Gate valve, also known as sluice valve, is one widely used industrial valves, which is used to connect and cut off the mediums, and can not be used to regulate and throttle.

There are many various types of industrial valves, according to different stem design, there are OS&Y gate valve( rising stem gate valves) and non rising stem gate valves. According to sealing structure, there are resilient seated gate valves, metal to metal hard sealed gate valves.

according to different standard, there are BS5163 gate valves, DIN 3352 gate valves, GB gate valves, API gate valves, JIS gate valves,etc.

With different operating devices used, there are manual hand wheel operated gate valve, electric actuated gate valves,pneumatic actuated gate valves, etc.

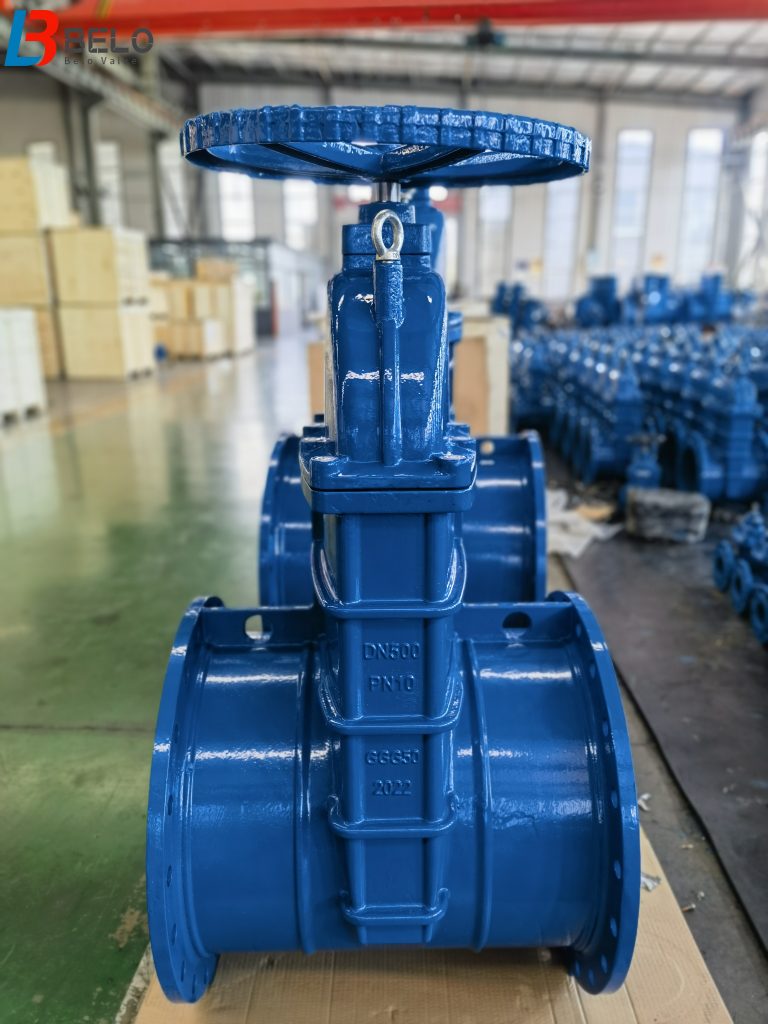

According to different body material used, there are gray cast iron gate valves, ductile iron gate valves, carbon steel WCB gate valves, stainless steel gate valves, forged steel gate valves.

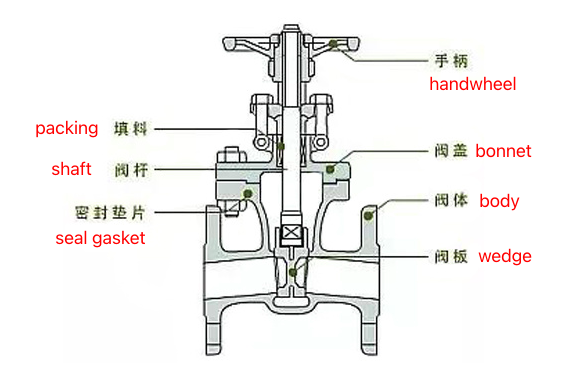

Main parts of a gate valve:

The gate valve is mainly composed of valve body, valve bonnet, valve wedge, valve seat and operating device,etc. Now we are going introduce you those main components one by one:

1. About the valve body:

the valve body of the gate valve is directly connected with the pipeline, which is the main component to bear the pressure of the flowing mediums. The valve body is also the main part to install the valve seat, bonnet. The valve wedge is also placed vertically inside the valve body, which will move up and down to connect and cut off the medium flow. That is why the cavity height of the gate valve body is relatively large.

The structure of the valve body of the gate valve determines the connection between the valve body and the pipeline, and the valve body and the bonnet. The blank of the valve body can be cast, forged, forged welded and tube sheet welded. Cast valve body is generally used for gate valve whose diameter is DN≥50mm, and forged valve body is generally used for gate valve whose diameter is DN≤50mm.

2. About the bonnet:

the bonnet is the main pressure bearing part that is connected with the valve body, and forms a pressure chamber with the valve body, and has a stuffing box within. For small and middle diameter valves, there is a structure on the bonnet to support other components such as stem nut or operating devices.

3. About the valve stem:

The valve stem is directly connected with the valve stem nut or the transmission device, the polished rod part forms a sealing pair with the packing, which can transmit torque and play the role to open and close the gate wedge.

4. About the valve wedge:

The wedge is the opening and closing part of the gate valve, the opening, closing, its sealing performance and service life mainly depend on that valve wedge, which is the key pressure-control part of the gate valve. According to the structure of the wedge, it can be divided into parallel type gate valve and wedge type gate valve.

5. About the valve seat:

The valve seat is fixed on the valve body and the valve plate to form a sealing pair by rolling, welding, screw connection,etc. The valve seat sealing ring can be directly welded with metal on the valve body to form a sealing surface according to customer requirements. For cast iron gate valve, stainless steel gate valve, and copper alloy gate valves, the sealing surface can also be directly machined on the valve body.

6. About the operating device:

The operating device can directly transmit electricity, air and man power to the stem or stem nut. In power plants, hand wheels, valve covers, transmission mechanisms, connecting shafts and universal couplings are often used for long distance operating.

For more questions about those industrial gate valves, or other industrial valves, kindly contact us: