Industrial Valves play a crucial role in regulating and controlling the flow of fluids in various industries. Two popular types of industrial valves used extensively are gate valves and butterfly valves. While both valves serve similar purposes, they differ significantly in design, function, and applications. This article aims to explore the differences between gate valves and butterfly valves, including their types, advantages, disadvantages, and how they work.

What is a Gate Valve?

A gate valve is a type of linear motion industrial valve which controls the flow of fluid by raising or lowering a gate or wedge that slides across the flow path. The gate is typically made of metal and can completely shut off the flow when closed. Gate valves are commonly used in applications that require on/off control, such as oil and gas pipelines, refineries, and petrochemical plants.

Common Types of Gate Valves:

Rising Stem Gate Valve/OS&Y gate valve: The position of the gate is indicated by the rising stem outside the valve body.

Non-rising Stem Gate Valve: The gate remains in a fixed position, and the stem threads are contained within the valve body.

Wedge Gate Valve: The gate has a wedge-shaped design, providing a tight seal when closed.

Knife Gate Valve: This type of gate valve uses a sharp-edged gate to cut through solids and highly viscous fluids.

How knife gate valve looks like:

How Gate Valves Work:

Gate valves operate by raising or lowering the gate or wedge between the valve body and the seat. When fully open, the gate retracts into the bonnet, allowing uninterrupted flow. To close the gate valve, the gate is lowered to create a tight seal against the seat, blocking the flow.

Advantages of Gate Valve:

Gate valves can Provide full and unobstructed flow when fully open.

Gate valves are Suitable for high-pressure and high-temperature applications.

Gate valves are Excellent shut-off capability, minimizing leakage.

Disadvantages of Gate Valve:

Gate valves are Slow to operate, requiring multiple turns to fully open or close.

Gate valves are More prone to erosion and damage compared to other valve types.

Gate valves are Not suitable for regulating flow; typically used for isolation purposes only.

What is a Butterfly Valve?

A butterfly valve is a quarter-turn industrial valve that uses a metal disc or vane mounted on a rod as the closure element. The valve disc rotates perpendicular to the flow path to control the fluid flow. Butterfly valves are commonly used in applications requiring moderate flow control, such as HVAC systems, water treatment plants, and food processing industries.

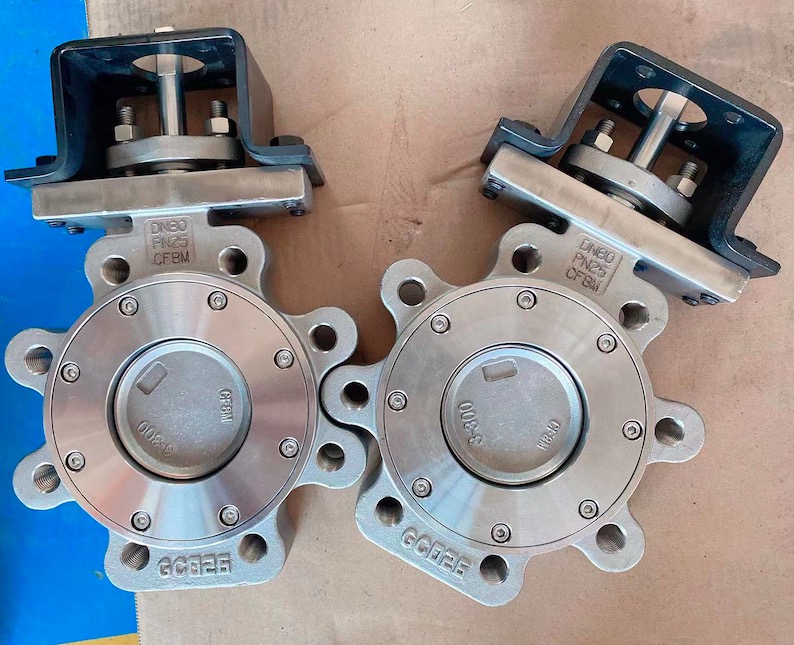

How butterfly valves look like:

Common Types of Butterfly Valves:

with different structural design, butterfly valves can be divided into concentric butterfly valves and eccentric butterfly valves, with different end connect, concentric butterfly valves can be divided into wafer end concentric butterfly valves, lug style concentric butterfly valves, flanged type concentric butterfly valves. eccentric butterfly valve can be divided into single eccentric butterfly valves, double eccentric butterfly valves, triple eccentric butterfly valves.

Wafer Butterfly Valve: This type of butterfly valve is designed to fit between pipeline flanges, providing a low-profile and lightweight solution.

Lug Butterfly Valve: The valve has threaded inserts on both sides, allowing it to be installed in the pipeline without additional flanges.

Double eccentric/Offset Butterfly Valve: in double eccentric butterfly valves, The position of the disc is offset from the centerline of the valve, reducing sealing friction and increasing seat life.

Triple eccentric/Offset Butterfly Valve: This advanced design incorporates three offsets to achieve a tight shut-off, making it suitable for high-performance applications, like high temperature and high pressure working conditions.

Advantages of Butterfly Valves:

butterfly valves have Quick and easy operation with a quarter-turn of the handle.

butterfly valves have Compact design and are light in weight, which can save installation space and manufacturing cost.

butterfly valves are Suitable for applications requiring moderate flow control.

Disadvantages of Butterfly Valves:

Butterfly valves have Less effective shut-off capability compared to gate valves.

Butterfly valves are Prone to cavitation and high-pressure drops when partially open.

Butterfly valves have Limited operating temperature and pressure range.

How Butterfly Valves Work:

Butterfly valves work by rotating a disc or vane perpendicular to the flow path. In the open position, the disc sits parallel to the flow, allowing fluid to pass freely. By rotating the disc 90 degrees, it becomes perpendicular to the flow, effectively closing the butterfly valve and preventing flow.

Differences Between Gate Valve and Butterfly Valve:

Gate valves and butterfly valves are different in Design: Gate valves use a linear motion gate or wedge, while butterfly valves use a rotating disc.

Gate valves and butterfly valves have different Applications: Gate valves are primarily used for on/off control, while butterfly valves are suitable for moderate flow control.

Gate valves and butterfly valves have different Shut-off Capability: Gate valves provide a tighter shut-off compared to butterfly valves.

Gate valves and butterfly valves have different Size and Weight: with the same diameter and pressure specifications, Butterfly valves are typically more compact and lightweight than gate valves.

Gate valves and butterfly valves have different Operating Speed: Butterfly valves operate quickly with a quarter-turn, while gate valves require multiple turns to open or close.

Conclusion:

Gate valves and butterfly valves are essential components in the flow control industry, each with its unique features and applications. Gate valves excel in shut-off capability and high-pressure applications, while butterfly valves offer quick and cost-effective flow control solutions. Understanding the differences between these valves allows engineers and professionals to select the appropriate valve for specific systems, ensuring optimal performance and safety.