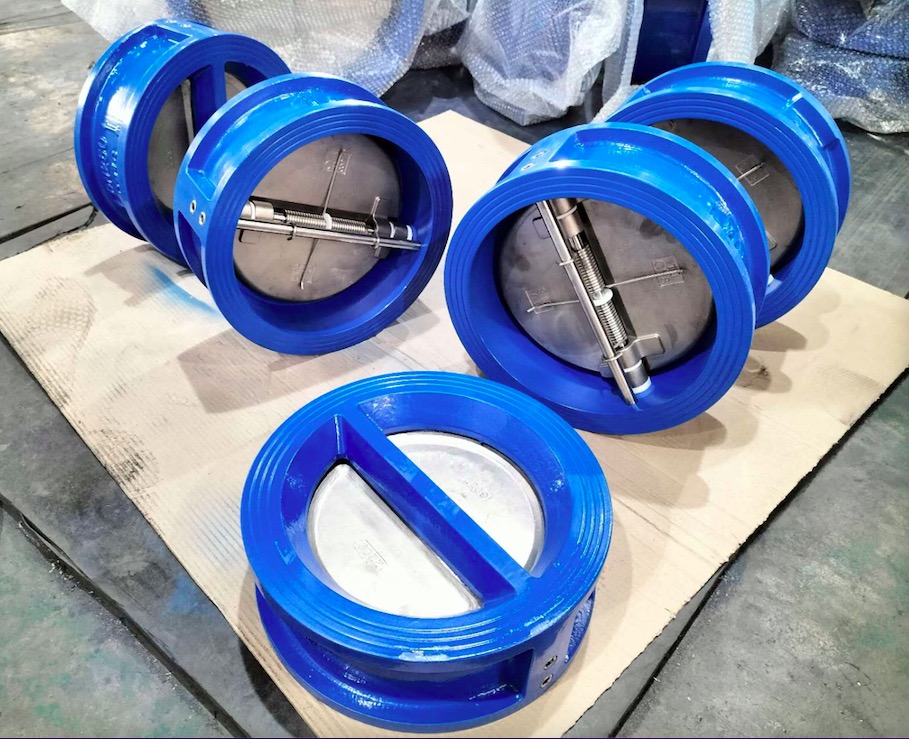

check valve is also called non return valves, is one kind of industrial valve, which is widely used in pipelines to prevent the back flow of the media. while with different design, check valves have swing type check valves, rubber ball check valve, rubber disc check valve, dual disc wafer type check valve, foot valves(or bottom valve some people called).

1. Function: the check valve is also known as a non-return valve or one-way valve, which allows for the flow of fluid in one direction while preventing the back flow in the opposite direction. the check valves automatically open when the fluid flows in the desired direction and close to prevent reverse flow.

2. Design: Check valves typically have a disc or a ball that is pushed to open by the fluid flow and closes under the reverse flow. so check valves are designed to provide a tight seal when closed and minimal resistance to flow when open.

3. Usages: Check valves are commonly applied in plumbing systems, water distribution systems, wastewater treatment plants, oil and gas pipelines, and other applications where back-flow prevention is necessary.

Brief introduction of gate valves:

gate valve is also called sluice valve, is one kind of widely used industrial valve, which is used to open and close the fluid flow. with different design standard, gate valves have GB gate valves, DINF4/F5 gate valves, BS gate valves, JIS gate valves, KS gate valves, AWWA gate valve for water, ANSI/API gate valves, etc. with different stem structure, gate valves can be divided into rising stem gate valve/OS&Y gate valves, and non rising stem gate valves. with different sealing material used, gate valves have resilient seated soft sealing gate valves and metal to metal seated hard sealing gate valves.

1. Function: the gate valve controls the flow of fluid by using a gate or wedge-shaped disc that moves up and down to open or close the gate valve. It provides a straight-through flow path when fully open and provides a tight shut-off when the gate valve is fully closed.

2. Design: those Gate valves have a gate or disc/plate which moves perpendicular to the flow direction. When the gate is lifted, it allows for full flow, and when it is lowered, it obstructs the flow to shut off the valve.

3. Usages: Gate valves are commonly used in various industries, including oil and gas, water treatment, power plants, and chemical processing. They are suitable for applications where a straight-through flow path, high flow capacity, and tight shut-off are required.

Main differences between check valve and gate valve:

check valve and gate valve have some differences in flow control, design and operation, installation direction and applications.

1. check valve and gate valve are different in Flow Control: Check valves allow the media to flow in one direction and prevent back-flow of the media in the pipeline.

while gate valves control flow in both directions and provide the ability to completely shut off the flow.

2. check valve and gate valve have difference in structural design: the structural design of the gate valve consists of a gate plate, valve body, valve bonnet, valve stem, valve seat(can be rubber material or metal material) and the operating mechanism. the function of the gate plate is to control the flow of the fluid by cooperating with the valve seat. as the gate plate rises, the valve plate moves up to keep the flow channel open, then the fluid can go through the gate valve fluently. the operating device of the gate valve can be the manual hand wheel, or the bevel gear, or the electrical actuator, pneumatic actuator.

the structural design of check valves consists of a valve body, a valve disc(or the rubber ball), and a spring. the function of the valve disc is to control the flow direction of the fluid, which is usually divided into two types: one way and two way. the function of the spring is to keep the check valve open during forward movement. Only when the fluid moves in the reverse direction, the spring will be compressed and forced to close the check valve to prevent the back flow of the fluid.

3. check valve and gate valve have different applications: check valves are generally installed on the inlet and outlet of water pumps, the outlet of pump stations, and the middle pipelines of fire prevention water supply systems to prevent the harm caused by the back flow of the media.

the gate valve is generally used in industrial pipelines, mainly used to cut off or adjust the flow and pressure of the media, and is usually used to cut off the inlet and outlet pipelines of the equipment.

Finally, check valves and gate valves have some differences in structural design, flow control and applications, we should select the proper valves according to the real working conditions, if you have no idea how to select the right industrial valve, whether a check valve or a gate valve should be selected, please contact our sales direct.