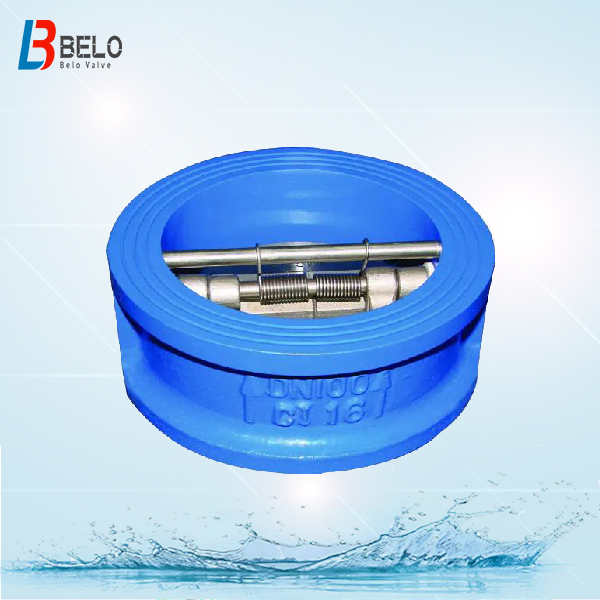

Rubber disc check valve, also known as rubber disc sewage check valve, is widely used in docks, reservoirs, municipal flood discharge, sewage and other projects.

This kind of rubber disc check valve needs to pay attention to many problems when installing it. It needs to meet specific standards before the check valve is installed. So what are the installation requirements for rubber disc check valve?

Preparation before installing rubber disc check valve:

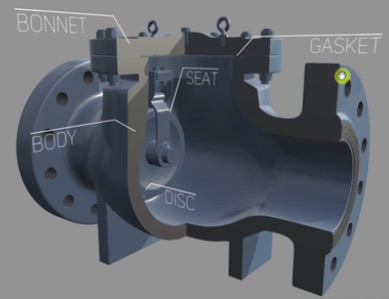

- check whether the real working conditions are consistent with the rubber disc check valve model, installation method, technical parameters, and technical requirements(pressure resistance, or back pressure, temperature resistance, corrosion resistance conditions). Check whether there is any artificial damage inside or outside the valve, check whether there is dirty goods inside the check valve, etc. Check whether there is any burr on the outer surface of the installation pipeline or the connecting flange, whether there is deformation, and whether it is smooth and flat.

Specific requirements for different installation of rubber disc check valve:

- the installation of the grooved type rubber disc sewage check valve should make the inner diameter of the check valve match the outer diameter of the connecting pipe correctly; the depth of the sleeve should meet the corresponding requirements; the surface of the pipeline can be coated with hydraulic glue to seal; the rubber gasket should be properly added between the clamps, and then the connecting bolts should be tightened; if the rubber slow closing check valve adopts an auxiliary liner, for connection, the auxiliary liner and the reserved pipe should be sealed and welded, and the reinforcement should be appropriately increased to improve the strength and rigidity;

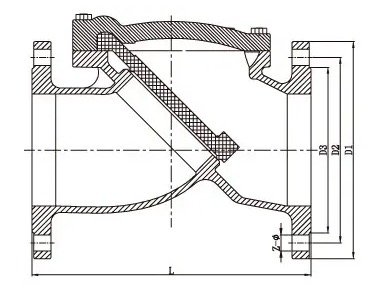

- When the flange rubber disc check valve is installed, the outlet flange size of the drain pipe should be the same as that of the rubber disc check valve. The size of the connecting flange should corresponds to the size of the connecting flange; the specific situation between the flange and the flange should be tested, and a gasket should be installed to ensure the absolute sealing after the connection is tightened; also pay attention not to damage the flange lip of the rubber disc check valve.

- When installing the rubber disc check valve in other ways, referring to the above installation requirements, installation is necessary, but this is not infallible. There are still many other considerations that need to be paid attention to when installing the rubber disc check valves.

- When the nominal diameter of the check valve is greater than DN800, due to the large weight of the valve body, when it is working, the abdominal cavity of the valve body has a large amount of water and water flow impact, a support rod must be added, and the valve body can be stably hoisted for a long time through the lifting ring on the valve body.

- When installing the rubber disc check valve, the bottom valve should be installed at the bottom end of the suction pipe of the water pump, and special attention should be paid to the movement direction of the medium, the normal movement direction of the medium should be consistent with the direction of the arrow indicated on the valve body, otherwise the normal movement of the medium will be cut off.

- The vertical lift check valve should be installed on the horizontal pipelines, and the vertical lift check valve and bottom valve are usually installed in vertical pipelines, and the medium flows from bottom to top, when the rubber disc check valve is closing, water hammer pressure will be generated in the pipeline, which will cause damage to the check valve, pipeline and equipment in severe cases, especially for large diameter pipelines or high pressure pipelines, so the customer for rubber disc check valve should be careful about those requirements.