Electric butterfly valve belongs to a variety of electric valve and electric regulating valve. The end connection of electric butterfly valve includes flange type end connection and wafer type end connection; the main sealing forms of electric butterfly valves are resilient rubber soft sealing and metal hard sealing; the electric butterfly valve controls the opening and closing of the butterfly valve through the power signal. This electric butterfly valve can be used as shut-off valve, control valve and check valve in pipeline systems. With manual control device equipped, in the event of a power failure, manual operation can be temporarily used without affecting the use.

| Product name | Electronic butterfly valve/electronic butterfly valve | Nominal pressure | 1.0Mpa,1.6Mpa |

| End connection | Wafer end and flange end | Voltage range | AC220V/110V/380V/24V |

| Advantages | Simple structure, small size, light weight, east to operate | Working temperature | -30℃-130℃ |

| Valve body material | Cast iron, ductile iron, cast steel, stainless steel | Nominal diameter | DN50-DN1200 |

| Valve disc material | SS 304, 316, 316L, nylon plate, al-bronze | Valve seat material | NBR, EPDM, PTFE |

Brief introduction of electric butterfly valve

With the development of the electric valves, there are plenty well-known valve companies at home and abroad producing electric valves, electric butterfly valves are an important device in the field of industrial automatic control. It belongs to a variety of electric valve and electric regulating valve. Electric butterfly valves are widely used in textile, power station, petrochemical, heating and cooling, pharmaceutical, shipbuilding, metallurgy, light industry, environmental protection and other fields. This kind of electric butterfly valves can be used as shut-off valve, control valve and check valve in piping systems. With complete manual control device, electric device or pneumatic transmission device equipped, that electric butterfly valve can meet the specific requirements of different working conditions, which can meet the stringent quality requirements for a very long-lasting application, especially in the metallurgical steel and shipbuilding industries. Electric butterfly valve has a very high reputation among customers all over the world.

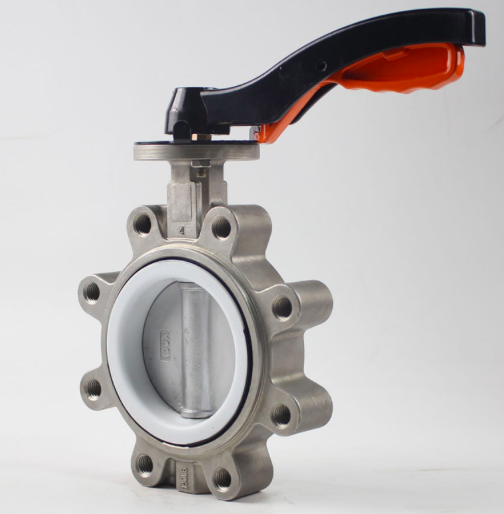

The commonly used electric butterfly valve includes two types: concentric wafer type electric butterfly valve and concentric flange type butterfly valve. The wafer type electric butterfly valve is fixed between the two pipeline flanges with studs. The flange type electric butterfly valve has two flanges on its own valve body, which are connected with the pipeline flanges with bolts.

Working principle of electronic butterfly valve:

The working power of electric actuator on the electric butterfly valve usually includes: AC220V, AC380V,etc. Input signal: 4-20mA, 0-10V and other weak current signals. After the adjustment-type electric actuator and the valve stem are connected, the valve plate is driven to rotate 0°-90° to open and close by the electric power.

Advantages of electric butterfly valve:

1. the electric butterfly valve is convenient and quick to open and close, it is labor saving, and has small fluid resistance, and can be operated frequently.

2. The electric butterfly valve has simple structure, small size and lightweight;

3. The electric butterfly valve can be used to transport the mud with the least accumulation of liquid at the pipe mouth;

4. The electric butterfly valve can achieve good sealing performance under low pressure conditions;

5. The electric butterfly valve has great adjustment performance;

Disadvantages of electric butterfly valve:

1. the applicable pressure and temperature range is small;

2. The sealing performance of electric butterfly valve is a little poor;

Installation and maintenance of electric butterfly valve:

1. During the installation of the electric butterfly valve, the valve disc should stop in the closed position;

2. The opening position of the electric butterfly valve should be determined according to the rotation angle of the valve plate;

3. If the electric butterfly valve is installed together with the bypass valve, the bypass valve should be opened before opening the electric butterfly valve;

4. The electric butterfly valve should be installed according to the manufacturer’s installation instructions. For electric butterfly valves with heavy weight, a firm foundation should set up;

Applications of electric butterfly valve:

Electric butterfly valves are widely used in industrial process automatic control systems in food, environmental protection, light industry, petroleum, chemical industry, water treatment, municipal engineering, paper making, electric power, water treatment and other industries.

Apart from electric butterfly valves, there are also manual lever handle butterfly valves, worm gear box operated butterfly valves, pneumatic actuated butterfly valve:

for more information or price about those butterfly valves, kindly contact us, professional services and reasonable price will be offered: