Butterfly valve can be divided into wafer butterfly valves and flanged butterfly valves according to the connection method. Because the different connection methods, their installation methods are also different. This article will introduce you the installation methods of wafer type butterfly valve and flange butterfly valve:

Belo Valve is a more than 15 years professional manufacturer for industrial valves, like butterfly valves( center line wafer butterfly valve, manual butterfly valve, lever driving butterfly valve, butterfly valve with worm gear box, lug type butterfly valve, soft seal butterfly valves, hard seal butterfly valves, flange butterfly valves, ductile cast iron butterfly valves, stainless steel butterfly valve), gate valves(including DINF4 gate valves, DINF5 gate valves, DIN3352 gate valves, rising stem gate valves, non rising stem gate valves, soft seal gate valves, hard seal gate valves, hydraulic gate valves, sluice valves), globe valves( DIN globe valves, bellows globe valves, electric globe valve), ball valves( welded ball valves, soft seal ball valves, stainless steel ball valves, WCB ball valves, ductile cast iron ball valves, API ball valves), check valves( wafer type check valves, swing check valves, rubber disc check valves, ball type check valve, foot valve/bottom valve), fire protection valves( grooved butterfly valves, grooved gate valves, grooved strainers, grooved check valves), hydraulic control valves,etc.

Installation guidelines for wafer butterfly valve:

The structure of the wafer butterfly valve is relatively short and it needs small space to install. When installing the wafer butterfly valve, use the special flange for wafer type butterfly valve to fix it, and then put the fixed wafer flange into the middle of the flanges at both ends of the pipeline, and use the screws to fasten it through the special flange for wafer butterfly valve and the pipe flange.

The specific installation steps for wafer butterfly valve are as follows:

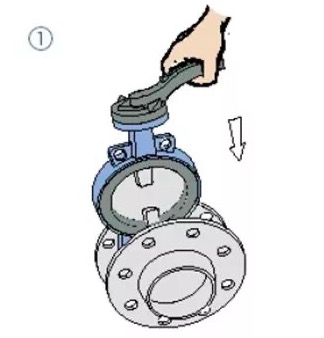

1. place the wafer butterfly valve between the two pre installed special flanges for wafer butterfly valve, and pay attention to align the flange bolts holes with the round holes on the butterfly valve body.

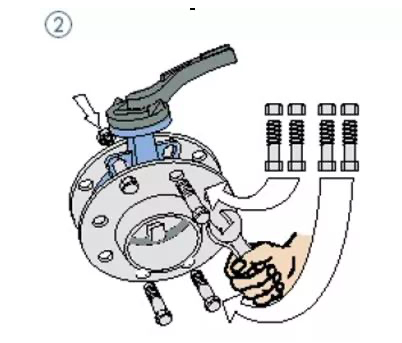

2. Insert the bolts and nuts into the flange holes to connect the valve body to the flanges, and correct the flatness of the flange surface, but be careful not to overtighten the bolts and nuts.

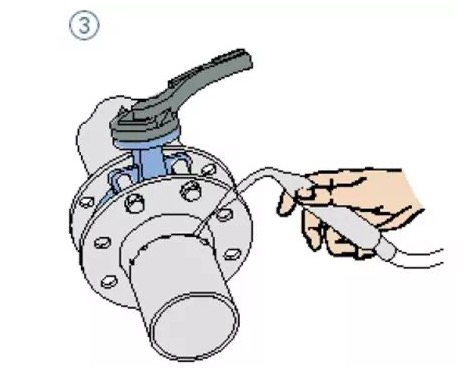

3. Weld the flange on the pipe by spot welding.

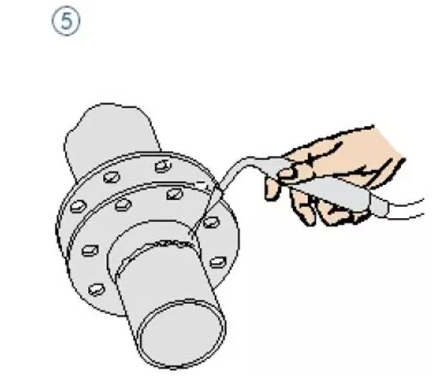

4. Remove the wafer butterfly valve first.

5. Then completely weld the two flanges on the pipe to complete the fixation.

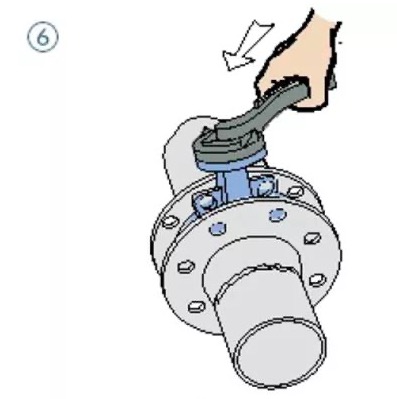

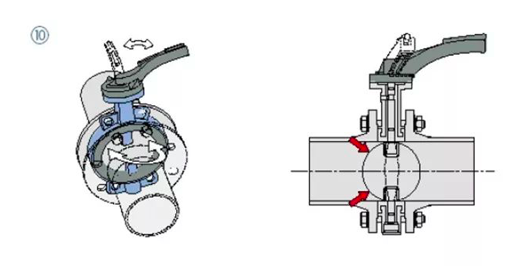

6. After the welded part between the flange and the pipe is cooled, install the wafer butterfly valve, at that point, careful to open the butterfly plate a little.

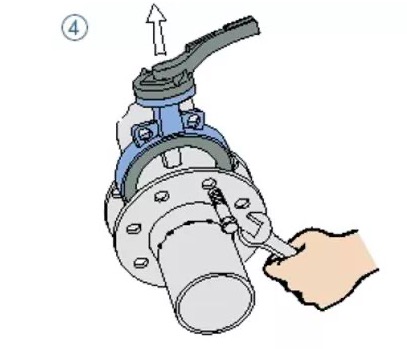

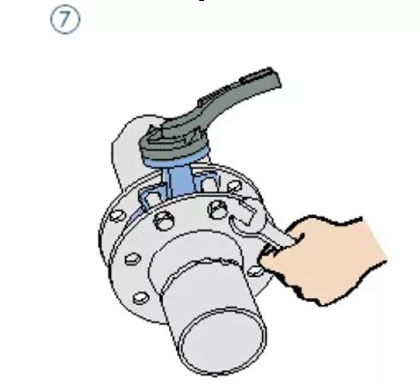

7. Correct the installation position of the butterfly valve again, and tighten the bolts, but be careful not to over-tighten them.

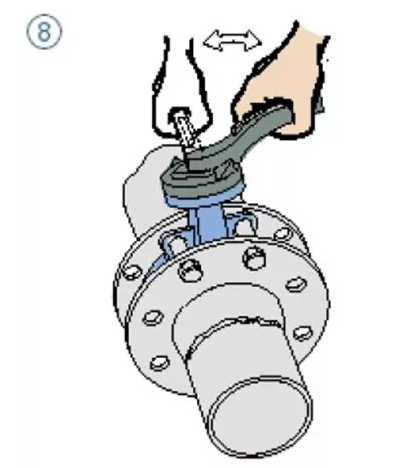

8. Open the butterfly plate fully to ensure that the butterfly plate of the butterfly valve can be opened and closed freely.

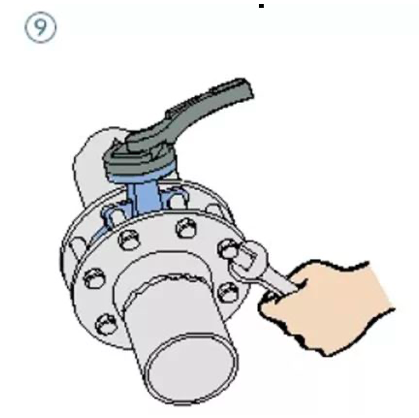

9. Cross the bolts again and tighten evenly.

10. Finally, test the opening and closing of the butterfly valve again to ensure that the butterfly valve can open and close freely.

Installation guidelines for flange butterfly valve:

Flanged butterfly valve comes with flanges, so there is no need to use the special flanges during installation, and the flanges on the butterfly valve body and the pipeline flanges can be directly connected with bolts.

Pay attention to a few points when installing the flange butterfly valve:

1. during installation, the end face between the flange of the butterfly valve body and the upper flange of the pipeline should be parallel, and there should be no skew, otherwise the flange connection part may leak due to insufficient tightening of the bolts.

2. When the flanged butterfly valve is installed on the pipeline, gaskets should be added between the flanges at both ends of the pipeline and the valve body flanges, but double gasket cannot be used.

3. When tightening the bolts, it should be done symmetrically, and the tightening force of each bolt of the flange connect at both ends should be even and consistent.

4. When installing, first install the bolts of the positioning holes on the butterfly valve, and fix the position of the butterfly valve in the center. In addition, when tightening the flange bolts, tighten them symmetrically and alternately, and do not tighten the bolts individually in sequence.

Compared with wafer type butterfly valve, flanged butterfly valve has better sealing performance and is more suitable for large diameter valves. But the use cost and price will also be higher. The flanged butterfly valve has a longer structure and takes up more pipe installation space.