Gate valve and butterfly valve are both vary popular industrial valves used in industrial pipelines. Even gate valve and butterfly valve both can be used as controlling devices, while there are still some difference between gate valve and butterfly valves, for example, gate valve and butterfly valve have different working principle, different structures, etc. Today we are going to introduce you the difference between gate valve and butterfly valves.

1. the definitions of gate valve and butterfly valve are different.

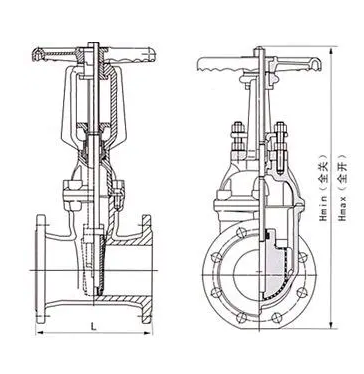

1.1. Definition of gate valve: gate valve, also called sluice valve, is a popular opening and closing industrial valve. The movement direction of the gate valve is perpendicular to the direction of the fluid. Gate valve can only be fully opened and fully closed, and can not be used as adjustment and throttling. When the gate valve is fully opened, the fluid resistance in the gate valve is smaller than that of the butterfly valve.

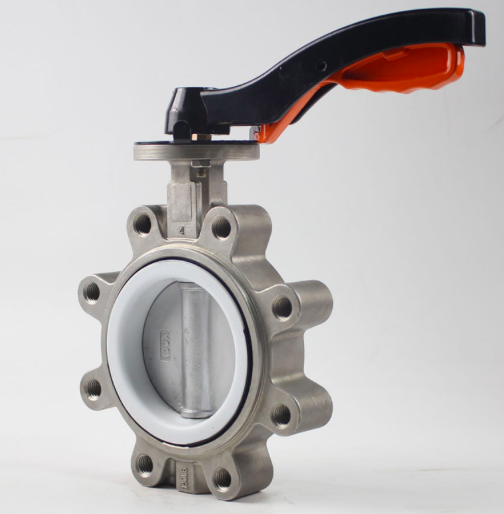

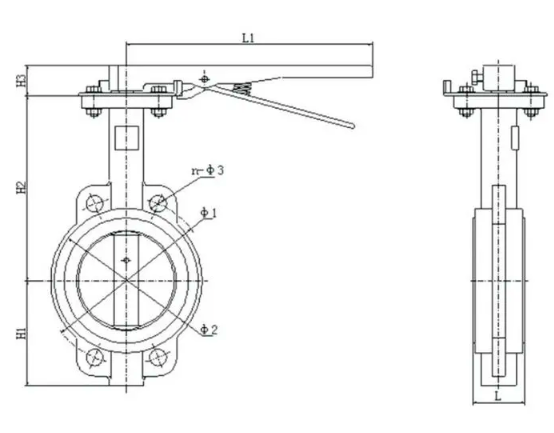

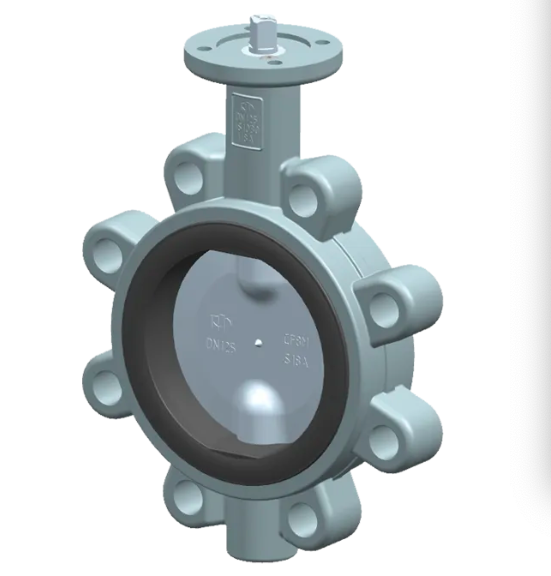

1.2. Definition of butterfly valve: butterfly valve is one kind of simple regulating valve. The opening and closing switch of butterfly valve is a circular disc, which rotates around the valve stem inside the body of butterfly valve to realize the opening and closing of the butterfly valve. Butterfly valve can not only be used to cut off the medium flow in the pipeline, also can be used as the throttling device. It is usually less than 90°for the butterfly valve from fully opened position to the fully closed position. When the butterfly valve is fully opened, the thickness of the valve disc is the only resistance to the fluid flow, so the flow resistance of butterfly valve is very small.

2. the working principles of gate valve and butterfly valve are different.

2.1. Working principle of gate valve: the gate valve is one kind of straight stroke industrial valve, that is, the valve stem drives the valve plate to move vertically up and down to realize the opening and closing of the gate valve, so when the gate valve is fully opened, the flow resistance of gate valve is small, but because the opening height of gate valve is high, so the opening and closing time of gate valve is long.

2.2. Working principle of butterfly valve: butterfly valve belongs to angular stroke industrial valve, that is, the valve disc of the butterfly valve rotates 90°around the valve shaft to complete the opening and closing of the butterfly valve, so the opening height of the butterfly valve is only a quarter of the diameter of the channel, so the opening and closing of butterfly valve is fast.

3. gate valve and butterfly valve have different applications.

3.1. Application of gate valve

3.1.1 Gate valves can be used for oil and natural gas pipelines. The flat gate valve with diversion hole also facilitates the cleaning of the pipelines.

3.1.2 Gate valves can be used for the delivery pipelines and storage equipment of refined oil products.

3.1.3 Gate valves can be used for extraction well equipment of oil and natural gas.

3.1.4 Gate valves can be used for pipelines with mediums with suspended particles.

3.1.5 Gate valves can be used for urban natural gas delivery pipelines.

3.1.6 Gate valves can be used for water pipelines. (drinking water, sewage,etc)

3.2 Applications of butterfly valves:

3.2.1. Since the butterfly valve has relatively large pressure loss compared with the gate valve and ball valve, so butterfly valve is suitable for the pipeline system where the pressure loss requirements are not strict.

3.2.2 Since butterfly valves can not only be used to cut off and connect the fluid, also can be used as throttling and regulating device, so for those pipelines where flow adjustment is required, butterfly valves are one great selection.

3.2.3 Due to the limitation of structure and sealing material of butterfly valve, it is not suitable for high temperature and high pressure piping system. Usually the working temperature of butterfly valve is below 300℃, and the nominal pressure of butterfly valve is below PN40.

3.2.4 Because the face to face length of butterfly valve is short, and butterfly valve can be made into a large diameter valve, so the butterfly valve should be selected in the occasion where the structural length required is short or the valve required has large diameter(such as DN1000 or above).

3.2.5 Since the butterfly valve can complete the opening and closing just through rotating 90°, the butterfly valve should be selected in the occasions where the fast opening and closing of the valve is required.

4. whose price is high, gate valve or butterfly valve?

Generally speaking, the price of gate valve is higher than that of the butterfly valve, because when the material used and diameter are the same, the butterfly valve has a simple structure, and the material used for butterfly valves is fewer, so the price of butterfly valve is much lower than that of the gate valve. And among those various types of butterfly valves, the price for concentric wafer butterfly valve is lower than that of other types of butterfly valves.

5. gate valve and butterfly valve have different structural classification.

5.1 structural types of gate valve

With different structures, gate valves can be divided into rising stem gate valve( also called OS&Y gate valve) and non rising stem gate valves.

5.2 structural types of butterfly valve

With different structures, butterfly valves can be divided into concentric butterfly valves and eccentric butterfly valves. Concentric butterfly valves can be divided into wafer type concentric butterfly valves, flanged concentric butterfly valves, wafer lugged concentric butterfly valve. Eccentric butterfly valves can be divided in single eccentric butterfly valve, double eccentric butterfly valve and triple eccentric butterfly valve( also called three eccentric butterfly valve).

Belo Valve is a more than 15 years professional manufacturer for industrial valves, like butterfly valves( center line wafer butterfly valve, manual butterfly valve, lever driving butterfly valve, butterfly valve with worm gear box, lug type butterfly valve, soft seal butterfly valves, hard seal butterfly valves, flange butterfly valves, ductile cast iron butterfly valves, stainless steel butterfly valve), gate valves(including DINF4 gate valves, DINF5 gate valves, DIN3352 gate valves, rising stem gate valves, non rising stem gate valves, soft seal gate valves, hard seal gate valves, hydraulic gate valves, sluice valves), globe valves( DIN globe valves, bellows globe valves, electric globe valve), ball valves( welded ball valves, soft seal ball valves, stainless steel ball valves, WCB ball valves, ductile cast iron ball valves, API ball valves), check valves( wafer type check valves, swing check valves, rubber disc check valves, ball type check valve, foot valve/bottom valve), fire protection valves( grooved butterfly valves, grooved gate valves, grooved strainers, grooved check valves), hydraulic control valves,etc.

for any questions about the industrial gate valves and butterfly valves, kindly contact us: