Gate valve is one kind of cutting off industrial valves, whose valve plate moves up and down to connect and shut off the medium flow. Gate valve can only be fully opened and fully closed, and can not be used for regulating and throttling.

There are various types of gate valves, like rising stem gate valves, non rising stem gate valves, soft sealing gate valves, metal hard sealing gate valves, ductile iron gate valves, stainless steel gate valves, DIN gate valves, API gate valves, BS gate valves, ANSI AWWA gate valves,etc.

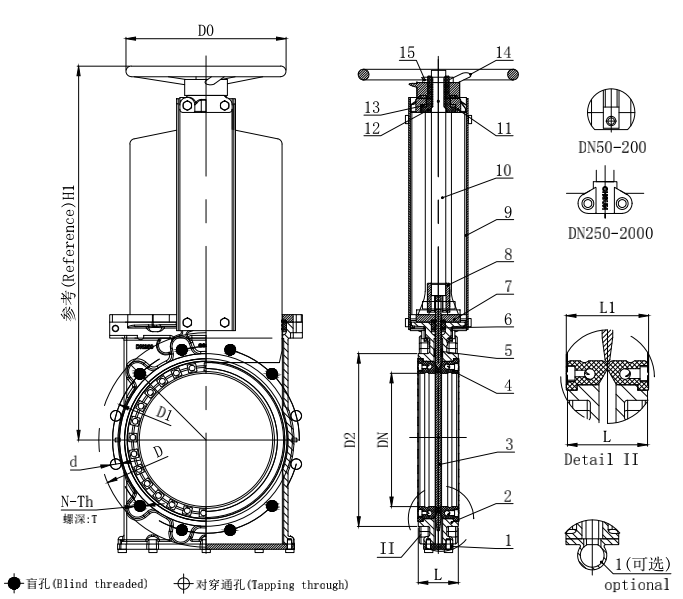

knife type gate valves is also one kind of gate valve. With different plate structure, gate valve can be divided into flat plate gate valve and knife wedge gate valve. And for different end connections, there are flanged knife type gate valve, wafer type knife gate valve, lugged knife gate valve.

The difference between knife gate valve and ordinary gate valve:

The difference between the knife gate valve and the ordinary gate valve is that: the structure of knife gate valve is simple, the opening and closing part of the knife gate valve is one knife-shaped plate, the movement of the plate is perpendicular to the direction of the fluid. Knife gate valves are small in size, flexible in operation and easy to install. Knife type gate valves are suitable for mediums with high viscosity and solid particles. The knife gate valve is mainly relying on its knife-shaped valve plate to cut off the medium flow. The valve plate of knife gate valve can be made into an integral rigid plate or an elastic plate, the elastic valve plate can be slightly deformed to improve the sealing performance. Compared with ordinary gate valves, knife type gate valve has advantages like followings:

- U-shaped gasket of knife type gate valve has good sealing effect.

- The full bore design adopted in the knife gate valve enables the mediums to pass through smoothly. At the same time, for those dirty mediums, knife type gate valve is easier to install, disassemble, and maintain. The sealing parts of the knife gate valve can be replaced without removing the knife gate valve, which makes the maintenance of knife type gate valve easier.

- The plate of the knife gate valve can work like a guillotine,has a great effect for cutting off and can cut off all kinds of sundries in the mediums, which can solve the leaking phenomenon of those mediums with lumps, particles and fibers after the gate valve is closed.

- Compare with ordinary gate valves, knife type gate valve has smaller face to face length, small volume, small flow resistance, light weight, it is also material saving.

Although the price of knife type gate valve is about 20% higher than that of ordinary gate valves, while its excellent performance has been generally accepted by the market.

For gate valves or knife gate valves, they both have their specific advantages and disadvantages, we should select the proper valves according to the real working conditions, like what is the medium? What is the working temperature and pressure? Even how much is the budget? If you have no idea what kind of gate valve or knife gate valve should be used, kindly contact us: