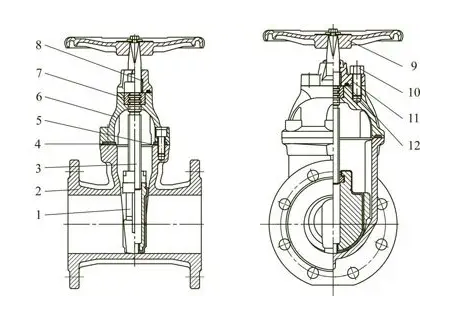

Gate valve(also known as sluice valve) is the most common industrial valve, widely used in petroleum, petroleum, petrochemical, power station, long distance pipelines and ship building and other industrial fields. As one kind of fluid controlling device, the opening and closing part of the gate valve is the gate plate, the plate moves up and down to realize the opening and closing of the gate valve and to cut off and connect the medium flow.

Type of gate valves:

According to different stem structure, gate valve is divided into rising stem gate valve( os&y gate valve) and non rising stem gate valve.

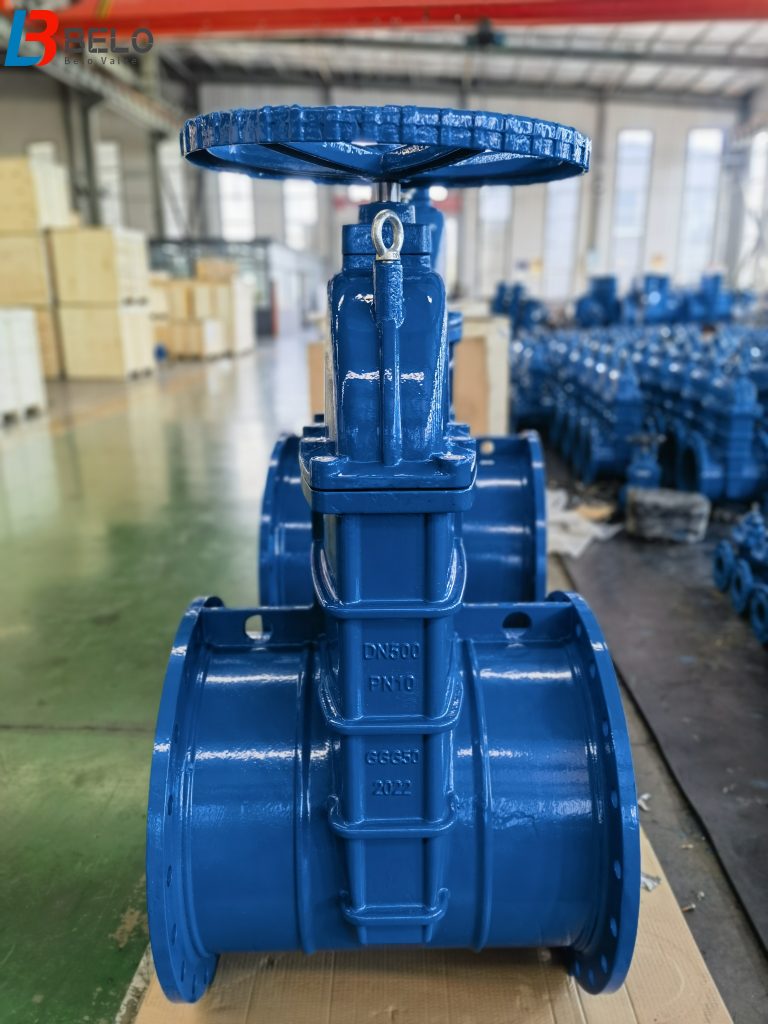

According to different body material used, gate valve can be divided into gray cast iron gate valve, ductile cast iron gate valves, stainless steel gate valves and cast steel gate valves(carbon steel WCB gate valves).

With different sealing material used, there are resilient seated gate valves( soft sealing gate valves), metal to metal seated gate valves( metal hard sealing gate valves).

With different standards, there are GB gate valves, API gate valves, ANSI AWWA gate valves, BS gate valves, DIN gate valves, and JIS gate valves,etc.

With different manufacturing technology used, there are casting gate valves and forged gate valves. Casting gate valves are usually for gate valves with diameter DN≥50mm, forged gate valves are usually for gate valves with diameter DN<50mm.

Why do gate valves fail or leak?

As a very important cutting-off and connecting device in industrial pipelines, if the gate valve fails or leaks, which is easy to bring hidden dangers to the pipelines and equipment and facilities, even affect the safety of workers and equipment. If we can have a good understanding about the gate valve structure and the working principle of gate valve, which can help us to operate gate valve in a correct way, and grasp the operating status of the gate valve better. If the gate valve leaks, we can take the correct disposal method at the first time to reduce economic losses and reduce the probability of accidents.

The leakage of gate valve can be divided into internal leakage and external leakage. There are many reasons to cause the leakage of gate valve, if we want to take some methods to fix a leaking gate valve, we have to have a deeper understanding about why that gate valve is leaking.

1. The machining accuracy of the wedge-shaped sealing ring is low, resulting in internal leakage of the gate valve.

The wedge sealing can be divided into two types, one is metal hard sealing, also known as metal wedge rings; the second is soft sealing, also known as composite graphite wedge rings. If the precision of the wedge-shaped sealing ring is low, it is easy to cause internal leakage of the gate valve.

2. the working and operating conditions are unstable, which leads the internal leakage of the gate valve.

If the working and operating condition of gate valve is unstable, its pressure and temperature may vary greatly, which makes the sealing ring to withstand greater impact pressure, scouring force and deformation, resulting in the larger gap between the sealing ring and the valve body, which cause the internal leakage of the gate valve.

3. the maintenance quality of the gate valve is not good enough, which results in the internal leakage of the gate valve.

During the process of disassembling the gate valve for maintenance, the sealing surface is not cleaned when the wedge-shaped sealing ring is installed, some fine particles and impurities are left inside. These fine impurities may scratch the sealing surface during the operation of the gate valve. It may form penetrating scratches to the sealing surface, which can cause the internal leakage of the gate valve.

4. the wedge-shaped sealing ring is corroded by the medium, which results in the leakage of the gate valve.

When designing the wedge-shaped sealing ring, it is necessary to pay more attention to the strength and corrosion resistance of the sealing ring. The surface hardness of the sealing ring is smaller than the hardness of the bonnet sealing layer, it must also meet the requirements to form plastic deformation under the action of external force. Under long time working, the wedge-shaped sealing ring may be corroded by the medium, resulting in leakage of the gate valve.

5. the operating actuator of the gate valve is not opened or closed in the correct place, resulting the internal leakage of the gate valve.

The opening and closing of the gate valve is controlled by the types of actuators. The actuator relies on liquid, gas, electricity or other energy, and convert them into a driving action through a motor, a cylinder or other devices to drive the gate valve to be fully opened or fully closed. If the actuator is not opened or closed in the correct place, which means the gate valve is not fully opened or fully closed, resulting in the internal leakage of the gate valve.

6. there are some defects on the body of the gate valve, which results in the leakage of the gate valve.

The casting valve body of the gate valve may often have casting defects, such as pores, slag inclusions, cracks, sand holes, etc. If these defects are not found in the factory, or proper repair measures are not taken after those casting defects are found, those cast defects will cause leakage of the gate valve during its working.

How to fix a leaking gate valve?

1. fix the valve body pressure plate and increase the bolt preload.

When there is leakage or small amount of leakage inside the gate valve, the priority is to tighten and fix the pressure plate of the valve body, and strengthen the pre-tightening force between the pressure plate and the wedge-shaped sealing ring by raising the bolt, which can help the plastic deformation of the sealing ring, and reduce the gap between valve body, pressure plate and the sealing ring, and the leakage phenomenon of the gate valve self-sealing can be avoided. If the amount of leakage does not change significantly when tightening and fixing the bolts, the measure to tighten the bolts should be stopped, and other measures should be taken instead.

2. inject the sealant through the grease injection hole.

When a small amount of internal leakage occurs inside the gate valve, some grease can be injected to the sealing surface or packing through the grease injection hole to temporarily relieve the internal leakage of the gate valve. When it is convenient for inspection and maintenance, the gate valve can be disassembled, and that gate valve can be returned to the factory for repair.

3. weld to strengthen the gap between the valve body, stuffing box and pressure plate.

To deal with the self sealing leakage of the gate valve, it is necessary to disassemble the handwheel of the gate valve and valve frame. First, working with the technicians to grasp and adjust the work conditions on site, then after the gate valve is fully opened, remove the fixed valve frame. Rotating the valve frame to ensure the valve stem did not rise up and fall down, then start to disassemble the valve frame. After disassembling the valve frame, the valve body should be exposed on the pressure plate of the valve, and the gap between the pressure plate and the valve body should be sealed and welded. Considering the reassembly process of the valve frame after the leakage position is welded or sealed, the welded gap size should be between 5mm and 8mm, and the position of welding angle and the pressure plate should form a 45°angle, then polish the welded area according to actual assembly situation.

4. check those components of actuator.

The components of the actuator are not set into the accurate position, they are not in the right position to fully open and close the gate valve. First, fully open and close the gate valve manually, then adjust the zero position of the actuator to ensure that the actuator can fully open and fully close the gate valve accurately.

5. repair welding the valve body or return the leaking gate valve back to the factory for repair or replacement.

When the valve body of gate valve is leaking, the gate valve manufacturer should repair the defects of the valve body, or replace the leaking gate valve. Before repairing or replacing, it is necessary to have a correct judge about the defects on the valve body. It is not allowed to repair the penetrating cracks,penetrating defects and shrinkage porosity exceeding a certain area. In those cases, the leaking gate valve can only be replaced by the valve manufacturer. For those defects which can be repair welded, an appropriate welding process should be formulated, the welding method, electrode material, and post-weld stress relief method should be determined, and appropriate non destructive testing should be carried out on the welded position to ensure that the repair welding meets the relative requirements.

There are many reasons to cause the leakage of a gate valve, sometimes it is because of the defects of the gate valve itself, sometimes due to the inappropriate operation, or the quality of the gate valve is poor,etc. So once the gate valve you are using is leaking, firstly you should find what is the reason to cause the leakage, then formulate the proper repairing solution, or you can find the professional worker to repair them.

Belo Valve is a more than 15 years professional manufacturer for industrial valves, like butterfly valves( center line wafer butterfly valve, manual butterfly valve, lever driving butterfly valve, butterfly valve with worm gear box, lug type butterfly valve, soft seal butterfly valves, hard seal butterfly valves, flange butterfly valves, ductile cast iron butterfly valves, stainless steel butterfly valve), gate valves(including DINF4 gate valves, DINF5 gate valves, DIN3352 gate valves, rising stem gate valves, non rising stem gate valves, soft seal gate valves, hard seal gate valves, hydraulic gate valves, sluice valves), globe valves( DIN globe valves, bellows globe valves, electric globe valve), ball valves( welded ball valves, soft seal ball valves, stainless steel ball valves, WCB ball valves, ductile cast iron ball valves, API ball valves), check valves( wafer type check valves, swing check valves, rubber disc check valves, ball type check valve, foot valve/bottom valve), fire protection valves( grooved butterfly valves, grooved gate valves, grooved strainers, grooved check valves), hydraulic control valves,etc.

For any fail questions about the gate valves or other industrial valves, you can consult us, a professional advice will be offered for your reference.

other articles about gate valves:

1. Introduction of stainless steel gate valves and advantages of stainless steel gate valve

2. What is the difference between gate valve and ball valve?

4. About gate valves-Definition,Application, types, disadvantages and advantages, components

5. How to install gate valves?

6. What are the parts of a gate valve?

7. What is the gate valve or sluice valve?

8. The difference between gate valve and globe valve

9. Introduction about gate valves-Types, Model Nos and pictures