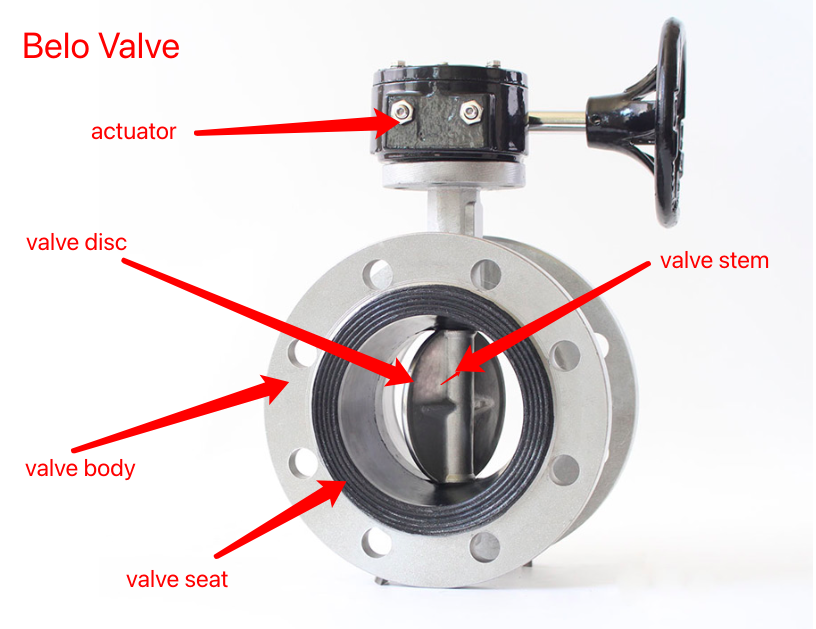

Triple eccentric butterfly valve is for those butterfly valve whose center of valve stem deviates from the center of the disc and the center of the valve body at the same time, and the axis of rotation of the valve seat and the axis of the valve body channel have a certain angle. The sealing material of triple eccentric butterfly valve is mainly metal material, so it is also called triple eccentric metal sealing butterfly valve.

Types of triple eccentric metal seal butterfly valve:

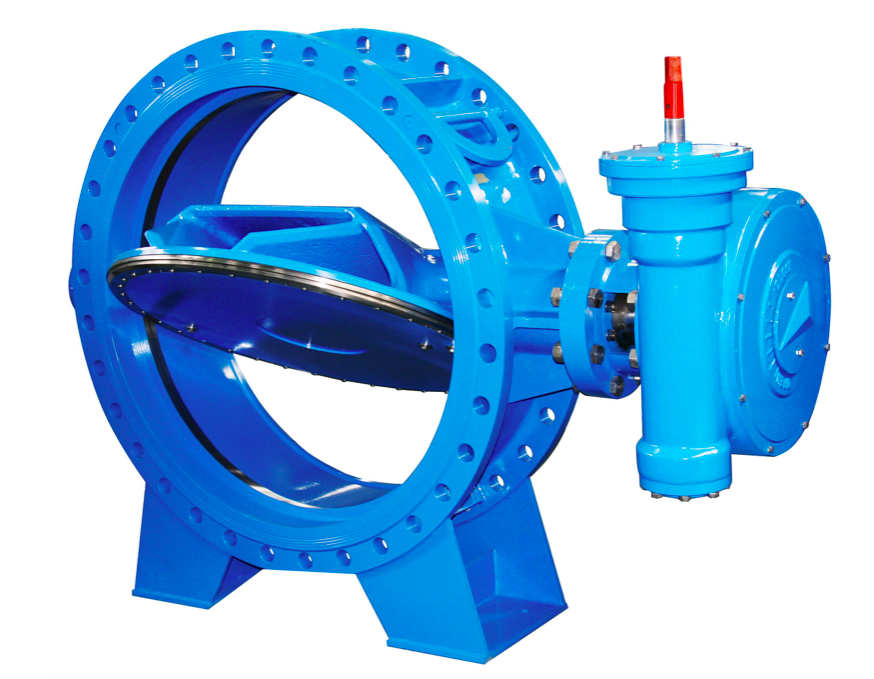

With different end connect, there are triple eccentric wafer type butterfly valve and triple eccentric flange type butterfly valve.

For different body material, there are WCB(carbon steel) triple eccentric butterfly valve and stainless steel triple eccentric butterfly valve.

With different operating device used, there are worm gear box operated triple eccentric butterfly valve, electric actuated triple eccentric butterfly valve and pneumatic actuated triple eccentric butterfly valve;

Development of triple eccentric metal sealing butterfly valve:

① concentric butterfly valve:

The structure feature of concentric butterfly valve is that the center of the valve stem, the center of the disc, and the center of the valve body are in the same position. Its structure is simple and the manufacturing is convenient. The common widely used rubber lined resilient seated soft sealing butterfly valves belong to concentric butterfly valve. The disadvantage of concentric butterfly valve is that the valve disc plate and the valve seat are always squeezed and scratched, its resistance is large, and the wear is fast. In order to overcome the extrusion, scratching, and ensure the sealing performance, the valve seat is basically made of resilient materials such as EPDM or PTFE, because those resilient seat materials are not resistant to high temperature, so there are some limits in its applications. That is why traditionally concentric butterfly valves are thought not to be high temperature resistant.

② single eccentric butterfly valve

In order to solve the extrusion problem between the valve disc and the valve seat in the concentric butterfly valves, the single eccentric butterfly valve is produced. The structural feature of single eccentric butterfly valve is that the axis center of the valve stem deviates from the center of the valve disc plate, so that the upper and lower ends of the disc plate are no longer the axis of the rotation, which disperses, reduces the excessive extrusion between the upper and lower ends of the disc plate and the valve seat. However, in the single eccentric structure, the scraping phenomenon between the disc plate and the valve seat does not disappear during the opening and closing of the valve, the application of the single eccentric butterfly valve is almost similar to that of the concentric butterfly valves, so the application of single eccentric butterfly valves is not that widespread.

③ double eccentric butterfly valve

Double eccentric butterfly valve is one improved design on the basis of the single eccentric butterfly valve, which is most widely used at present. The structural feature of double eccentric butterfly valve is that the axis center of the valve stem deviates not only from the center of the disc plate, also from the center of the valve body. The design of double eccentric enables the disc plate to leave the valve seat quickly after the valve is opened, which greatly eliminates unnecessary excessive extrusion and scratching between the disc plate and the valve seat, reduces the opening resistance, wear and improves the service life of the valve seat. The greatly reducing of the scraping phenomenon enables the double eccentric butterfly valve to use metal seat as the sealing material, which improves the applications of butterfly valves in the high temperature field. However, because its sealing principle is a position sealing structure, that is, the sealing surface of the disc and the valve seat is in lineal contact, the elastic deformation caused by the disc pressing the valve seat produces a sealing effect, so it has a high requirement for the closing position(especially for metal valve seat), its pressure bearing capacity is low, which is why traditionally people think that butterfly valves are not resistant to high pressure and have large leaking problem.

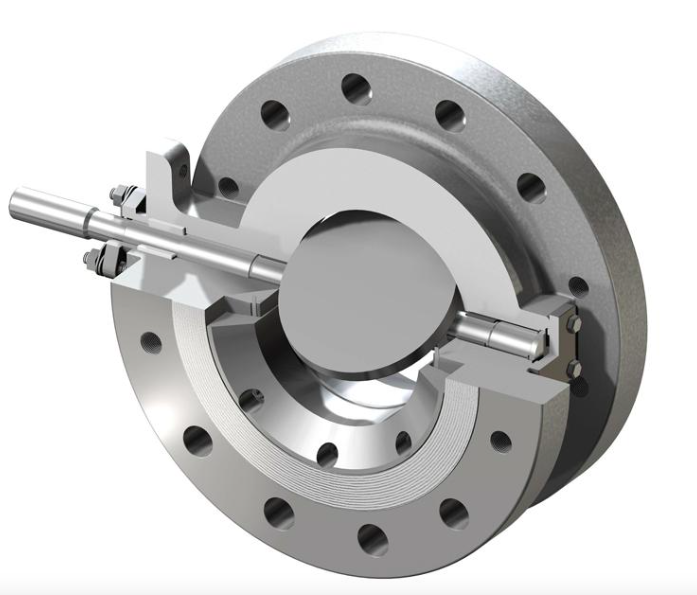

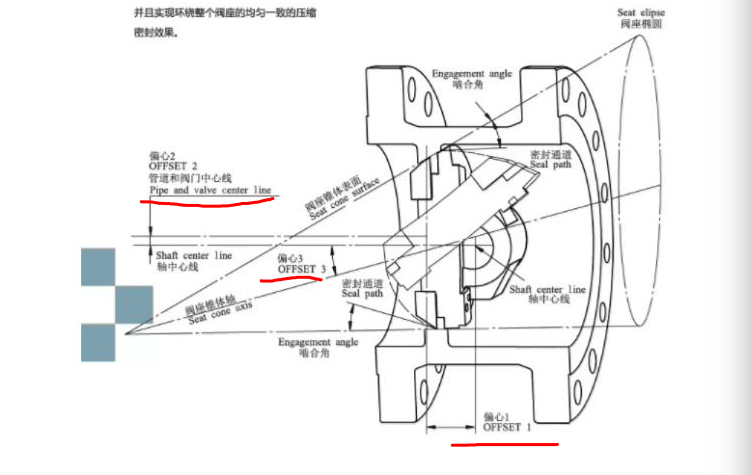

④ triple eccentric butterfly valve(also called triple offset butterfly valve):

To withstand high temperature, metal hard sealing material must be used, but butterfly valve with metal hard sealing material has a large leaking problem; in order to pursue zero leakage, a resilient soft sealing material must be used, while butterfly valve with soft sealing material is not resistant to high temperature. In order to overcome the contradiction of double eccentric butterfly valve, the third eccentric design of butterfly valve was carried out. The structural feature of triple eccentric design is that the conical axis of the disc sealing surface is deviated from the cylinder axis of the valve body while the position of the double eccentric valve stem is eccentric. That is to say, after the third eccentricity, the sealing section of the disc plate in no longer a round circle, but an ellipse, the shape of its sealing surface is also asymmetrical, one side is inclined to the center of the valve body, and the other side is parallel to the center line of the valve body. The third eccentric design fundamentally changes the sealing structure of butterfly valves, it is no longer a positional seal, but a torsion seal, that is, it does not reply on the elastic deformation of the valve seat but completely relies on the contact surface pressure of the valve seat to achieve the sealing effect, which perfectly solve the leaking problem of the metal valve seat, and also because the contact surface pressure is proportional to the medium pressure, the problem that butterfly valves can not be used in high pressure and high temperature is also solved.

Advantages of triple eccentric metal seal butterfly valve:

The triple eccentric butterfly valve is a rotating valve. The three eccentricities are all placed on the valve plate. In the valve manufacturing process, the outer edge of the valve plate adopts a partial outer spherical structure. The outer eccentric spherical surface is polished to a roughness of Ra0.4, the spherical surface is chrome-plated or surfacing Stellite alloy, the hardness is as high as HRC45-60, the triple eccentric butterfly valve can withstand high pressure up to 26Mpa, and the triple eccentric butterfly valve can withstand temperature as low as -196℃, as high as 700℃.the triple eccentric butterfly valve can achieve zero leakage. Due to its special design, triple eccentric butterfly valve has following advantages:

① the triple eccentric butterfly valve has the function of adjusting and cutting off the flow rate, and has strong controlling capacity.

The new triple eccentric butterfly valve is designed with double safety structure. In order to prevent the deformation of the disc plate caused by the influence of fluid pressure and temperature, the dislocation of the valve stem, and the occlusion of the sealing surface, two independent thrust rings are installed on the upper and lower sides of the disc plate, thereby ensuring that the valve can work normally in any conditions. In order to prevent the valve stem from being damaged and flying out and causing accidents, independent mechanisms for preventing the valve stem from flying out are designed at the inner and outer parts of the lower end of the valve;

② triple eccentric butterfly valve has no dead zone, and small opening torque.

The shape of the valve plate in triple eccentric butterfly valve is an elliptical cone, its surface is butt welded with hard alloy, which has excellent wear resistance. The float U-shaped stainless steel valve seat has the function of automatically adjusting the center. When the valve is opening, the elliptical cone sealing surface valve plate first disengages the U-shaped elastic valve seat, then rotate again; when the valve plate is closing, the valve plate rotates, and the valve plate automatically adjusts the center to the elastic valve seat under the action of the eccentric axis, and presses the valve seat to deform the valve seat until the valve seat and the valve plate elliptical conical sealing surface are closely matched. It achieves that the disc plate does not scratch the valve seat when the valve is switched on and off, the torque of the stem is directly transmitted to the sealing surface through the disc plate, and the opening torque is small, thus eliminating the common jumping phenomenon when opening the valve, there is almost no dead zone. This design without dead zone enables the triple eccentric butterfly valve to enter the controllable area almost from 0° to 90°, and its controlling ratio can reach up to 100:1, which is twice that of ordinary butterfly valves.

③ triple eccentric butterfly valve has zero leakage, is resistant to high temperature and high pressure;

The biggest feature of triple eccentric design is that it fundamentally changes the sealing structure of the butterfly valves. It is no longer a positional seal, but a torsion seal, that is, it does not rely on the elastic deformation of the valve seat, but completely relies on the contact surface pressure of the valve seat to achieve the sealing effect. This special kind of sealing structure enables the triple eccentric butterfly valve to achieve hard sealing Level VI and achieve true zero leakage. At the same time, due to the selection of the metal sealing seat and the special structural characteristics of the sealing surface, the triple eccentric butterfly valve is also resistant to high temperature and high pressure.

In addition, the triple eccentric butterfly valve adopts the body material seat structure, which makes the valve structure more compact, and reduces the direct contacting between the valve seat and the mediums, also reduces the erosion degree of the valve seat, which prolongs the service life of the valve seat.

In the new triple eccentric butterfly valve, the valve seat can be replaced easily, and the sealing surface of the disc plate and the disc plate are independent, and the sealing surface of the disc plate can also be replaced, which greatly reduces the maintenance cost.

Applications of triple eccentric butterfly valve:

The triple eccentric butterfly valve is widely used in industrial pipelines such as metallurgy, electric power, petrochemical industry, water supply and drainage, and municipal construction where the medium temperature is ≤425℃, for flow regulating and cutting off.

for more information about triple eccentric butterfly valves, technical parameters or prices, do not hesitate to contact us: