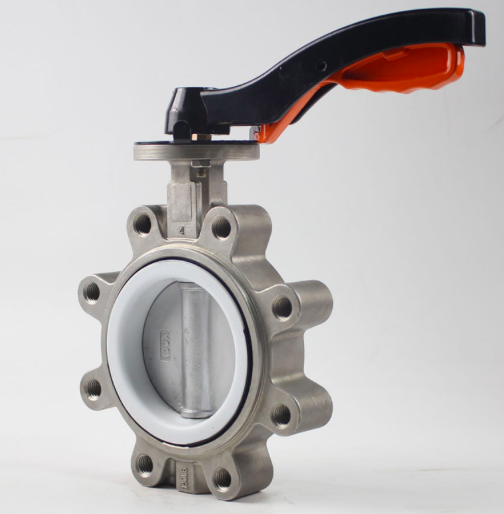

Butterfly valve is one kind of controlling mechanical device which is used widely in the pipelines to connect, shut off and regulate the medium flow. The disc of the butterfly valve is installed in the diameter direction of the pipeline. In the cylindrical passage of the butterfly valve body, the disc rotates around the axis, and the rotation angle is between 0° and 90°. when it rotates to 90°, the butterfly valve is fully open. Butterfly valves have been widely used in many fields such as petroleum, chemical industry, metallurgy, hydro-power and so on;

According to different structure designs, butterfly valve can be divided into concentric butterfly valve, single eccentric butterfly valve, double eccentric butterfly valve, triple eccentric butterfly valve; Among concentric butterfly valve, the widely used ones are soft sealing concentric butterfly valves. The sealing material of soft sealing concentric butterfly valve can be: nitrile rubber(NBR), EPDM, PTFE, FKM; According to end connections, soft sealing concentric butterfly valve can be divided into flange type soft sealing concentric butterfly valve, wafer type soft sealing concentric butterfly valve, welded soft sealing concentric butterfly valve; because the great sealing performance of soft sealing material, soft sealing concentric butterfly valves are widely used in various industries, but soft sealing concentric butterfly valves couldn’t be used for high pressure, high temperature, corrosion resistance, wear resistance industries.

Advantages and disadvantages of each sealing material in soft sealing butterfly valve

1. Compared with other rubbers, EPDM rubber for soft sealing butterfly valves has great advantages:

1.1. the soft sealing butterfly valve is cost effective: Among the commonly used rubber materials, EPDM has the lightest green rubber density and can be filled in large quantities, therefore reducing the cost of the rubber compounds;

1.2. the rubber material of soft sealed butterfly valve is resistant to aging, wear, sunlight, heat, moisture, radiation, suitable for weak acid and weak alkali mediums, and has good insulation performance;

1.3. the applicable temperature range of soft sealing butterfly valve with EPDM sealing material is ≤120℃,the maximum temperature of EPDM seated butterfly valve can be 150℃。

2. The NBR sealing material in soft sealed butterfly valve has good oil resistance, heat resistance and wear resistance, as well as good water resistance, air tightness and excellent adhesion properties. NBR lined soft sealing butterfly valves are widely used in petroleum pipelines, but its disadvantages are poor low temperature resistance, poor ozone resistance and poor insulation, and is not as elastic as EPDM material. The applicable working temperature of NBR seated soft sealing butterfly valve is ≤80℃。

3. PTFE material in soft sealing butterfly valve has strong acid and alkali resistance, resistance to various organic solvents, and at the same time, PTFE material is resistant to high temperature and can be used continuously at 200℃, the high temperature resistance of PTFE material successfully solves the application problems of soft sealing butterfly valve in chemical and petroleum, pharmaceutical and other industries; the working temperature of PTFE lined butterfly valve is ≤200℃.

4. FKM material in soft sealing butterfly valve has good corrosion resistance, the stability of FKM material is better than other rubber materials in mediums like organic liquid(fuel oil, solvent, hydraulic medium,etc), concentrated acid(nitric acid, sulfuric acid, hydrochloric acid), high concentration hydrogen peroxide,and other strong acid mediums; FKM material has good weather resistance and ozone resistance, high tensile strength and hardness, good vacuum resistance and flame retardancy; while FKM material has poor resilience and insulation; the applicable working temperature of FKM seated butterfly valve is ≤180℃。

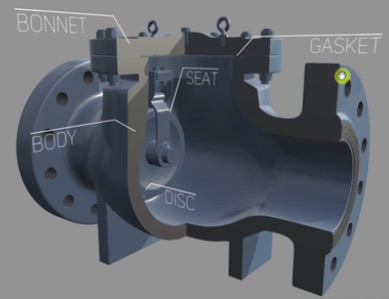

Apart from soft sealing concentric butterfly valves, there also are some metal hard sealing butterfly valves, but the structure of most of the hard sealing butterfly valves are eccentric.

for more information or prices about hard sealing butterfly valves or soft sealing butterfly valves, kindly contact us: